Modular packing type storage battery storage device for UPS power van

A storage device and battery storage technology, used in motor vehicles, goods transport vehicles, transportation and packaging, etc., can solve the problems of raising the center of gravity of the whole vehicle, scalability, poor redundancy, and height impact, etc. The height of the center of gravity is beneficial to the driving stability and the effect of reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings:

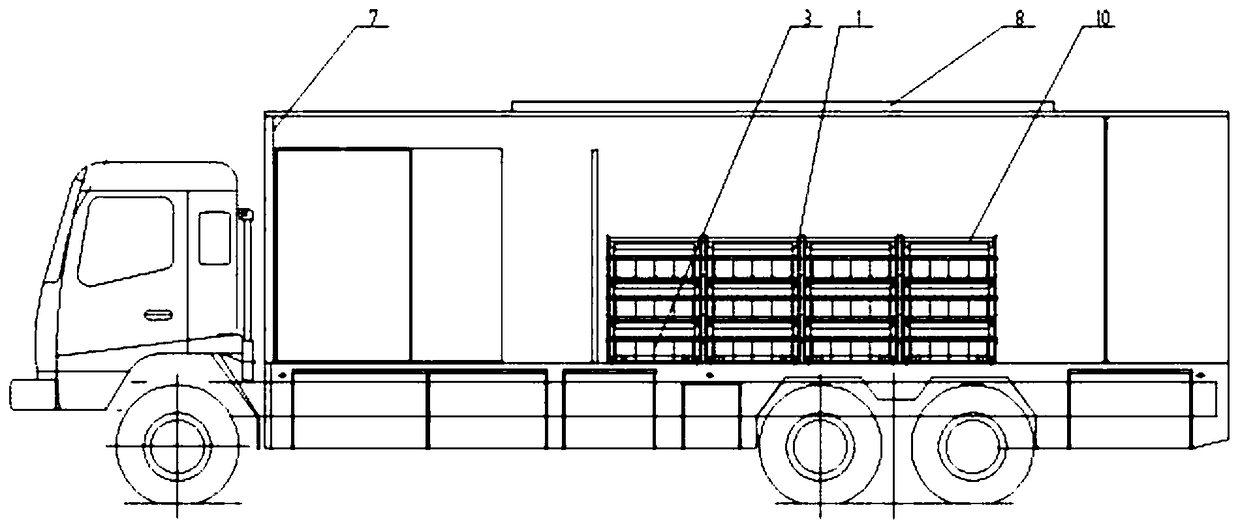

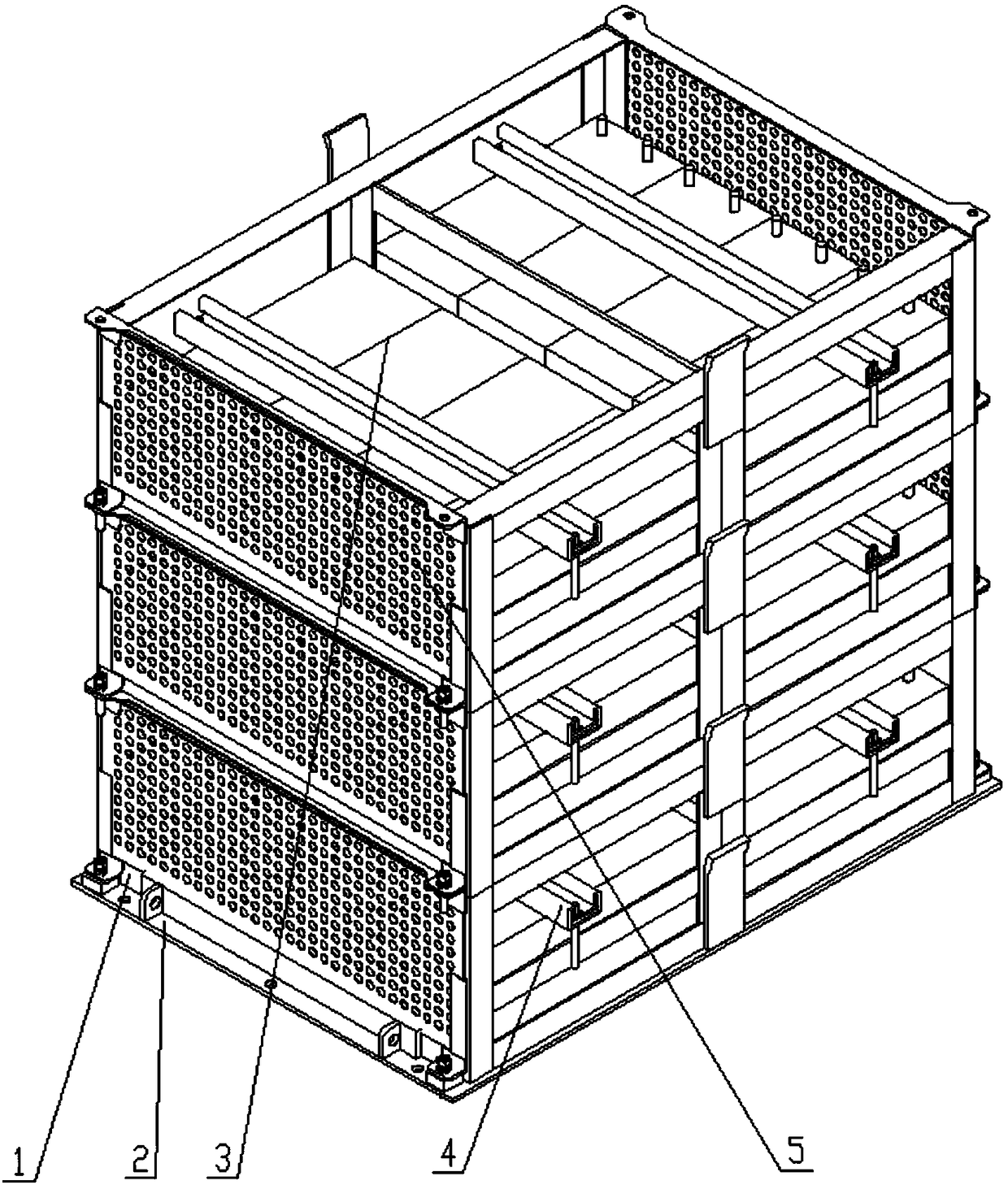

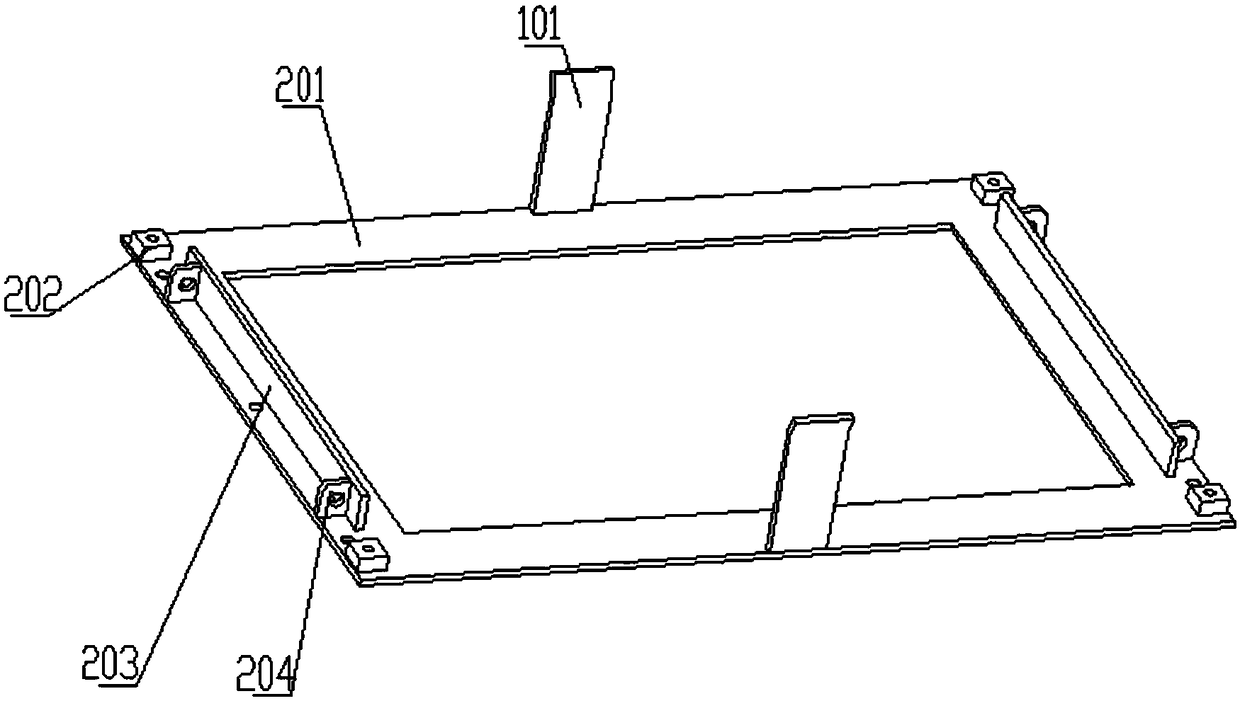

[0037] The module sub-assembly type battery storage device of UPS power vehicle of the present invention, such as figure 1 with 2 As shown, it includes a battery storage unit 1, a base unit 2, a compression unit 4, a protection unit 5, a shock absorption unit 9 and a reinforcement unit 10 (the reinforcement unit is a cover plate provided on the uppermost layer), and the bottom battery storage unit 1 Installed on the base unit 2. The battery storage unit 1 can be stacked in layers and installed upwards. Each layer of the battery storage unit 1 is connected up and down by a recessed limit structure and bolts on the top of each layer. The upper battery is stored When the unit 1 is placed on the lower battery storage unit 1, the sliding groove baffle 101 in the front and rear direction slides downwards into the concave limit structure. A prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com