Automatic fastener dismounting system and method based on machine vision

A technology of automatic disassembly and machine vision, applied in manipulators, program-controlled manipulators, metal processing, etc., can solve the problems of poor safety, low efficiency, and high disassembly costs for dismantling workers, and achieve improved operation safety, convenient operation, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

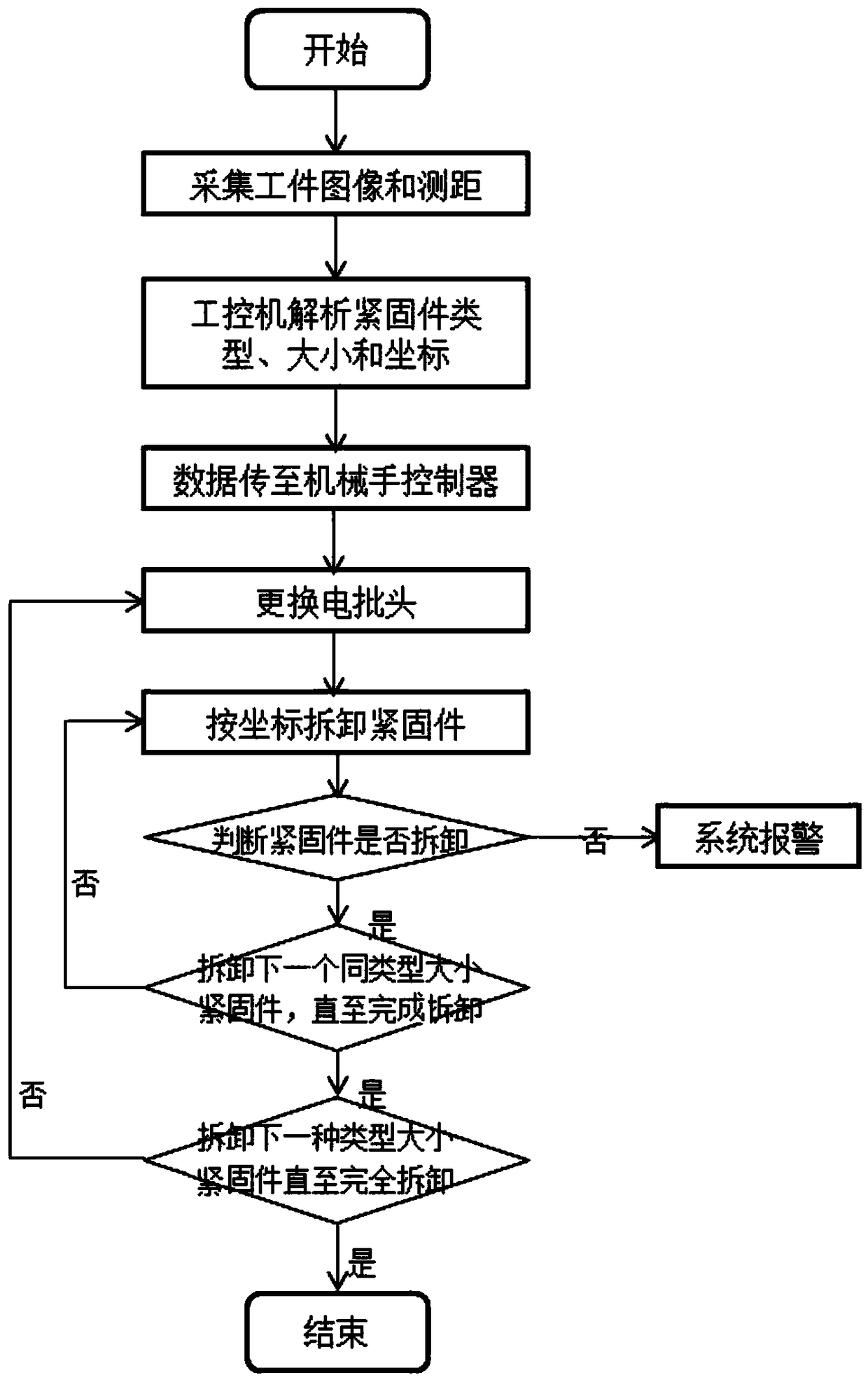

[0032] The actual operation method is as follows:

