Method for producing anode for aqueous lithium ion secondary battery, and method for producing aqueous lithium ion secondary battery

A manufacturing method and secondary battery technology, applied in the direction of electrode manufacturing, secondary battery, electrode electrochemical treatment, etc., can solve the problems of narrow potential window, active material limitation, etc., to improve the working voltage, inhibit reduction decomposition, and inhibit The effect of electronic transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0142] 1. Preliminary experiment

[0143] The effect of forming a film on the surface of the negative electrode was confirmed by the following preliminary experiments.

reference example 1

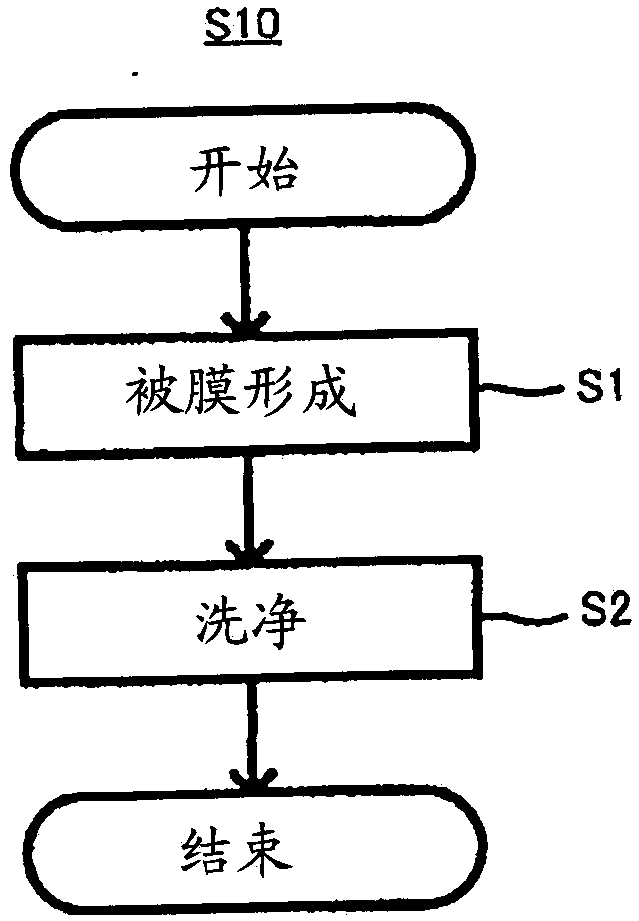

[0145] (manufacture of negative electrode)

[0146] Using graphite sheet as negative electrode 1M LiPF was dissolved in a non-aqueous solvent (EM:DMC:EMC=3:4:3) 6 The resulting nonaqueous electrolyte solution and metal lithium as a counter electrode were used to fabricate a nonaqueous lithium ion secondary battery. Discharge the fabricated battery at 0.1mA to 0.5V at 25°C, and at 0.5V (vs.Li / Li + ) for 10 hours, and then charged to 3 V at 0.1 mA, thereby forming a film on the graphite sheet. The battery is disassembled, the negative electrode is taken out, and the surface of the negative electrode is washed with EMC to remove the residue, and the negative electrode with a film formed on the surface is obtained.

[0147] (Manufacture of aqueous lithium-ion batteries)

[0148] Using the negative electrode with the film formed on the surface as described above, the SUS plate on which gold was vapor-deposited as the counter electrode, the Ag / AgCl electrode as the reference el...

