Radiated-cooled glass and preparation method thereof

A technology of radiation cooling and glass, which is applied in the direction of coating, etc., can solve the problem of less research on radiation cooling glass, and achieve the effects of good lighting, transparent appearance, and excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

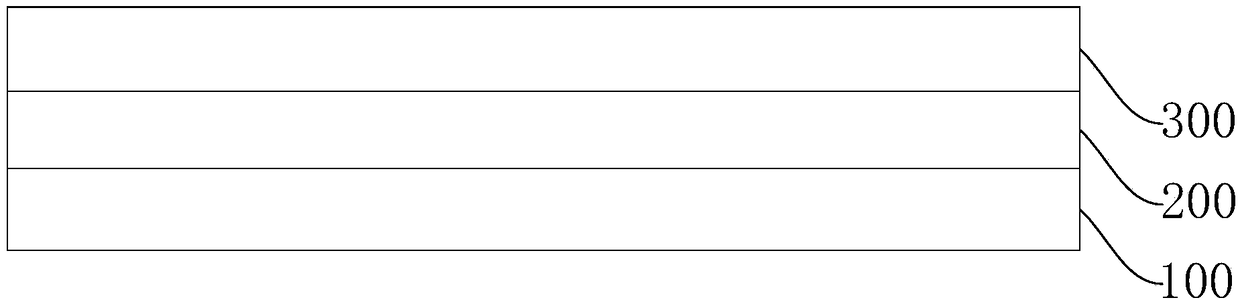

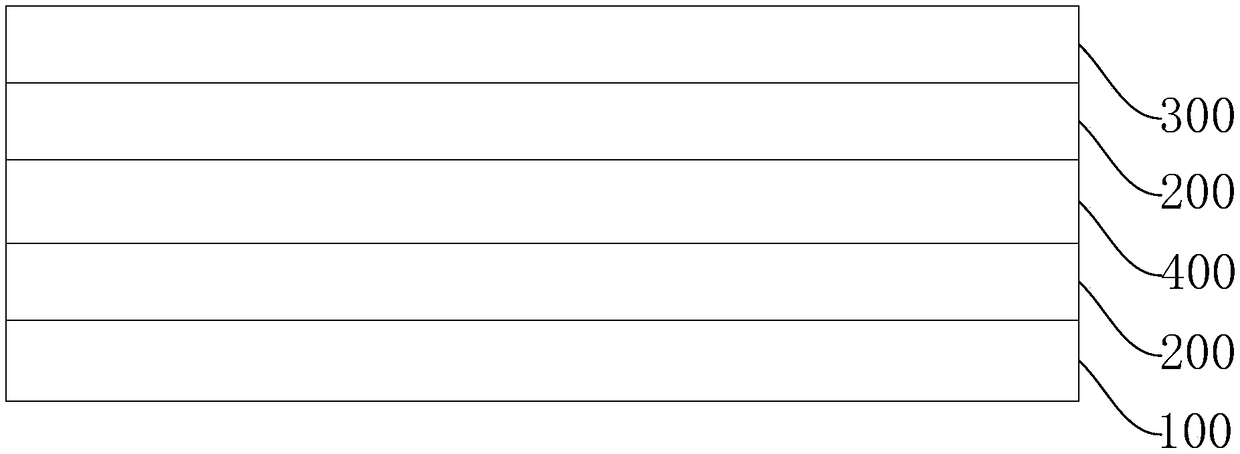

[0050] The present invention also provides a method for preparing radiation cooling glass, comprising the following steps:

[0051] S1, providing a glass substrate 100;

[0052] S2, depositing an oxide material on the glass substrate 100 to form at least one oxide layer 200, the oxide layer has a certain visible light transmittance and a high near-infrared reflectance;

[0053] S3, a resin material is provided on the outermost oxide layer 200, and cured to form the coating layer 300. The resin material includes a light-transmitting polymer material and inorganic particles dispersed in the polymer material, and the inorganic particles are 7-14 μm The band has a high emissivity.

[0054] In some embodiments, the inorganic particles of the coating layer 300 are selected from one or more of the following: SiO 2 , SiC, TiO 2 , CaCO 3 , BaSO 4 , the particle size of the inorganic particles is 4-20 μm.

[0055] In some embodiments, the above-mentioned light-transmitting polymer...

