Two-stage mechanical sand recycling device

A recovery device and machine-made sand technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of difficult layout and installation, low recovery efficiency, increased energy consumption, etc., and achieve installation Convenience, high recycling efficiency, and increased working resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The core of the invention is to provide a two-stage machine-made sand recovery device.

[0021] Below in conjunction with accompanying drawing, content of the present invention will be further described:

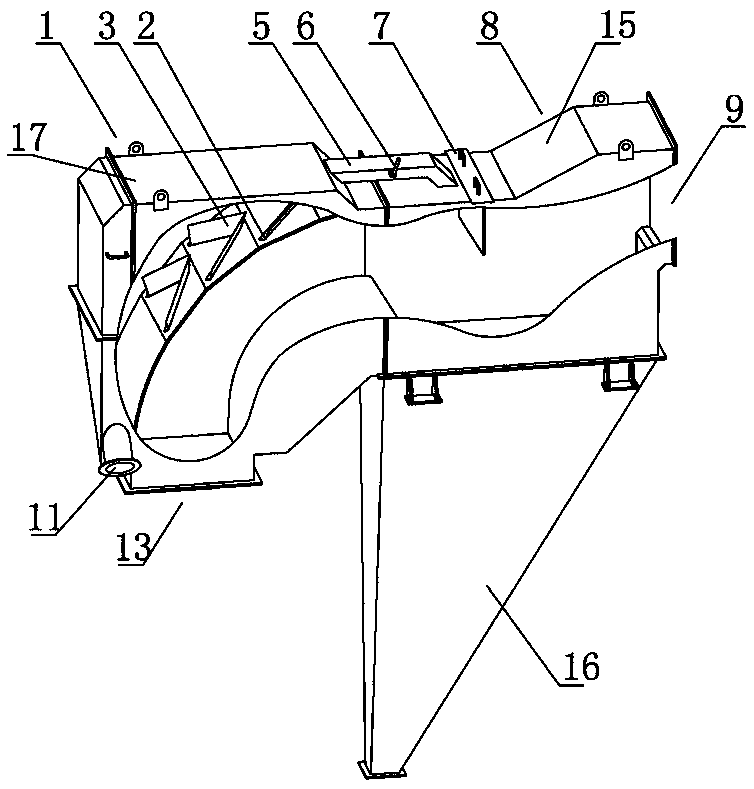

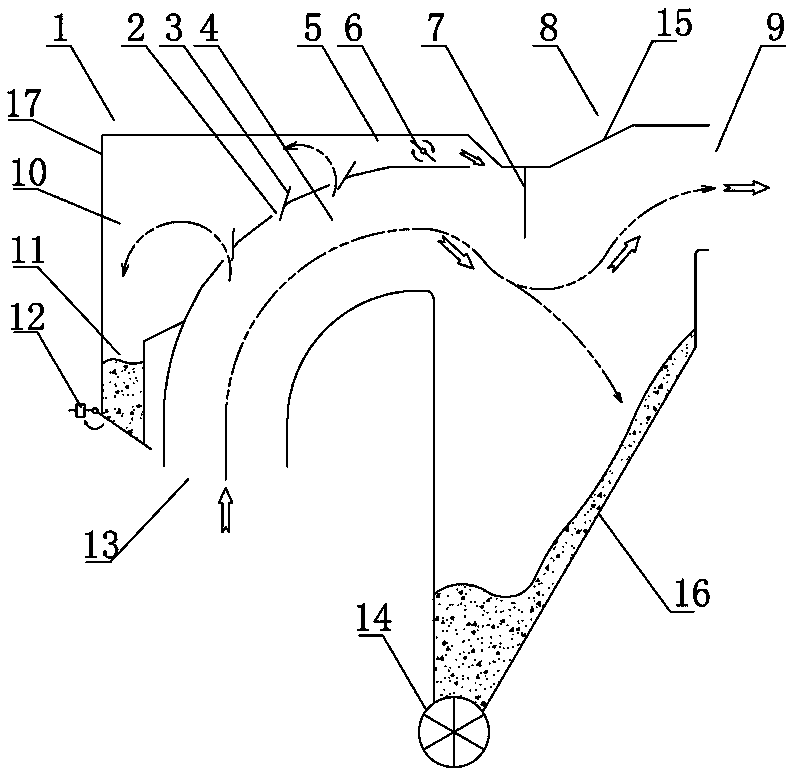

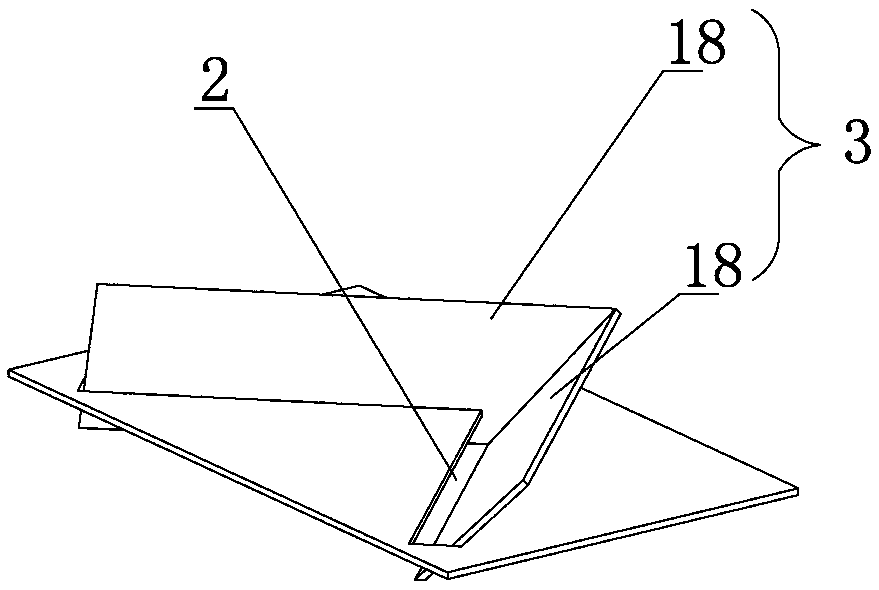

[0022] A two-stage machine-made sand recovery device, such as figure 1 , 3 As shown, it includes the coarse sand collector 1 and the inertial dust collector 8 which are connected in series in sequence, and the air outlet of the coarse sand collector 1 is directly connected to the air inlet of the inertial dust collector 8; wherein the coarse sand collector 1 includes a 90° bend Pipe air duct 4 and cover are arranged on the dust collection cover 17 above 90 ° elbow air duct 4, the side wall of dust collection cover 17 and the side wall of 90 ° elbow air duct 4 are fitted and sealed, and dust collection cover 17 and The collecting bin 10 is formed between the side walls facing upward of the 90° elbow air duct 4; Set straight downward, the air outlet of the 90° elbow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com