Full-automatic all-in-one machine for rolling moxa

A fully automatic, all-in-one technology, applied in the direction of heating/cooling reflection point instruments, etc., can solve the problems of unfavorable installation in limited production space, the demand of the market that is easy to generate dust, and the impact of dust on the health of operators, and achieves a beautiful appearance. , Effective use of space, the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

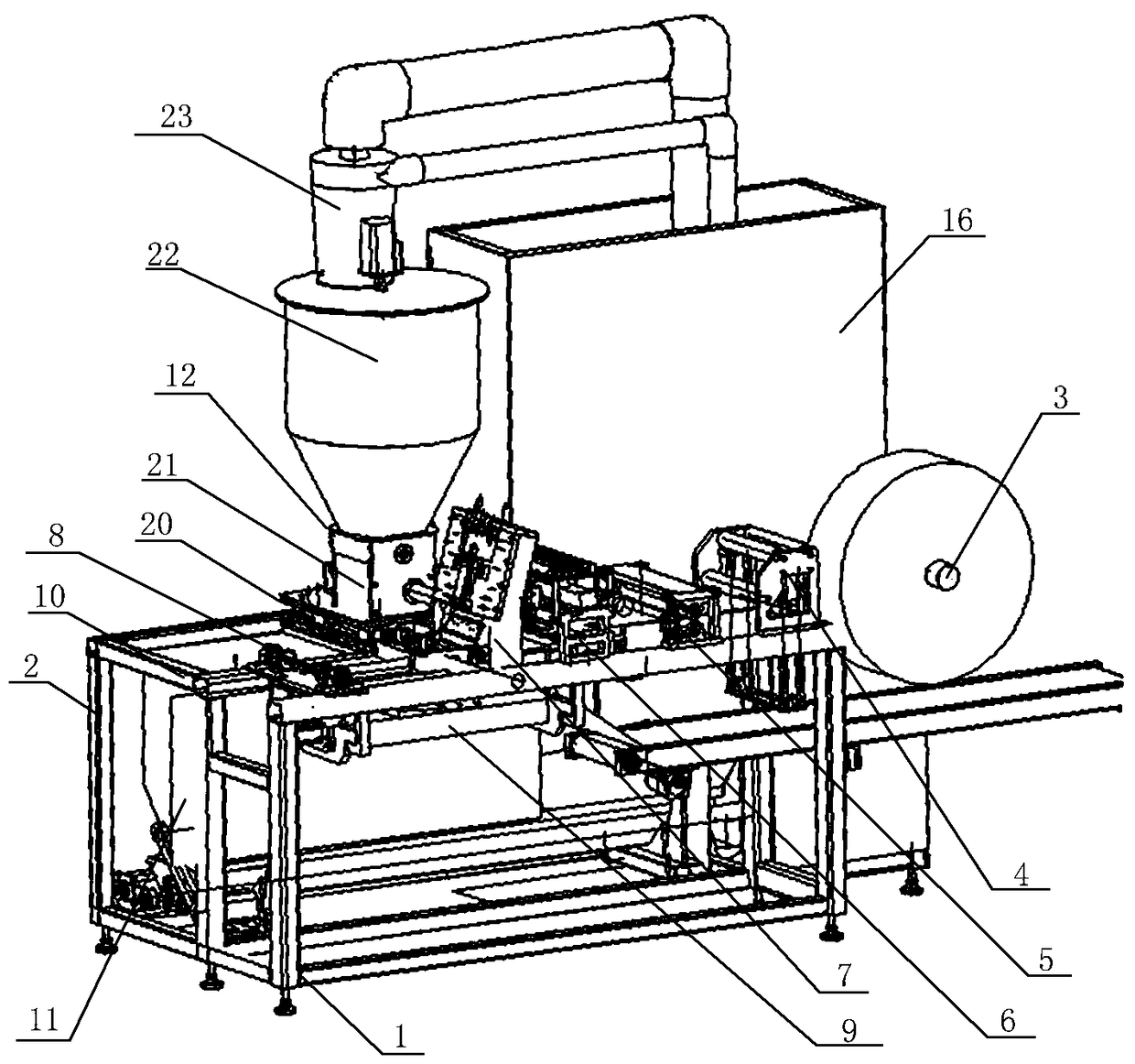

