Positioning and assembling method and device of part and composite material skeleton skin structure

A composite material and assembly method technology, which is applied in the field of resin-based structural composite material molding, can solve problems such as the inability to determine the installation reference and the inability to guarantee the accuracy of the shape and surface, so as to ensure the requirements of the aerodynamic shape, improve the quality of interface bonding and the accuracy of the shape and size , The effect of accurate positioning position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

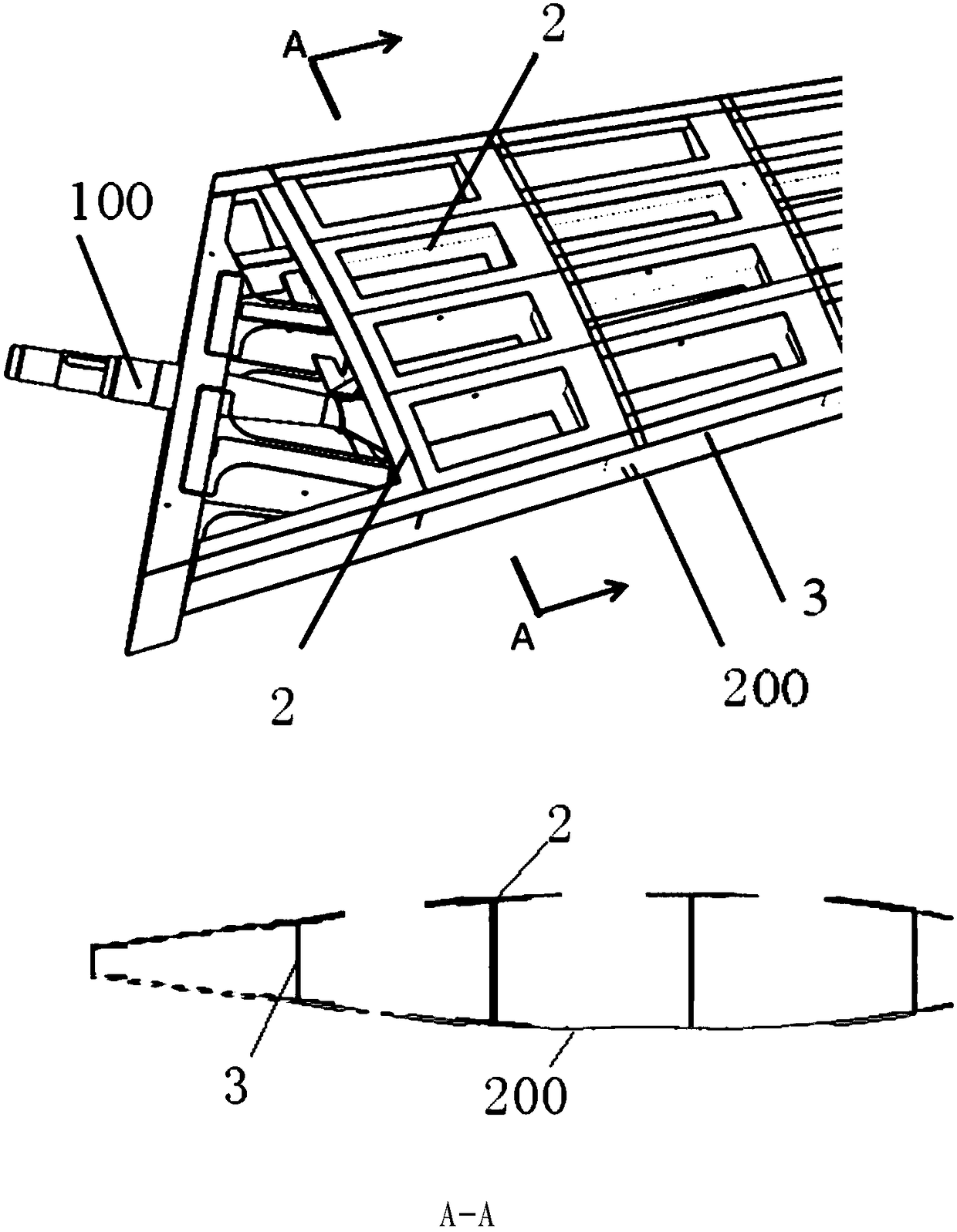

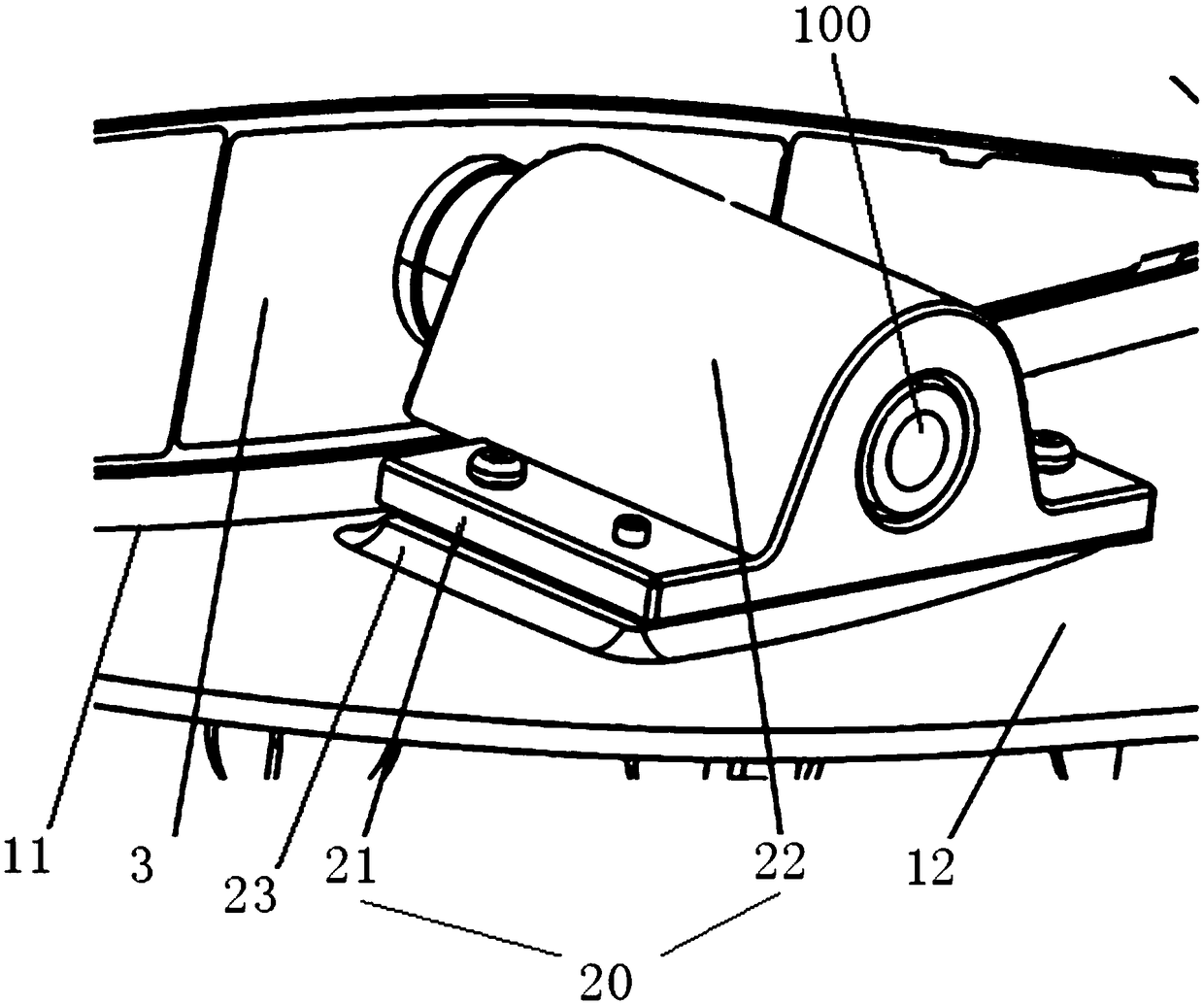

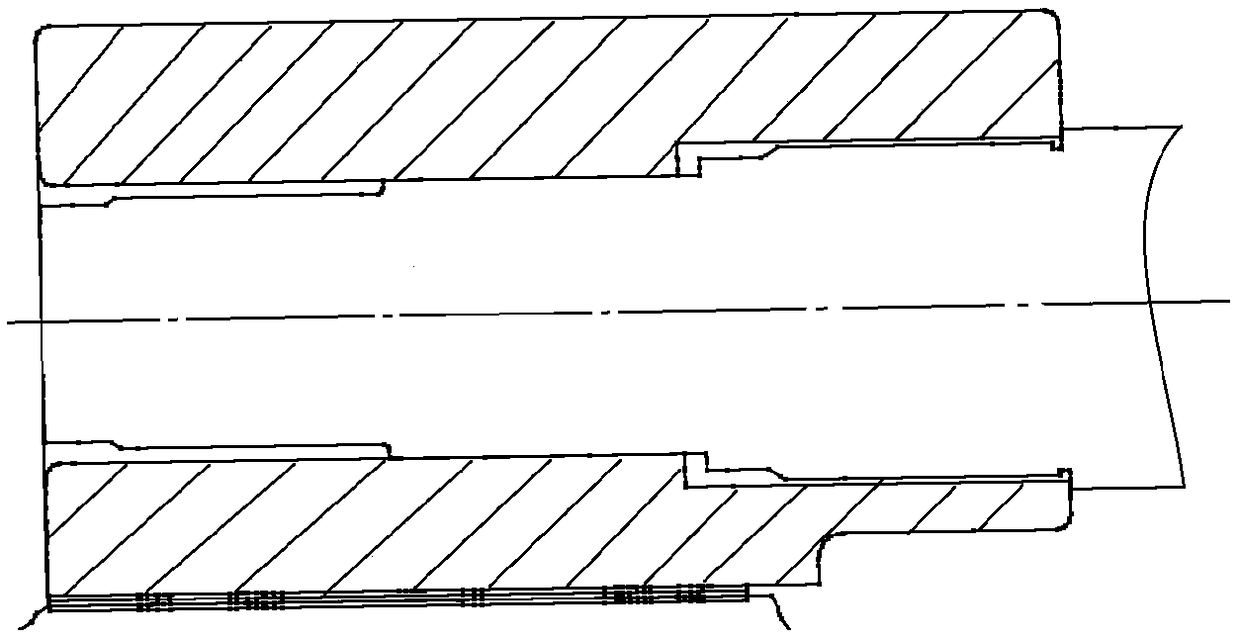

[0065] like figure 1 As shown, the present embodiment provides a composite skeleton skin structure for aircraft empennage, comprising an integral skeleton, a metal rudder shaft and