Frameless wall-hung mirror and manufacturing technology thereof

A production process and technology for glass mirrors, applied in mirrors, picture frames, other household appliances, etc., can solve the problems of exposed metal aluminum layer exposed to moisture and oxidation, poor service life and usability, and glass mirrors susceptible to moisture and oxidation. The effect of widening the scope, expanding the demand for changes in decorative shapes, and increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

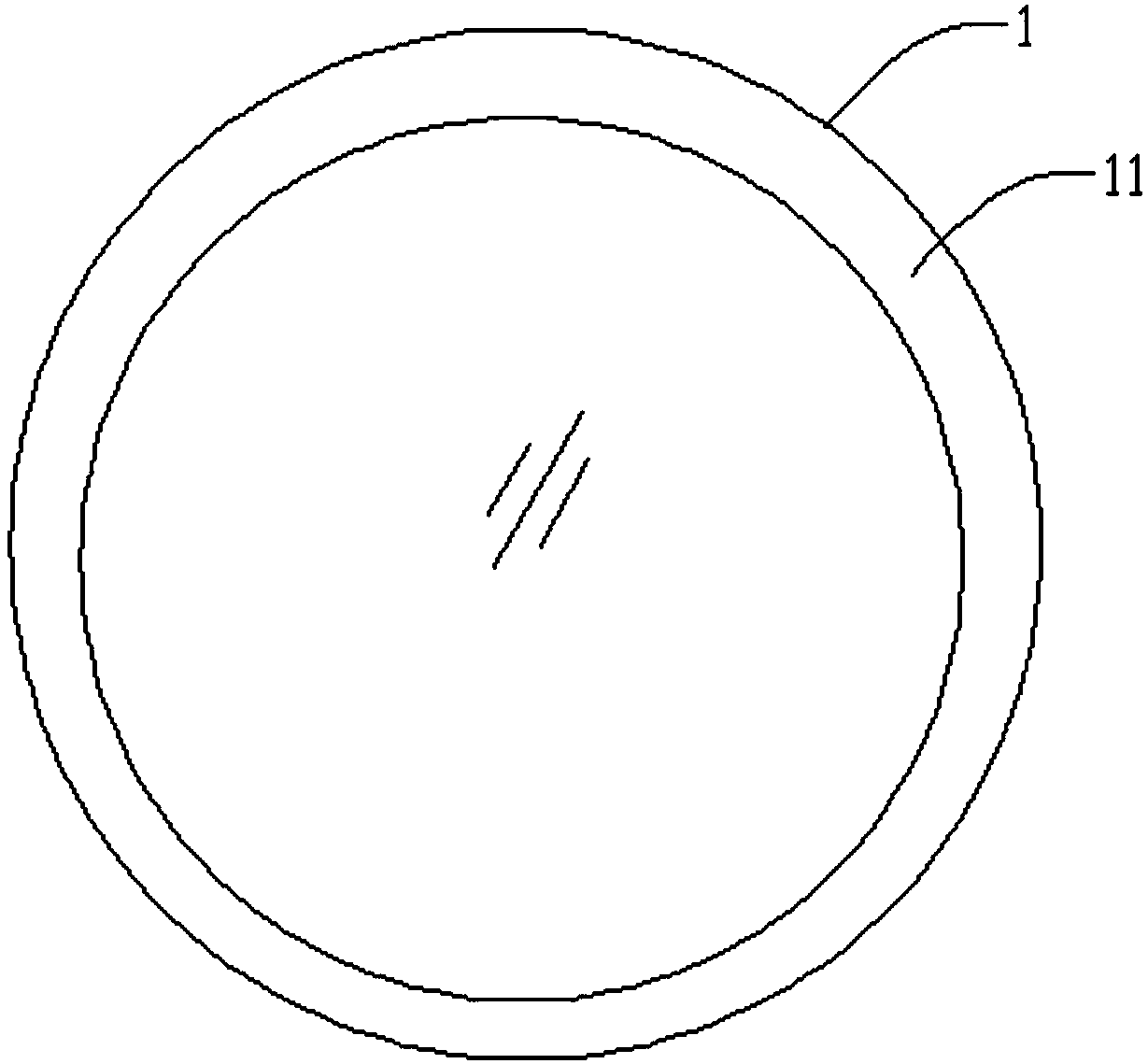

