Test method of double shield TBM tunneling tunnel surrounding rock rebound value

A test method and technology of rebound value, which are applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of limited observation range, error in observation results, interference of tunnel driving operations, etc., to achieve convenient measurement, intuitive measurement results, and accurate measurement. Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

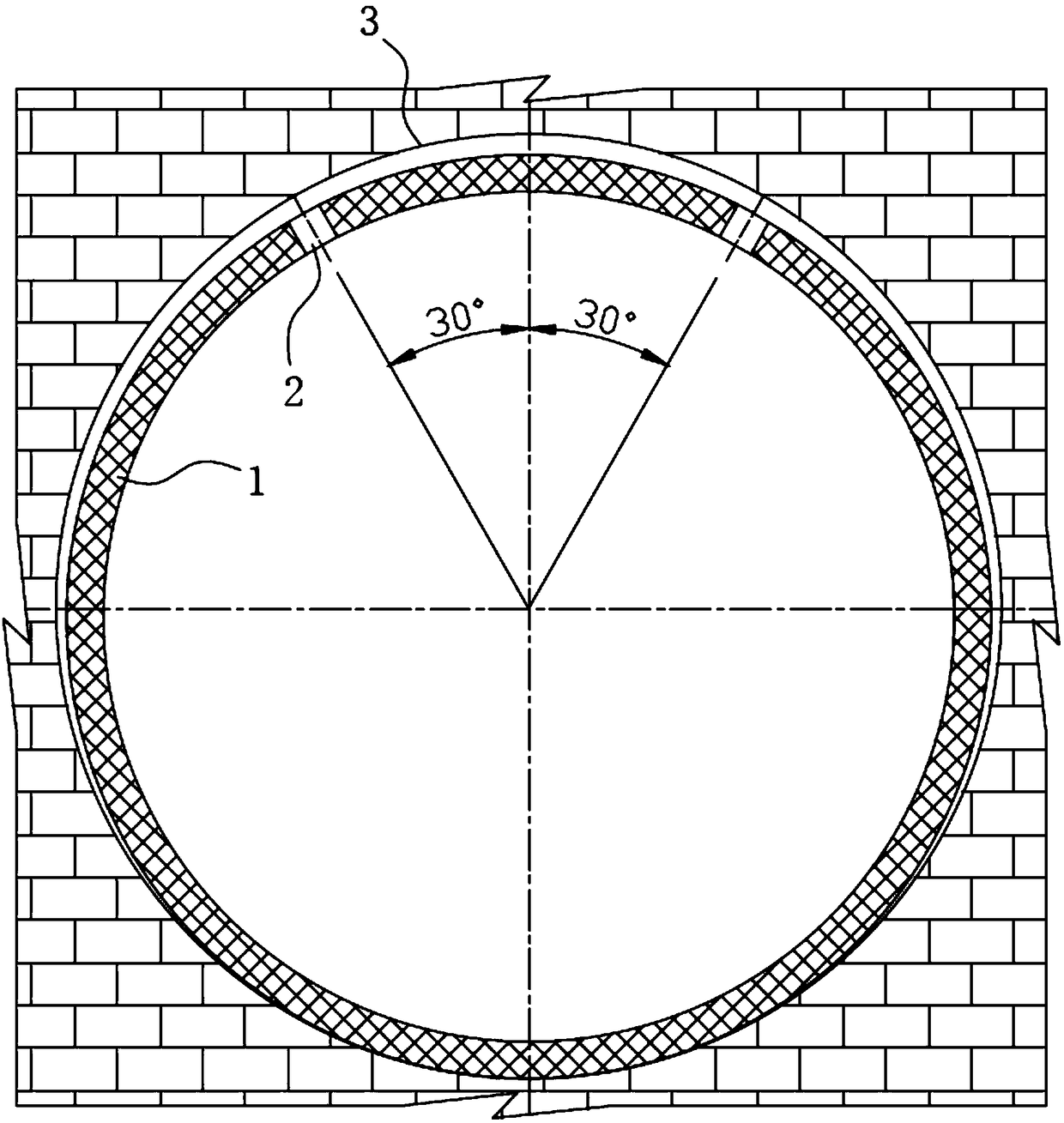

[0030] Such as figure 1 and figure 2 Shown in, the double-shield TBM excavation tunnel surrounding rock rebound value test method of the present invention, in the double-shield TBM excavation process, described surrounding rock rebound value test method comprises the following steps:

[0031] Step A, remove the tail shield after the corresponding segment 1 is installed;

[0032] Step B, filling the gap between the segment 1 and the rock wall 3 through the backfill hole 2 reserved on the segment 1;

[0033] Between the above steps A and B, the following steps C and D are also included:

[0034] Step C, opening the corresponding backfill hole 2 on the segment 1, and cleaning the loose rock mass in the backfill hole 2;

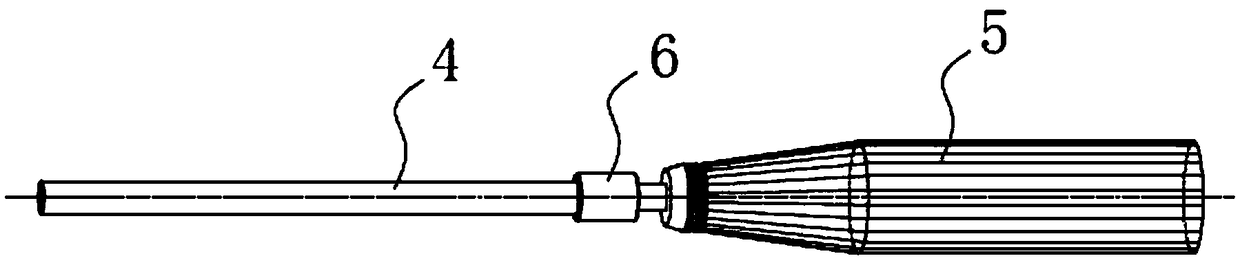

[0035] Step D, insert a rigid extension rod 4 into the backfill hole 2, and make one end of the extension rod 4 contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com