Process for improving hygroscopicity of polyester fibers

A polyester fiber and hygroscopic technology, which is applied in the technical field of improving the hygroscopicity of polyester fiber, can solve the problems of restricting the application of information functional materials, biomedical materials and filter materials, and achieves the improvement of hydrophilicity and hygroscopicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

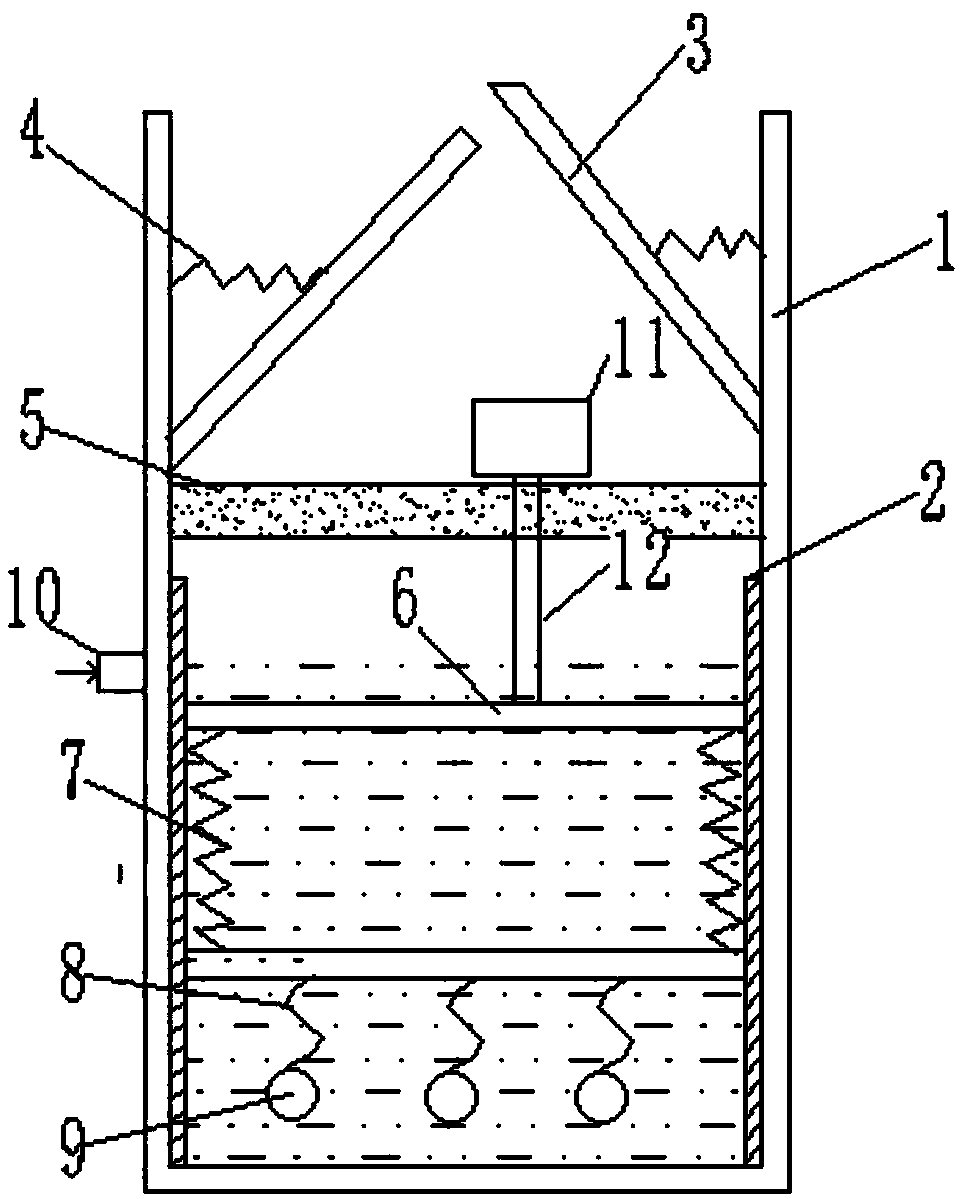

Image

Examples

Embodiment 1

[0035] A process for improving the hygroscopicity of polyester fibers, comprising:

[0036] 1) Preparation of liquid medium

[0037] Take 100 parts by weight of micro-electrolyzed water, 3 parts by weight of brown sugar, 1 part by weight of magnesium chloride, 1 part by weight of calcium chloride, 2 parts by weight of all-purpose flour, 1 part by weight of potassium phosphate and 1 part by weight of zinc sulfate, mix them under a pressure of 0.05MPa, Sterilize at a temperature of 80°C for 15 minutes to obtain a culture medium;

[0038] Add rice vinegar to the culture medium, adjust the pH of the mixture to a slightly acidic environment of 5.6-6.5, and obtain an acidic culture medium; let stand for 24 hours;

[0039] Add the pre-cultivated Myrocaria dewwet seed solution to the acidic culture medium, wherein the amount of the Myrocaria dewwet seed solution is 5% of the volume of the acidic culture medium, and leave it for 48 hours to obtain a liquid culture medium ;

[0040] ...

Embodiment 2

[0046] A process for improving the hygroscopicity of polyester fibers, comprising:

[0047] 1) Preparation of liquid medium

[0048] Take 100 parts by weight of micro-electrolyzed water, 3 parts by weight of brown sugar, 1 part by weight of magnesium chloride, 1 part by weight of calcium chloride, 2 parts by weight of all-purpose flour, 1 part by weight of potassium phosphate and 1 part by weight of zinc sulfate, mix them under a pressure of 0.05MPa, Sterilize at a temperature of 80°C for 15 minutes to obtain a culture medium;

[0049] Add rice vinegar to the culture medium, adjust the pH of the mixture to a slightly acidic environment of 5.6-6.5, and obtain an acidic culture medium; let stand for 24 hours;

[0050] Add the pre-cultivated Myrocaria dewwet seed solution to the acidic culture medium, wherein the amount of the Myrocaria dewwet seed solution is 5% of the volume of the acidic culture medium, and leave it for 48 hours to obtain a liquid culture medium ;

[0051] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com