Tetracarboxylic acid for non-iron finishing and preparation and application of tetracarboxylic acid

A tetravalent carboxylic acid and non-ironing finishing technology, which is applied in the fields of sulfide preparation, fiber treatment, textiles and papermaking, etc., to achieve the effect of improving the problem of strength decline, good wrinkle recovery performance, strength retention rate, and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

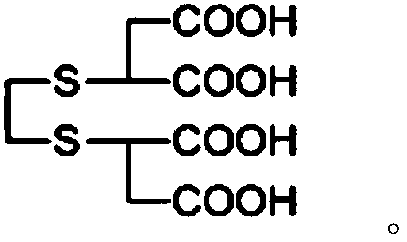

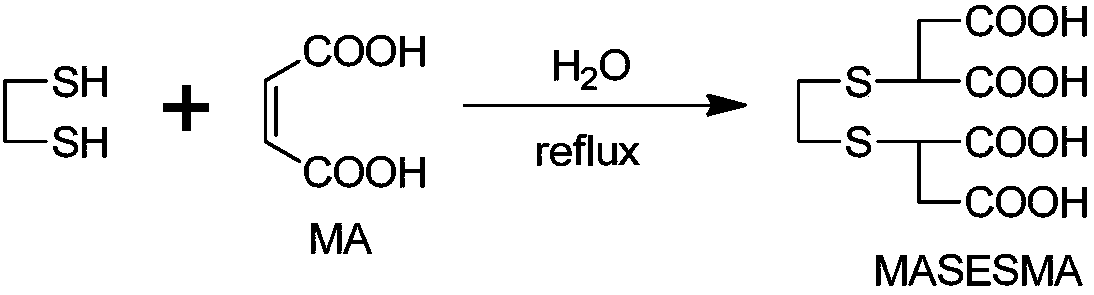

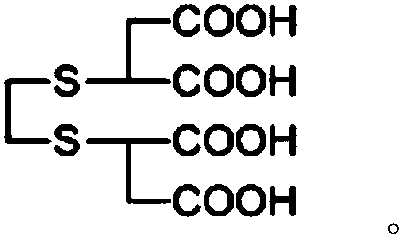

[0036] Get 22.5 grams of maleic acid (0.22mol) into a 250ml one-necked flask, add 100ml of water to dissolve. Then 8.4 ml of ethanedithiol (0.1 mol) and 1 ml of concentrated sulfuric acid were added to the solution. Then reflux for 12 hours. After the reaction was cooled, a precipitate was precipitated, and a white solid was obtained by suction filtration. After vacuum drying, 32.6 g of a dry solid was obtained, and the yield was 100% (calculated according to the amount of ethanedithiol).

Embodiment 2

[0038] Take 24.5 grams of maleic anhydride (0.25mol) and add it to a 250ml one-necked flask, and add 100ml of water to dissolve it. Then 8.4 ml of ethanedithiol (0.1 mol) and 1 ml of concentrated sulfuric acid were added to the solution. Then reflux for 6 hours. After the reaction was cooled, a precipitate was precipitated, and a white solid was obtained by suction filtration. After vacuum drying, 32.6 g of a dry solid was obtained, and the yield was 100% (calculated according to the amount of ethanedithiol).

Embodiment 3

[0040] A finishing solution with a mass concentration of tetravalent carboxylic acid of 60g / L and sodium hypophosphite of 80g / L. Cotton fabrics were dipped twice and rolled twice, and dried at 80°C for 3 minutes. Bake at 160°C for 180s. After one wash with water, the wrinkle recovery angle WRA=223°, the tear strength retention rate TSR=63.1%, and the whiteness WI=114.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com