Chestnut and its storage method

A technology of chestnut and refrigerated temperature, which is applied in food science, edible seed preservation, food preservation, etc., can solve the problems that the processing time of chestnut deep-processing products is too concentrated, affects the quality of sugar-fried chestnuts on the market, and can't be listed in time for sugar-fried chestnuts. The effect of suppressing the decline of soluble sugar content, good market potential, optimal sweetness and mouthfeel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The storage method of the chestnut described in the present embodiment, the concrete steps are as follows:

[0034] (1) After the chestnut is harvested, it is stored in the storage warehouse, and the relative humidity is maintained above 90%;

[0035] (2) According to the planned delivery time, adjust the temperature, oxygen concentration, carbon dioxide concentration and nitrogen concentration of the storage warehouse;

[0036] (3) At the planned delivery time, the warehouse will be released and listed.

[0037] Wherein, the temperature, oxygen concentration, carbon dioxide concentration and nitrogen concentration of adjusting the storage warehouse described in step (2) correspond to different planned outgoing times, and the corresponding relationship is as follows:

[0038] (a) For the chestnuts that need to be released from the warehouse on the 6th to 14th day after the chestnut is harvested, the relative humidity is above 90%, and the temperature is 3 to 7°C, and 2...

Embodiment 2

[0044] The steps and storage conditions of Example 2 and Example 1 are basically the same, and the main difference between the two is that: for the chestnuts that need to be released from the warehouse on the 6th to 14th days after the chestnuts are harvested, they should be stored at room temperature and put in after harvesting. Set 20.9% O during library storage 2 +78.1%N 2 +0.03%CO 2 It can be stored at any time from the 6th to 14th day after the chestnut is harvested.

experiment example 1

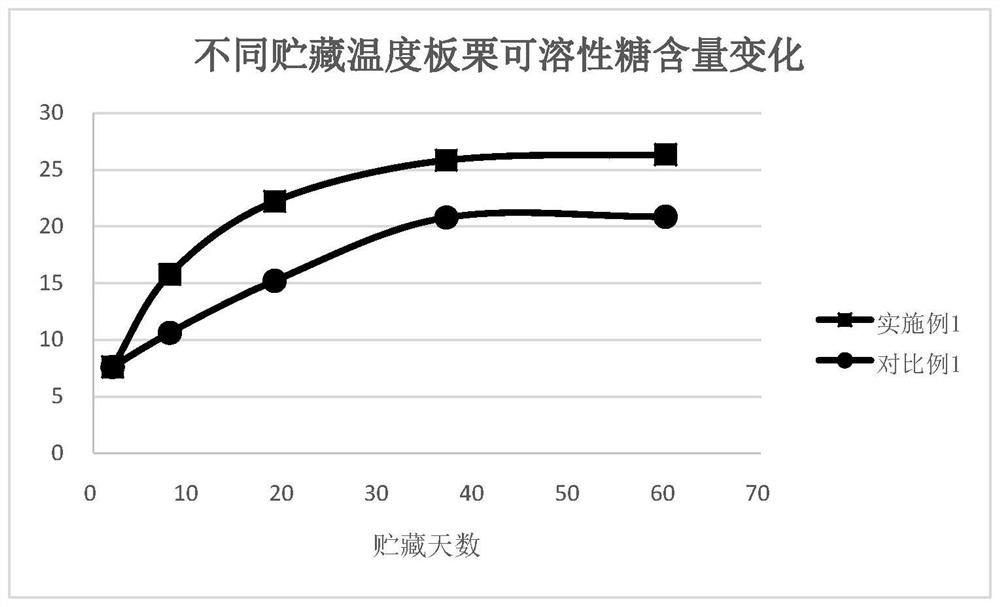

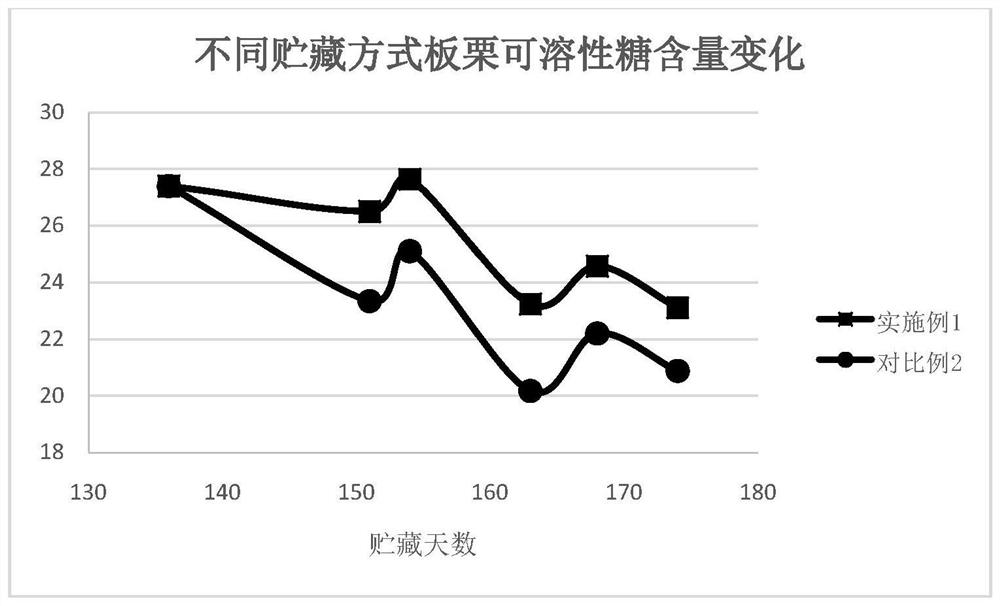

[0053] Experimental Example 1 Determination of soluble sugar content and test of the influence of storage conditions on soluble sugar content

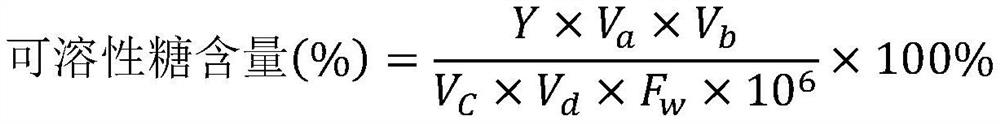

[0054] Because the soluble sugar content of chestnut directly affects the quality of fried food with sugar-fried chestnut, the higher the soluble sugar content, the sweeter the sugar-fried chestnut. The soluble sugar content of chestnuts after leaving the warehouse is determined by the following methods, as follows:

[0055] 1. Make a glucose standard curve

[0056] Glucose standard solution: Weigh 0.11g of glucose monohydrate, transfer all to a 1000ml volumetric flask, and prepare a 100μg / ml glucose standard solution for later use.

[0057] Anthrone reagent: Weigh 0.2g of anthrone, transfer all of it into a beaker, dissolve in 100ml of concentrated sulfuric acid to prepare 2g / L of anthrone reagent, prepare it for temporary use, and store it in the dark. Take 7 large test tubes and prepare a series of glucose solutions with different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com