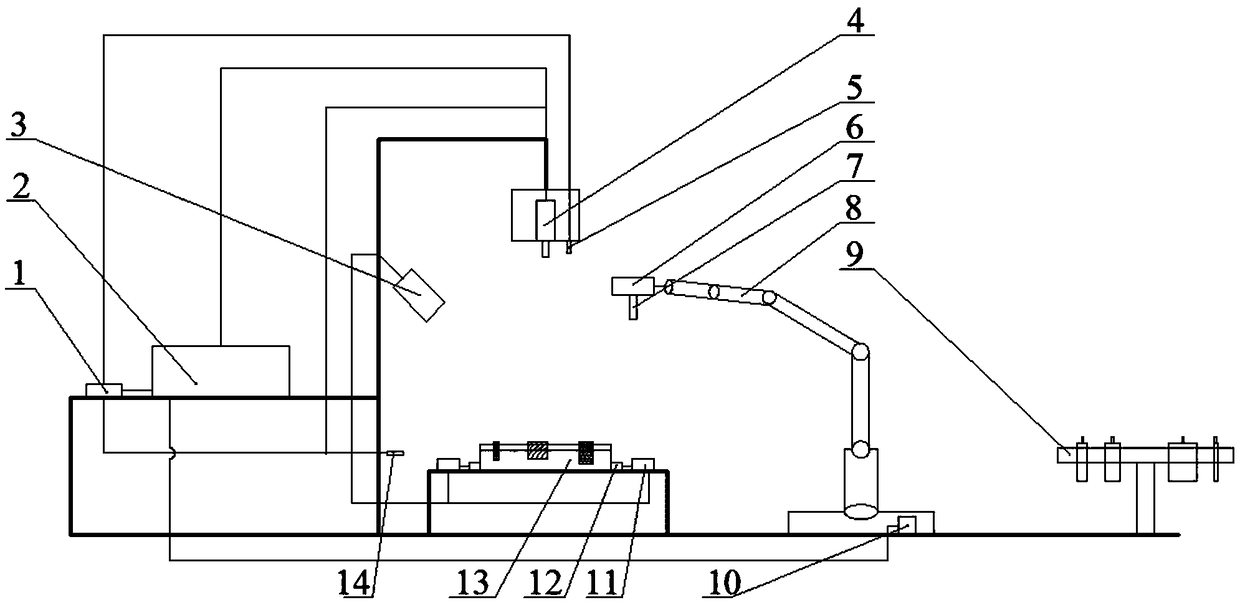

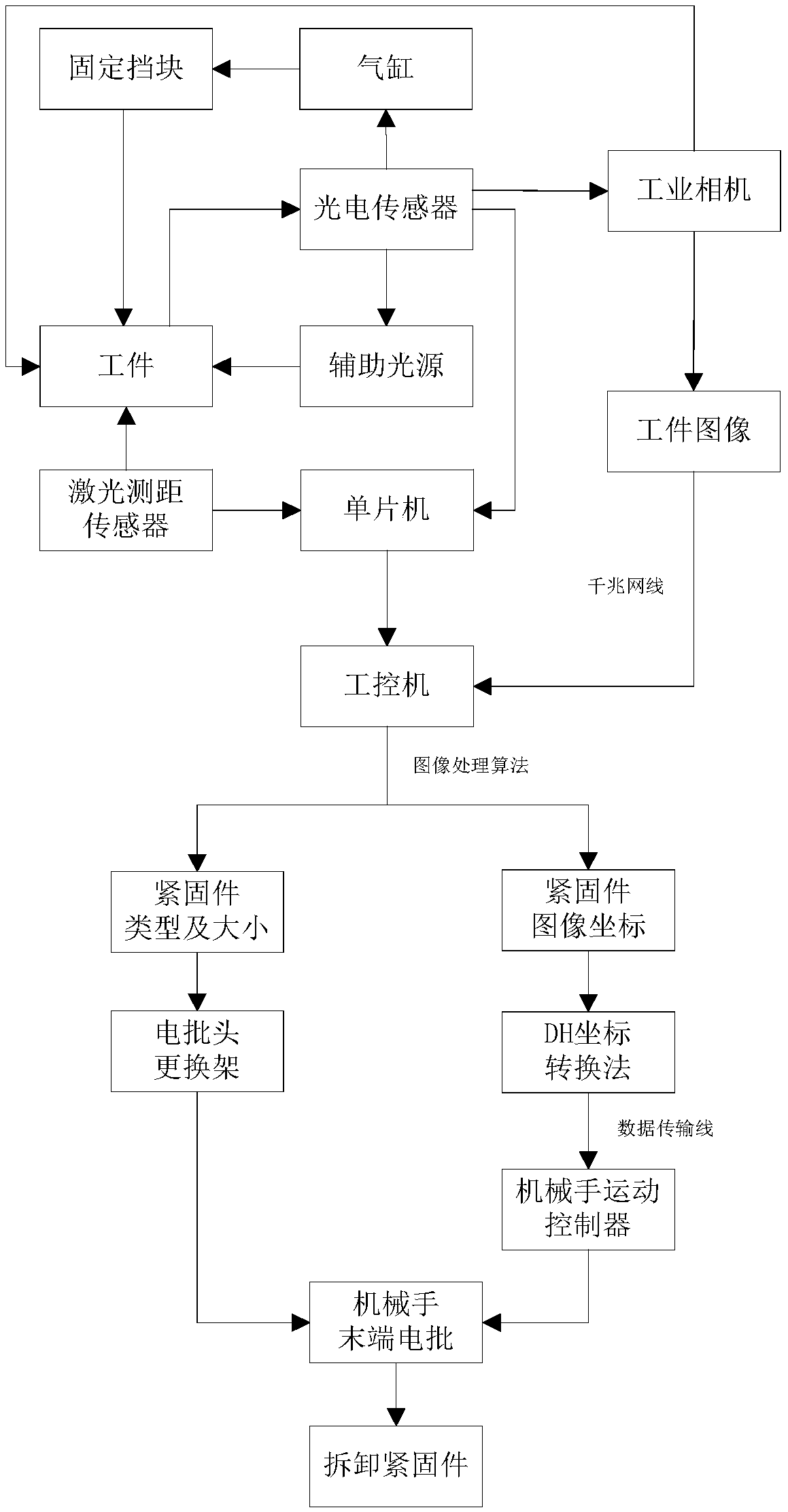

[0033] The photoelectric sensor 14 detects the arrival of the workpiece 13, and the cylinder 11 detects the signal of the photoelectric sensor 14 and moves the fixed stop 12 to fix the workpiece 13. The photoelectric sensor 14 automatically triggers the auxiliary light source 3, triggers the industrial camera 4 to capture the image of the workpiece 13, and the single-chip 1 detects After the signal from the photoelectric sensor 14 is reached, the laser ranging sensor 5 is automatically turned on to measure the distance between the industrial camera 4 and the plane of the workpiece 13. The image of the workpiece is transmitted to the industrial computer 2 through the gigabit network cable, and the industrial computer 2 uses the image processing algorithm to identify the tightening of the workpiece 13 The type and size of the fastener, the image coordinates of the fastener, the industrial computer 2 transmits the fastener type, siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com