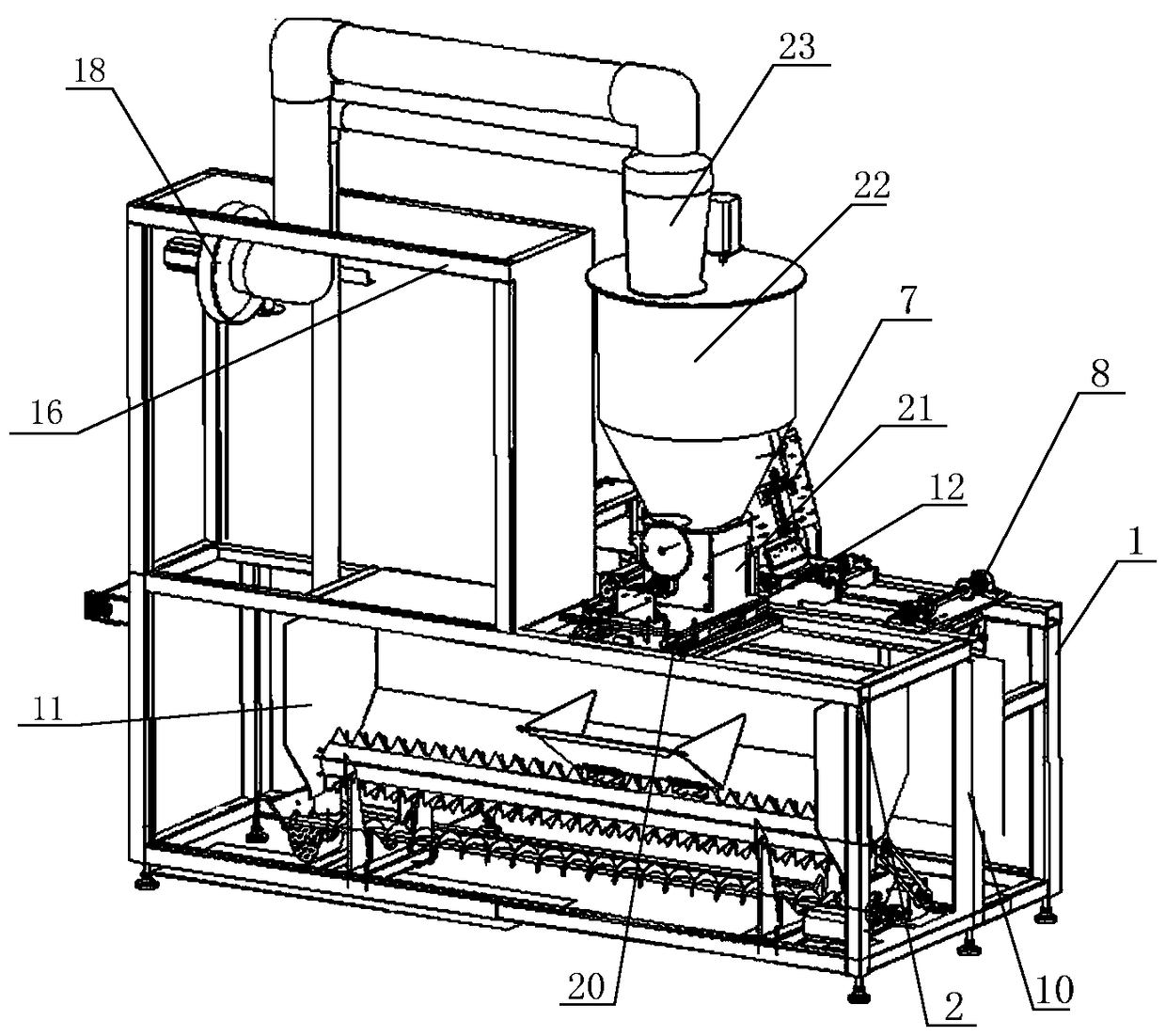

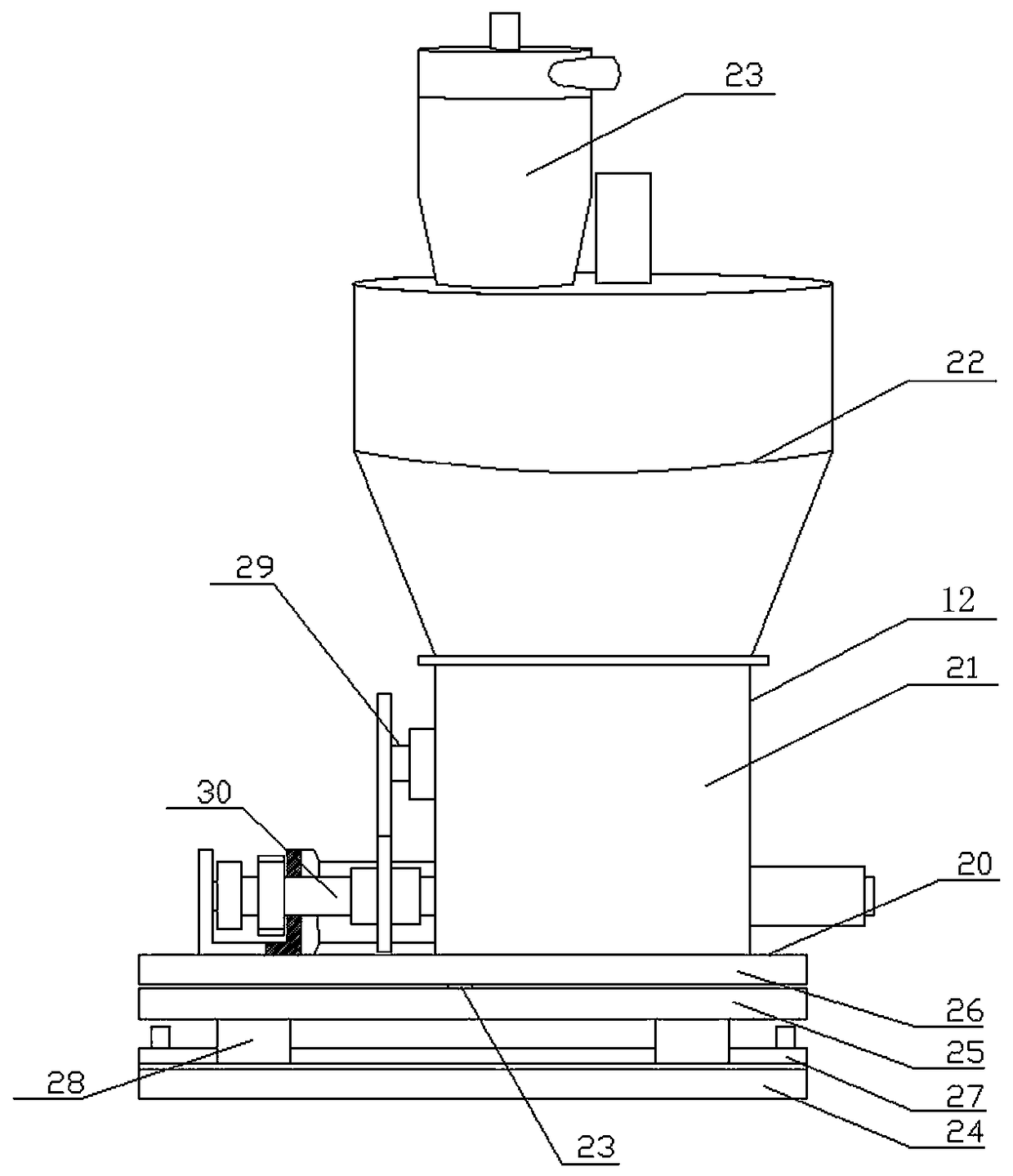

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-4 Shown: a full-automatic moxa rolling machine, comprising a winding machine 1 and a moxa feeding mechanism 2, one end of the frame of the winding machine 1 is provided with a paper roll holder 3, and the top surface of the frame of the winding machine 1 is One end of the paper roll stand 3 is provided with a paper passing roller 4, a paper feeding roller 5, a gluing mechanism 6, a pounding mechanism 7 and a cloth rolling mechanism 8 in sequence, and the bottom surface of the winding machine 1 is provided with a stamping mechanism below the frame. Winding mechanism, the bottom of described winding mechanism is provided with slide plate 9 and conveyer belt for guiding moxa stick, one side of described winding machine 1 is provided with moxa feeding mechanism 2, and described moxa feeding mechanism 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com