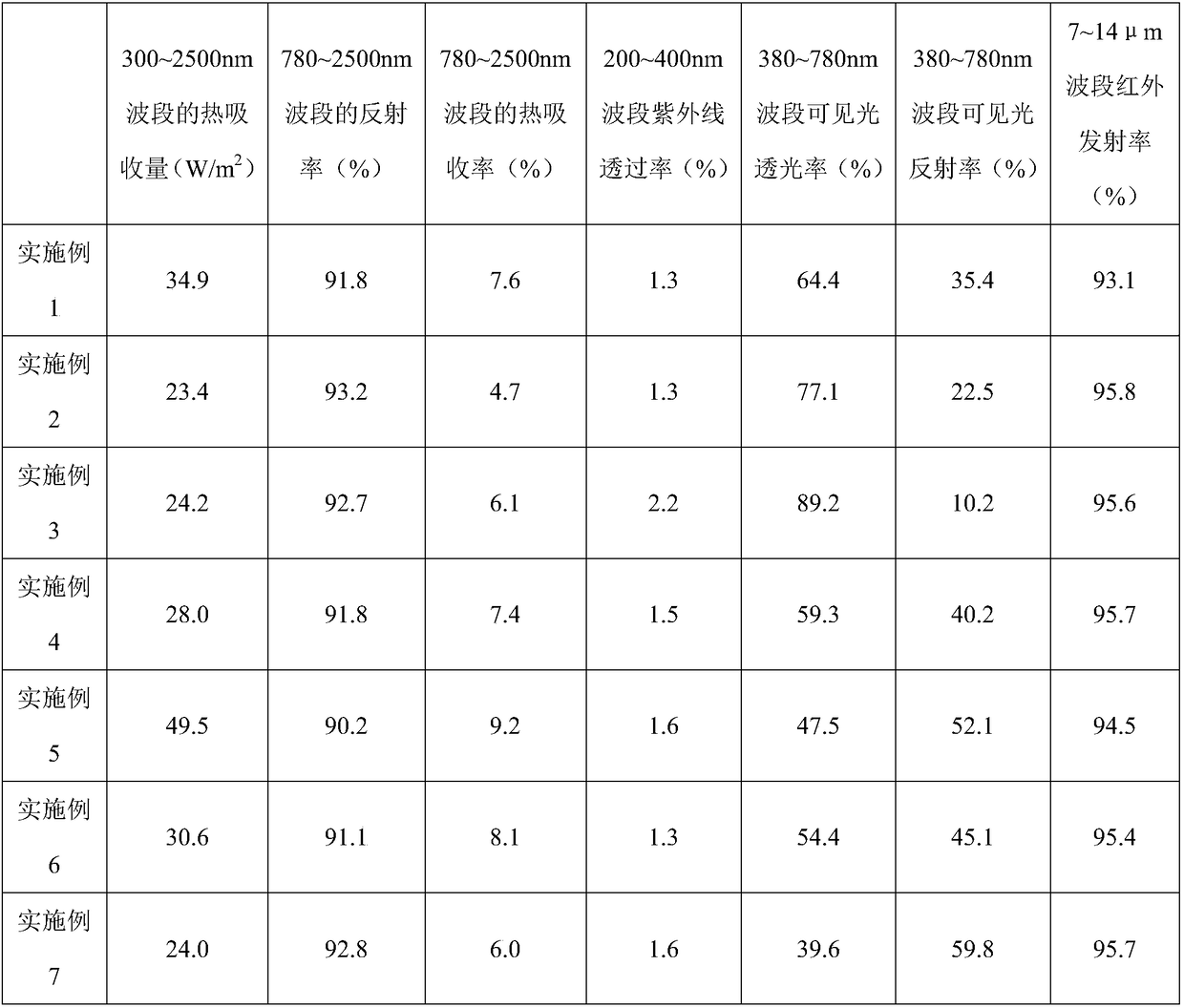

Embodiment 1

[0073] Radiatively cooled glass is prepared by:

[0074] Provide a thickness of 5mm inorganic transparent glass as the glass substrate 100;

[0075] Depositing Al on glass substrate 100 by offline vacuum sputtering 2 o 3 , to obtain an oxide layer 200 with a thickness of 50 nm;

[0076] Will include 97.5 parts by mass of polymethyl methacrylate, 2 parts by mass of SiO 2 A resin mixture of particles and 0.5 parts by mass of phenyl salicylate is coated on the oxide layer 200, and after curing, a coating layer 300 with a thickness of 10 μm is obtained, wherein SiO 2 The particle diameter of the particles was 4 μm.

Embodiment 2

[0078] Radiatively cooled glass is prepared by:

[0079] Provide a thickness of 5mm inorganic transparent glass as the glass substrate 100;

[0080] Deposition of TiO on glass substrate 100 by offline vacuum sputtering method 2 , to obtain an oxide layer 200 with a thickness of 50 nm;

[0081] Will comprise the polymethyl methacrylate of 94 mass parts, the TiO of 5.5 mass parts 2 The resin mixture of the particles and 0.5 parts by mass of phenyl salicylate was coated on the oxide layer 200 , and after curing, a coating layer 300 with a thickness of 10 μm was obtained, wherein the particle size of the SiC particles was 8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com