a lower skin 200, and the skeleton structure consists of an upper frame, a lower frame, and a plurality of groups of different heights. Board 3, wherein the upper frame is surrounded by a plurality of first frame bars 1 to form a multi-grid structure, the lower frame is surrounded by a plurality of second frame bars 2 to form a multi-grid structure, the first frame bars 1 and the second frame bars 2 One-to-one correspondence, a vertical plate 3 is provided between the corresponding first frame bar 1 and the second frame bar 2, and forms a structure with an I-shaped vertical section. The upper surface of the upper frame and the lower surface of the lower frame are both A double-curvature surface, correspondingly, the lower skin 200 is also a double-curvature surface. The skeleton skin structure is ma...

Embodiment 2

[0083] like Figure 6 As shown, the present embodiment provides a composite skeleton skin structure for aircraft wings, including an integral skeleton and a lower skin 200, and the skeleton structure is composed of an upper frame, a lower frame and multiple sets of vertical plates 3 with different heights , wherein the upper frame is surrounded by a plurality of first frame bars 1 to form a multi-grid structure, and the lower frame is surrounded by a plurality of second frame bars 2 to form a multi-grid structure. The first frame bars 1 and the second frame bars 2 correspond one-to-one , a vertical plate 3 is arranged between the corresponding first frame bar 1 and the second frame bar 2, and forms a structure with an I-shaped vertical section, and the upper surface of the upper frame and the lower surface of the lower frame are double-curvature surfaces Correspondingly, the lower skin 200 is also a double-curvature surface, and the skeleton skin structure is made of carbon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com