Tubular reactor for lithium flow battery

A tubular reactor and liquid flow battery technology, which is applied in the direction of fuel cells, fuel cell additives, regenerative fuel cells, etc., can solve the problem of not being able to fully utilize the high energy density of lithium flow battery electrode slurry and restricting grid energy storage systems Large-scale application, affecting the overall performance of lithium flow batteries and other issues, to achieve good space utilization and adaptability, improve the effective reaction area, and reduce the total amount of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described through embodiments below in conjunction with the accompanying drawings.

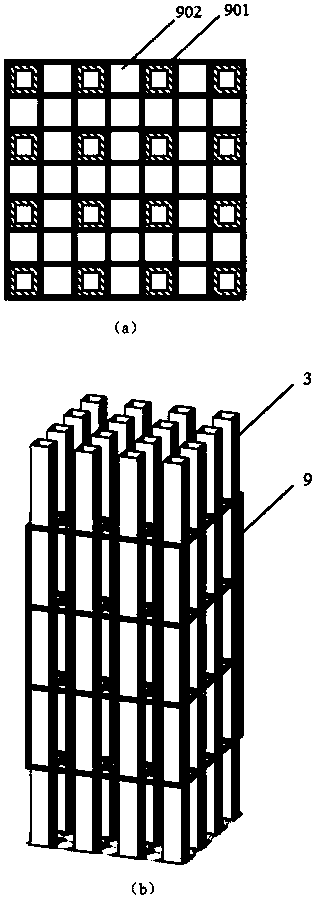

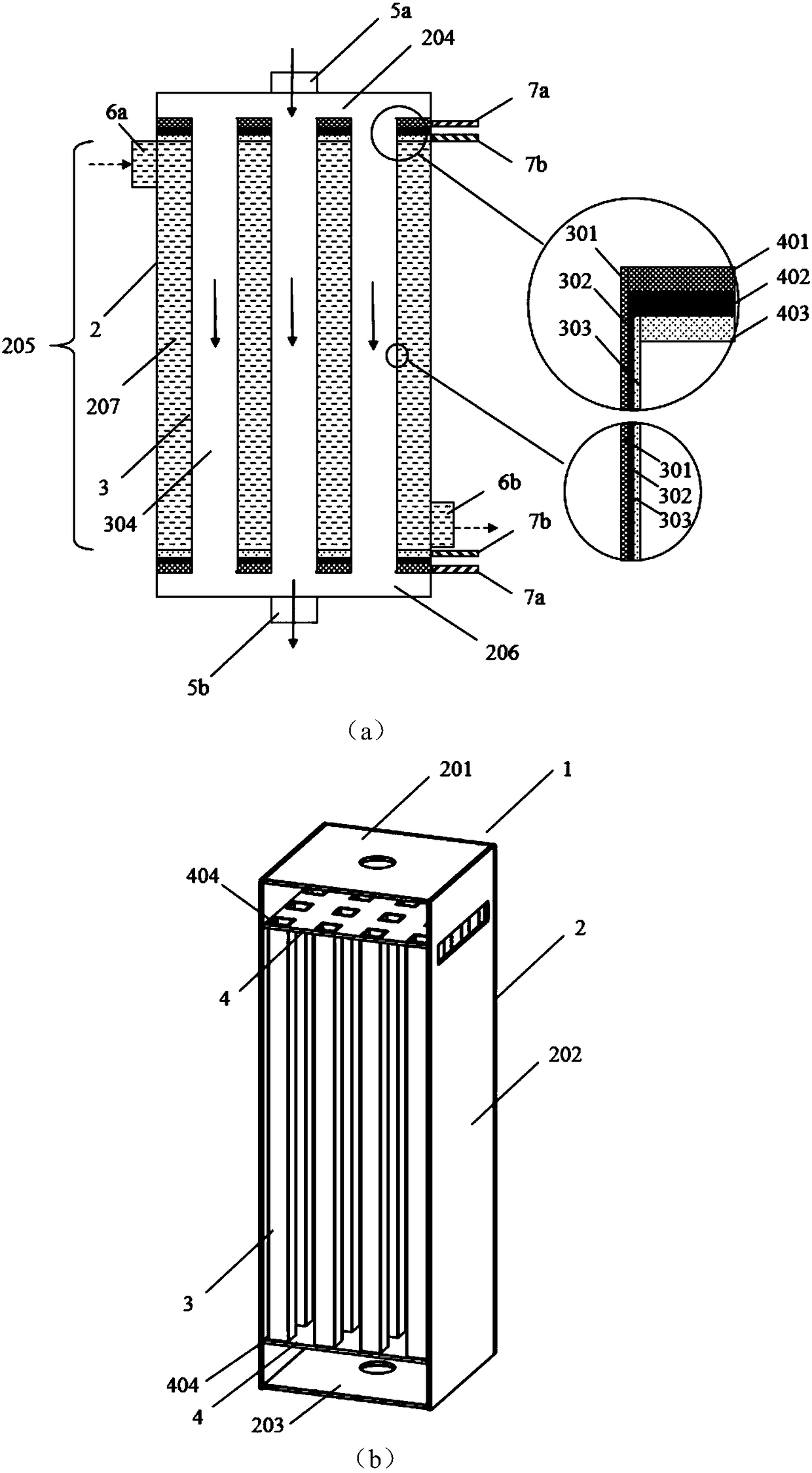

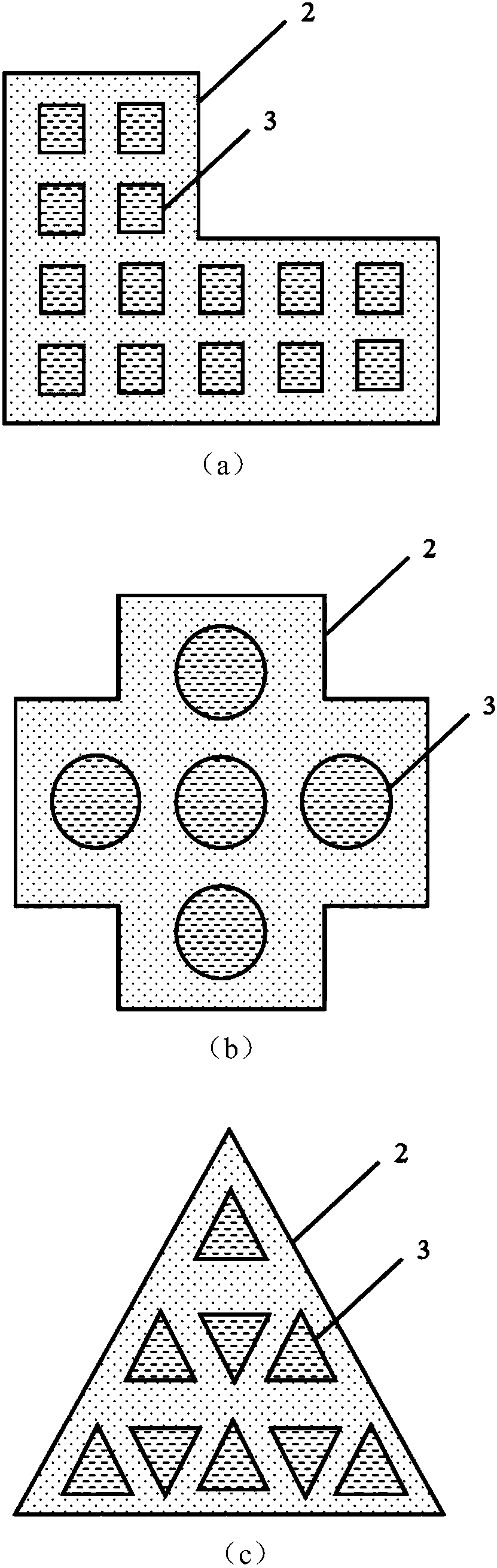

[0061] figure 1 is a schematic diagram of a tubular reactor according to the present invention, wherein, figure 1 (a) is the longitudinal section of tubular reactor and the schematic diagram of partial enlargement, figure 1 (b) is a three-dimensional schematic diagram of a tubular reactor. The tubular reactor 1 includes an outer tube 2, an inner tube 3, a composite collector plate 4, a first electrode slurry inlet 5a, a first electrode slurry outlet 5b, a second electrode slurry inlet 6a, and a second electrode slurry outlet 6b, the first tab 7a and the second tab 7b. The outer tube 2 includes a top 201 , a side wall 202 and a bottom 203 , the first electrode slurry inlet 5 a is set at the top 201 of the outer tube, and the first electrode slurry outlet 5 b is set at the bottom 203 of the outer tube. The upper part of the upper composite current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com