Embodiment 1

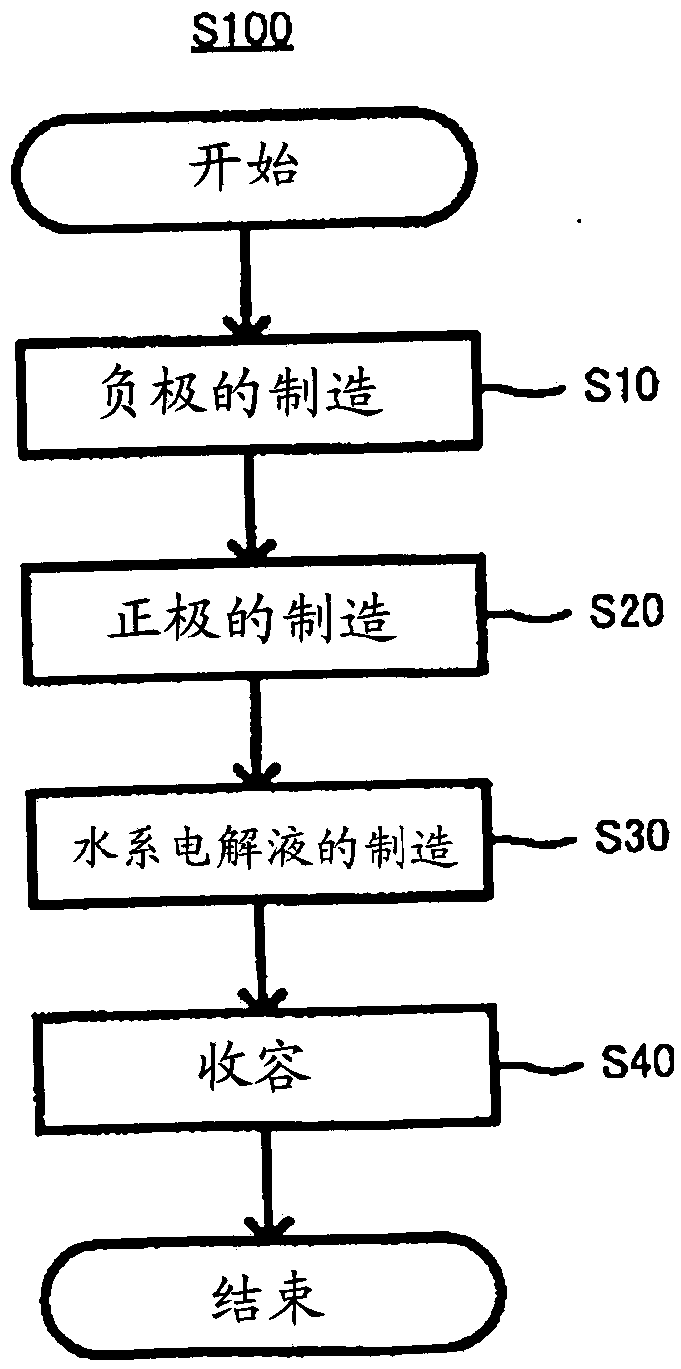

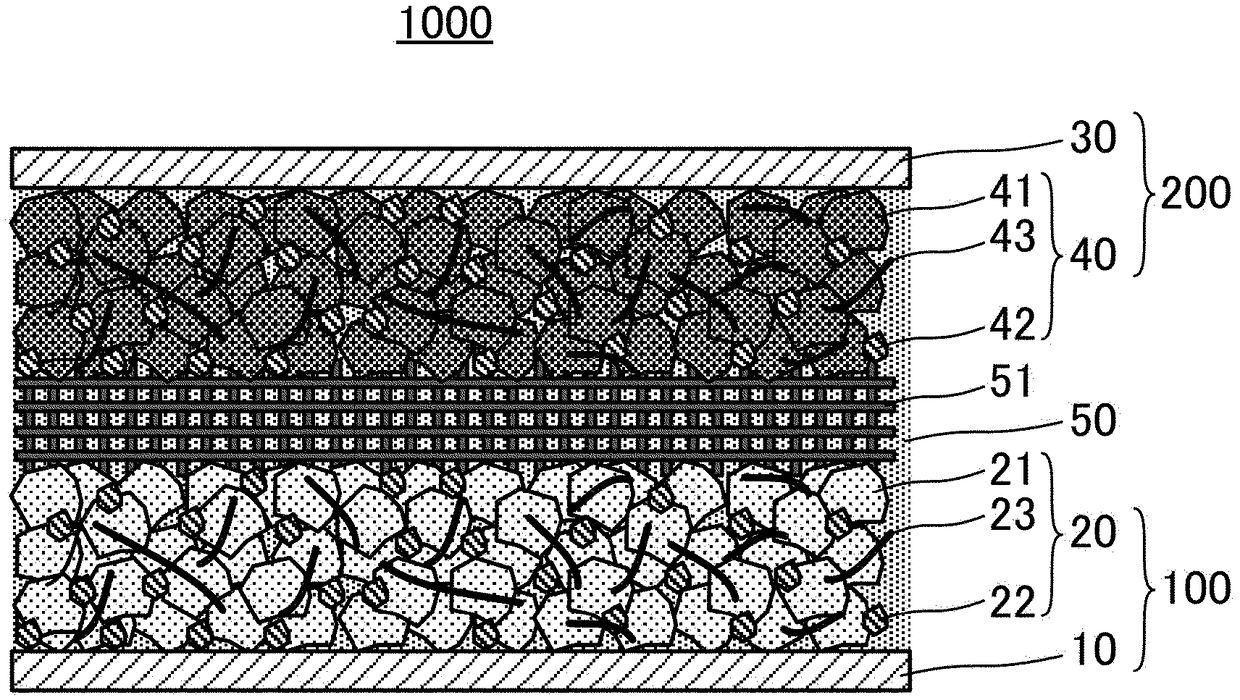

[0173] (manufacture of negative electrode)

[0174] The negative electrode slurry comprising negative electrode active material (LTO), conductive additive (carbon black), binding agent (PVdF) in the ratio of 85:10:5 by mass ratio is coated on the negative electrode current collector (the above-mentioned graphite sheet) and dried to obtain a negative electrode. A coating was formed on the obtained negative electrode under the same conditions as in Reference Example 1 to manufacture a negative electrode having a coating on its surface.

[0175] (production of positive electrode)

[0176] The positive electrode active material (LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 ), a conductive additive (carbon black), and a positive electrode slurry of a binder (PVdF) were coated on a positive electrode current collector (Ti foil) and dried to manufacture a positive electrode.

[0177] (Manufacture of water-based lithium-ion secondary batteries)

[0178] Using the negative electrode with the film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com