Forging, pressing, stamping and quenching integrated molding process and equipment

A molding process and integrated technology, applied in molding tools, metal processing equipment, manufacturing tools, etc., can solve the problems of easy brittle cracking, low temperature resistance and durability, and reduced workpiece hardness, achieve uniform pressure, increase temperature resistance, The effect of small deformation of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

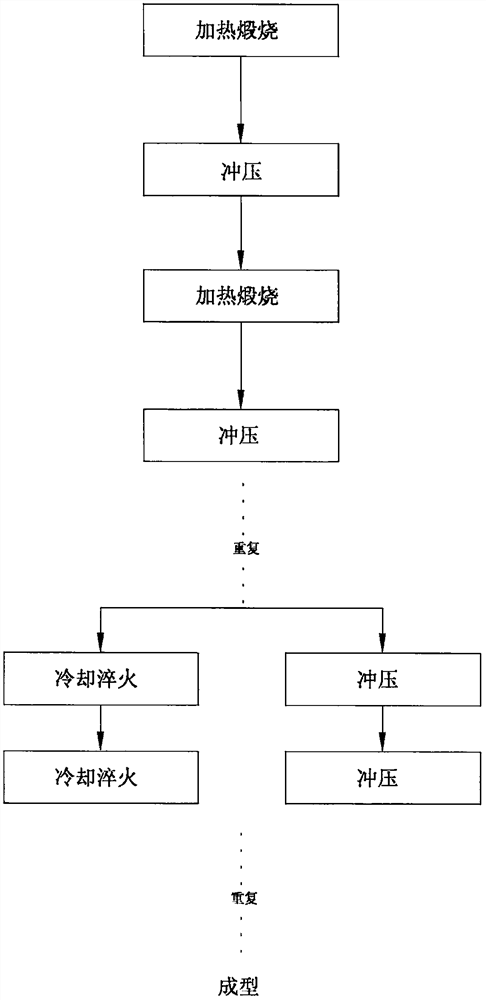

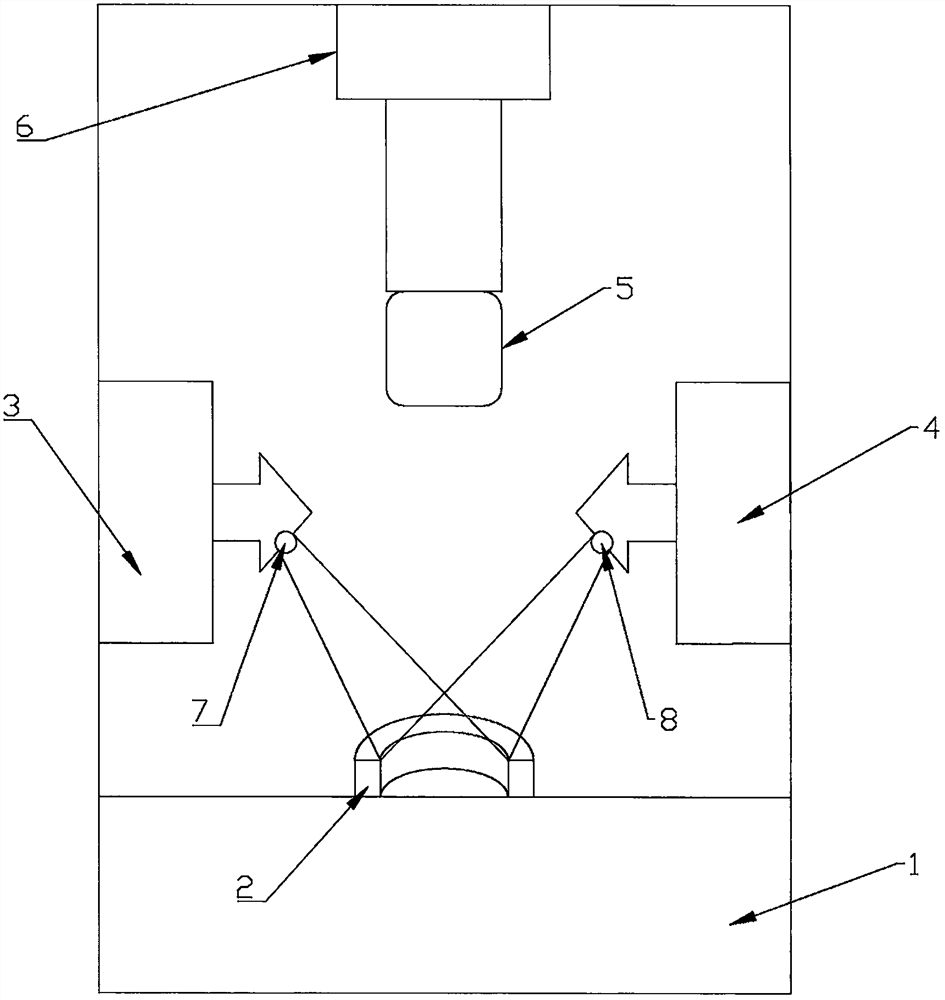

[0026] An integral molding process of forging, pressing, stamping and quenching, the steps of which are:

[0027] (1) Place the workpiece with a thickness of 20cm in the forming mold of the punching machine, and the laser will heat and calcinate the workpiece, and the heating temperature is 50°C lower than the melting point of the workpiece material;

[0028] (2) After the heating is completed, stop the heating device and use an area of 100cm 2 The punch punches the workpiece, and the stamping standard time is T 1 ;

[0029] (3) After the stamping is completed, the laser is controlled to heat and calcine the workpiece again, and the heating and calcination and stamping are carried out alternately until the workpiece is punched and formed in the forming die, and the punching time required for punching the workpiece is T=2×1×T 1 = 2T 1 ;

[0030] (4) Start the water-cooling device to cool and quench the formed workpiece, and at the same time control the punch to stamp the ...

Embodiment 2

[0033] An integral molding process of forging, pressing, stamping and quenching, the steps of which are:

[0034] (1) A workpiece with a thickness of 10 cm is placed in the molding die on the punching machine, and the electric heater heats and calcines the workpiece, and the heating temperature is 100°C lower than the melting point of the workpiece material;

[0035] (2) After the heating is completed, stop the heating device and use an area of 100cm 2 The punch punches the workpiece, and the stamping standard time is T 1 ;

[0036] (3) After the stamping is completed, the laser is controlled to heat and calcine the workpiece again, and the heating and calcination and stamping are carried out alternately until the workpiece is punched through the forming die, and the stamping time required for heating and punching through the workpiece is T=1×1×T 1 =T 1 ;

[0037] (4) Start the water-cooling device to cool and quench the formed workpiece, and at the same time control the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com