High-speed train unit axle box built-in power bogie and rail vehicle with bogie

A high-speed EMU and power bogie technology, applied in the field of rail vehicles, can solve the problems of reducing the overall size of the bogie, the small limit of the EMU, and achieve the effect of omitting space, occupying less lateral space, and reducing lateral occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

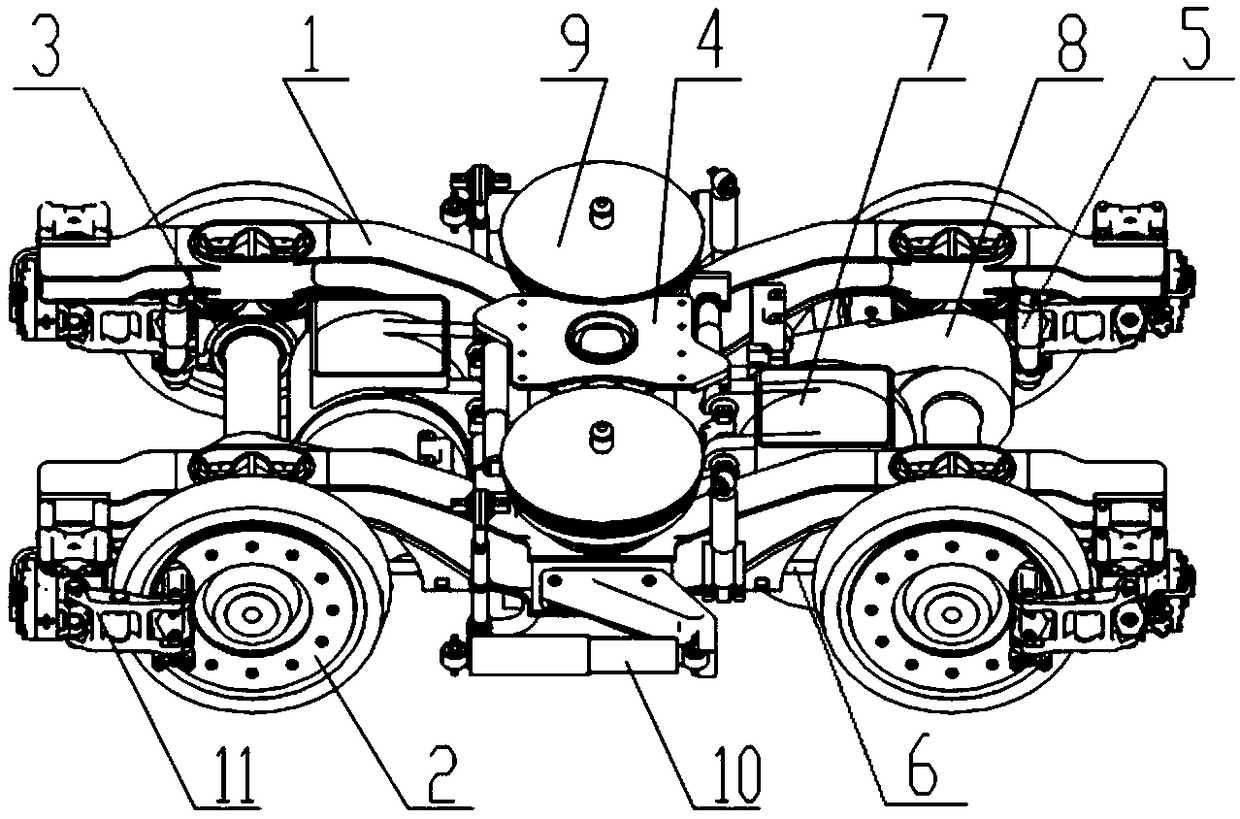

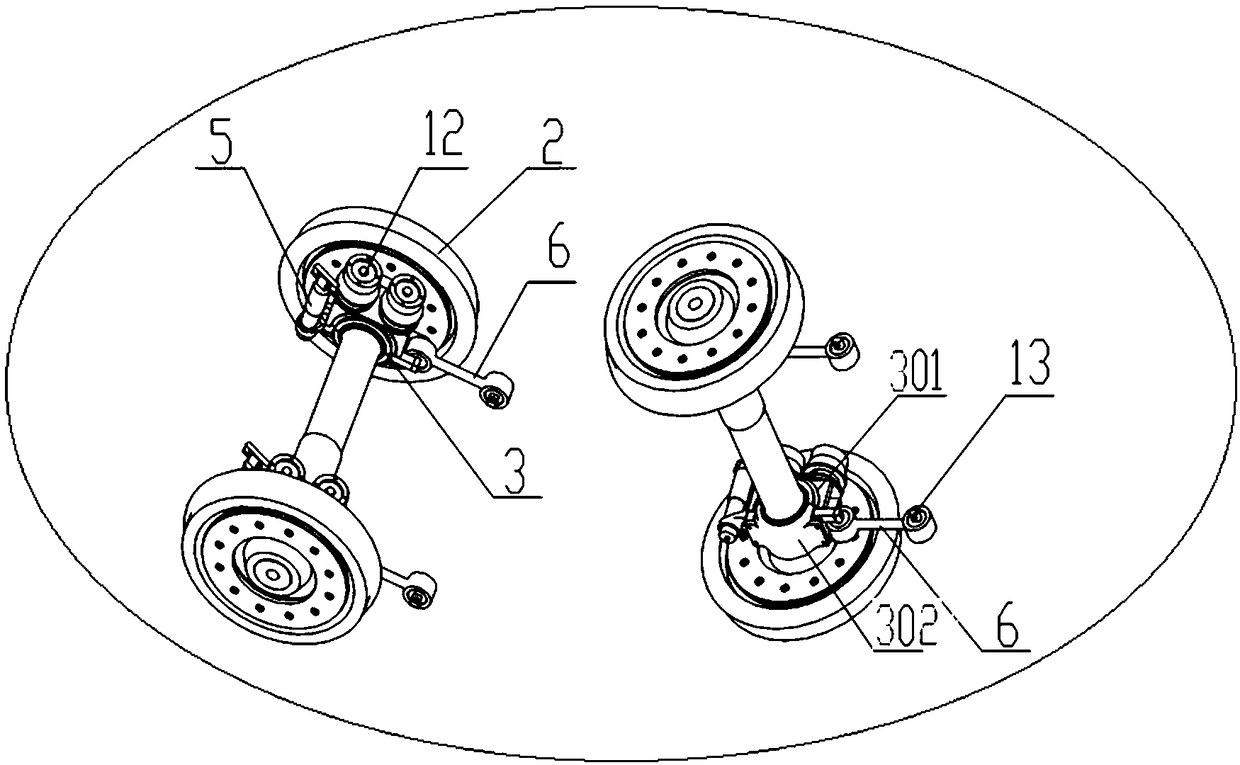

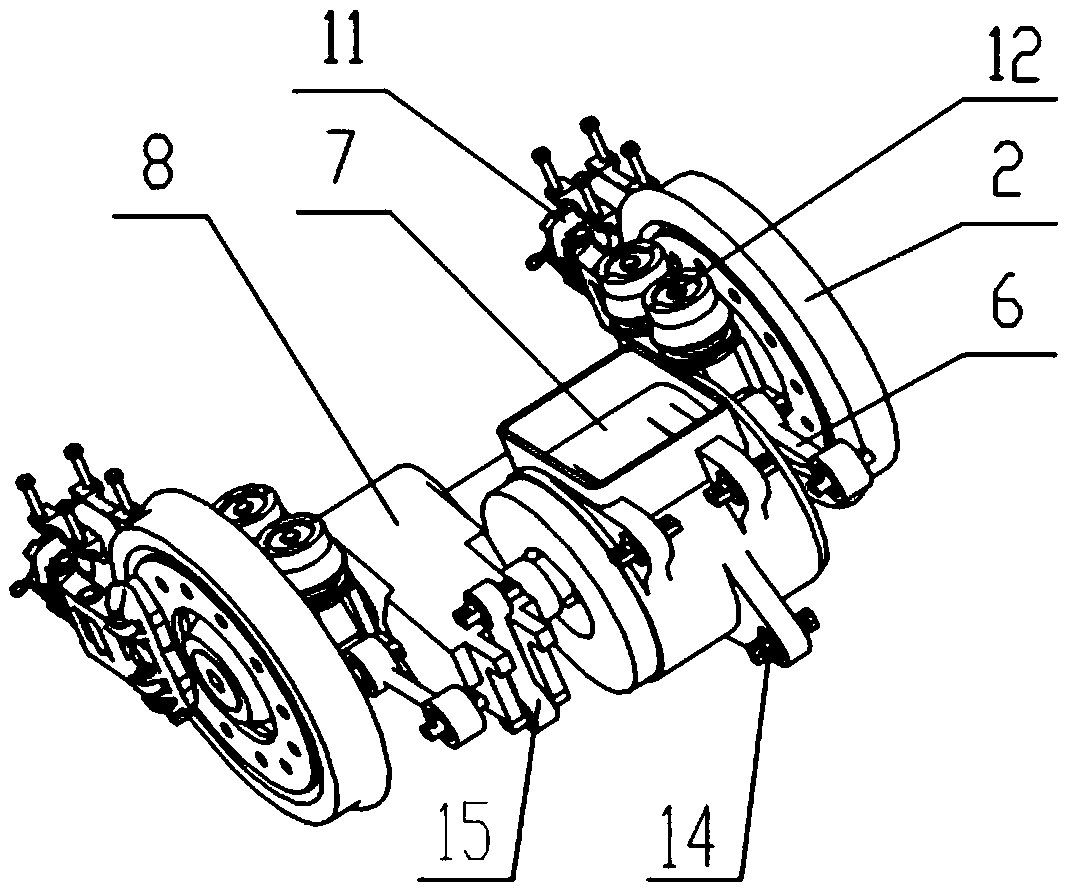

[0027] refer to figure 1 , figure 2 , the frame 1 of the bogie of the present invention is located inside the wheel set 2, and the axle box composition 3 is also located inside the wheel set 2. The primary suspension is composed of two rubber conical springs 12, a primary vertical shock absorber 5, and the axle box composition 3 and the frame 1 are connected and positioned through an axle box tie rod 6, a traction motor 7 and a gearbox 8 are installed inside the frame 1, an air spring 9 is installed in the middle of the frame 1, and an anti-snake shock absorber 10 is installed outside the middle of the frame 1, The disc brake caliper 11 is mounted on the end of the frame 1 . The transverse dimension of the entire bogie is small, which can meet the passing requirements of a small limit, and its bearing capacity and suspension parameters can meet the operating requirements of high-speed EMUs.

[0028] The axle box composition 3 of the bogie of the present invention is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com