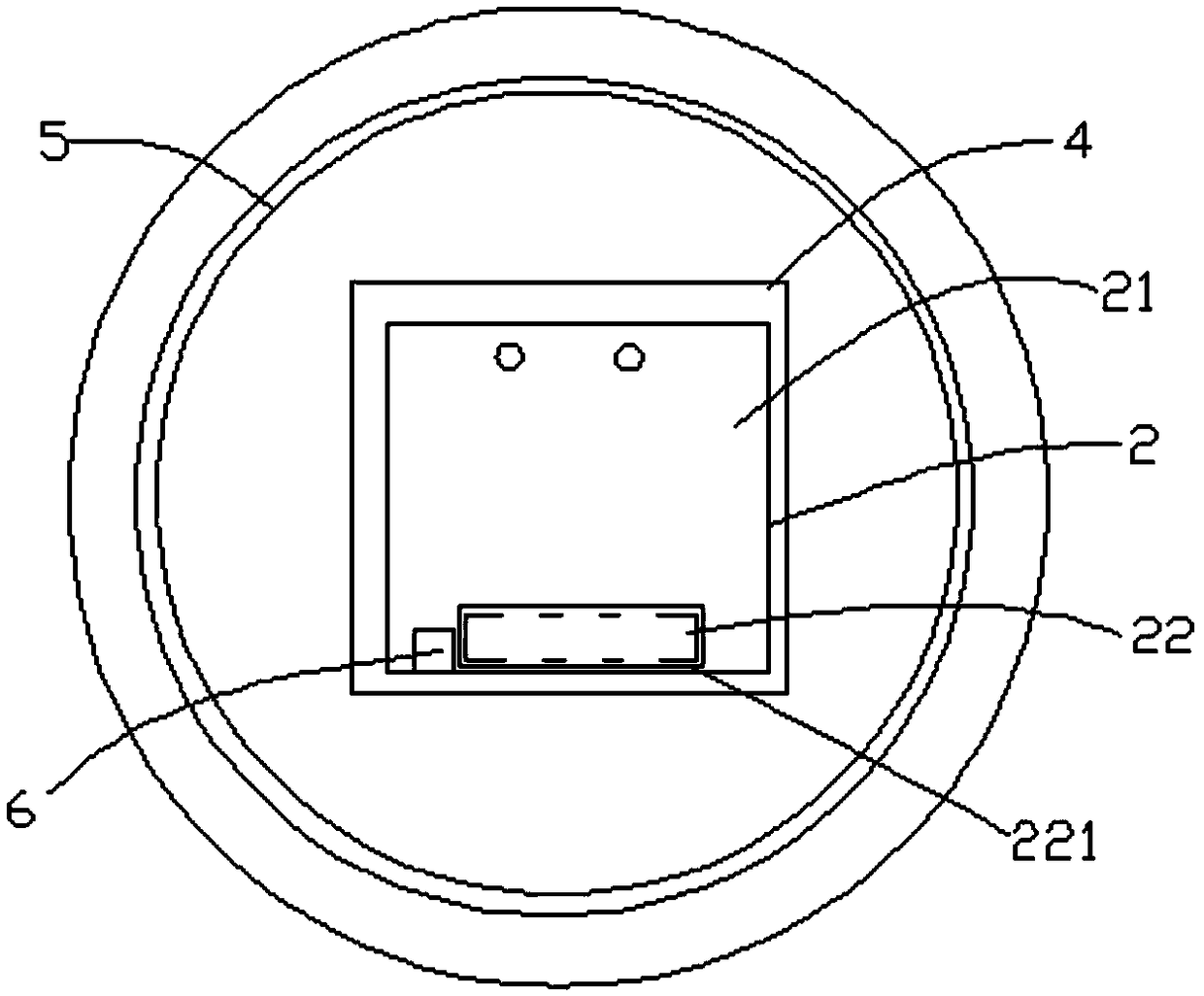

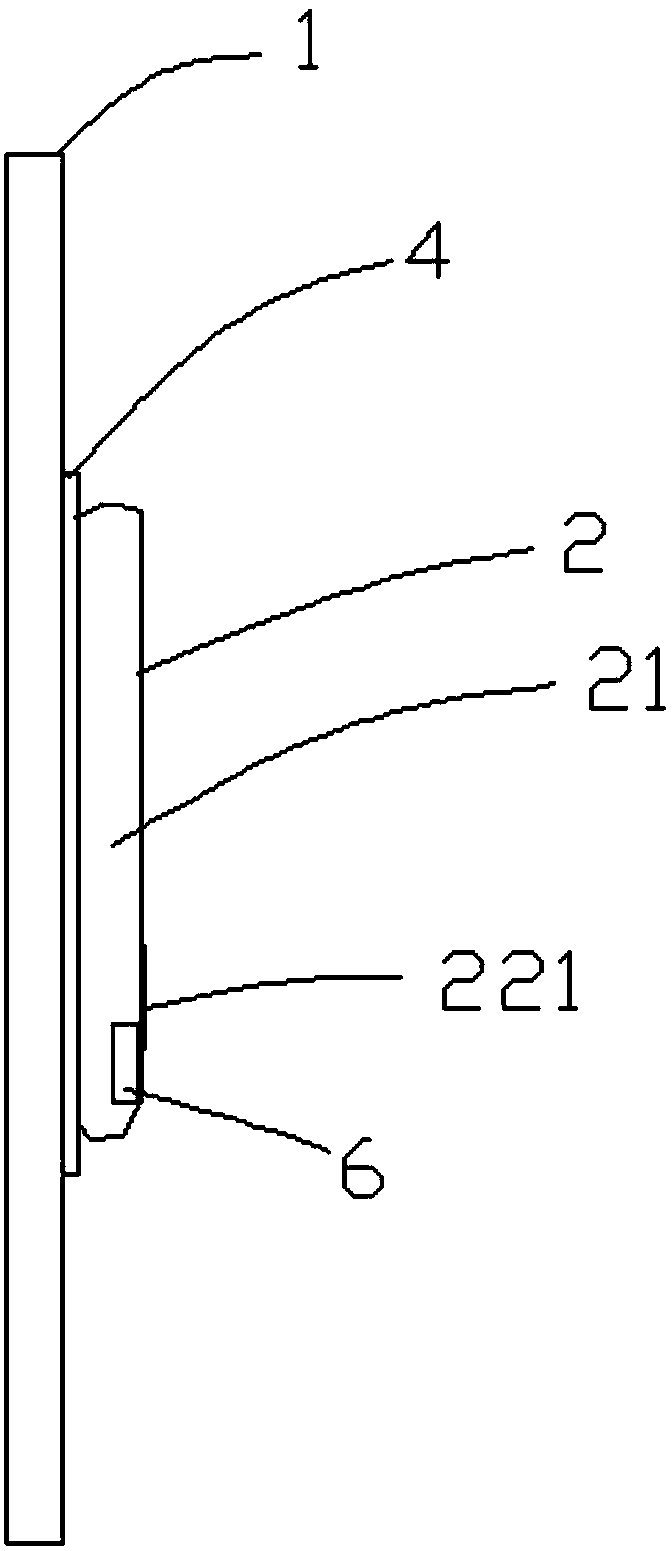

[0029] A frameless hanging mirror, comprising a glass lens 1, the glass lens 1 is a frameless glass lens, the sides of the glass lens 1 are round and smooth, and the sides and back of the glass lens 1 are covered with a layer of epoxy resin layer 12 , the middle of the back is bonded with a layer of toluene-free low-temperature hot-melt film 4 in turn, and the other side of the toluene-free low-temperature hot-melt film 4 is bonded with a hanging shell 2. The area of the toluene-free low-temperature hot-melt film 4 and the hanging shell 2 Respectively smaller than the glass lens 1, the hanging shell 2 is a kind of ABS engineering plastics, which is outwardly convex, and is bonded with the toluene-free low-temperature hot-melt film 4 to form a cavity 21, and the hanging shell 2 is provided with a hanging Hole 3. In the drawings, the glass lens 1 is circular, but in actual use, the glass lens 1 can be any shape of lens.

[0030] The surface of the glass lens 1 is provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com