A wind wheel for motor heat dissipation and a fan including the wind wheel

A technology of motor heat dissipation and wind wheel, which is applied to machines/engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., which can solve problems such as inability to dissipate heat from the motor, reduced motor efficiency, and failure of electronic control, etc., to achieve a solution The effect of low motor efficiency, avoiding excessive temperature rise, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

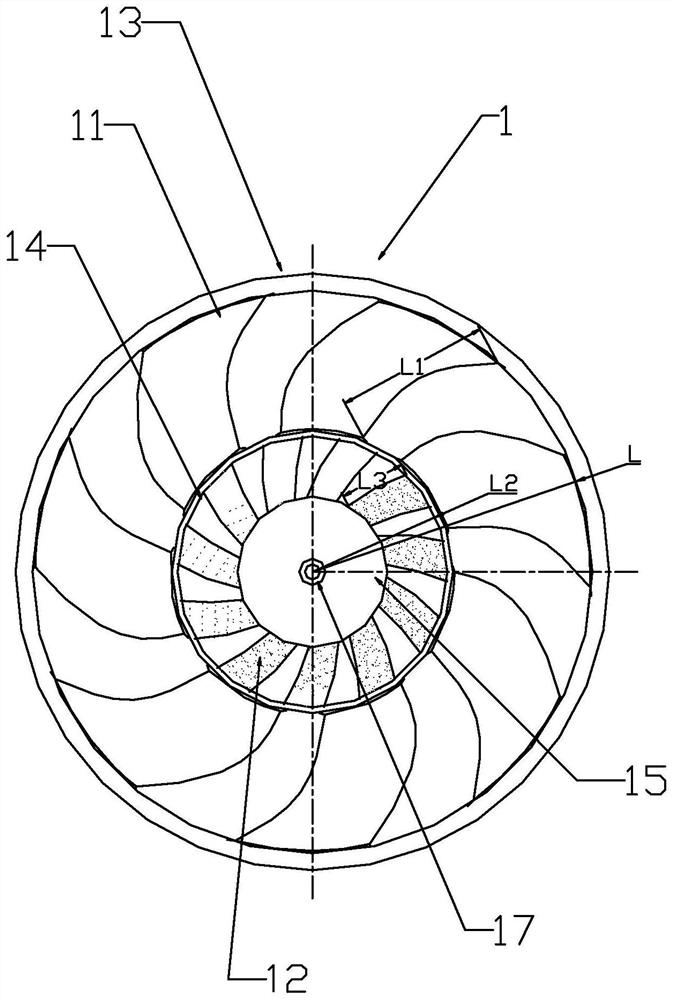

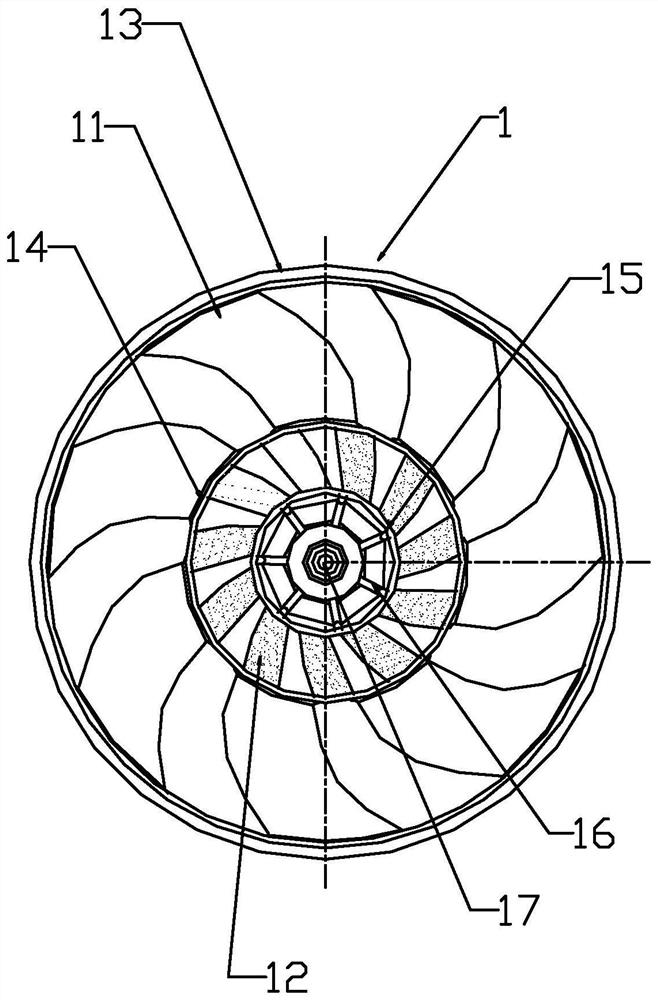

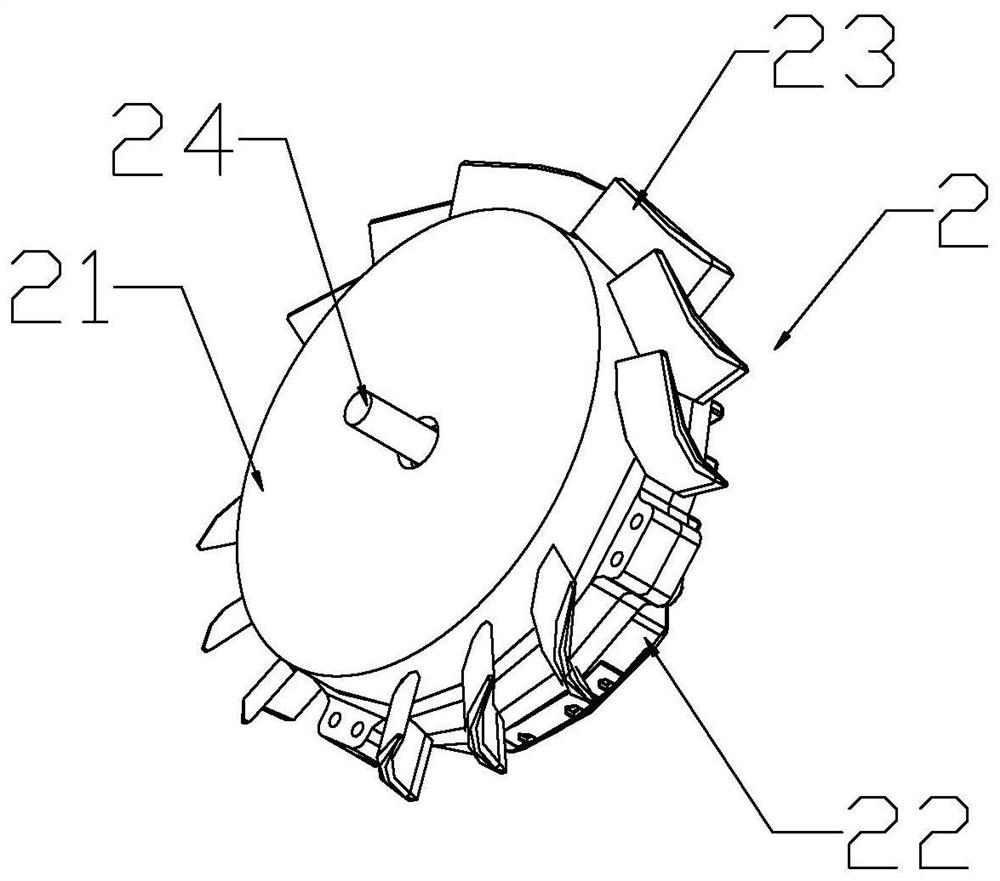

[0041] Such as figure 1 and 2 As shown, this embodiment discloses a wind wheel for motor heat dissipation, including a wind wheel hub 15, an inner wind guide ring 14, an outer wind guide ring 13, and a wind wheel hub 15 arranged on the inner wind guide ring 14 and the wind wheel hub 15. The inner blades 12 between them, the outer blades 11 arranged between the inner wind guide ring 14 and the outer wind guide ring 13, the inner blades 12 and the outer blades 11 are all based on the The central axis of the wind rotor hub 15 is the center of rotation, and the bending directions of the inner blades 12 and the outer blades 11 are the same. The blade root of the inner blade 12 is connected to the outer wall of the wind rotor hub 15, the blade tip of the inner blade 12 is connected to the inner wall of the inner wind guide ring 14, and the blade root of the outer blade 11 is connected to the inner wind guide ring. The outer wall of the ring 14 is connected, and the tip of the oute...

Embodiment 2

[0051] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, the relationship between the radius L of the wind wheel 1, the length L1 of the outer blade 11, the radius L2 of the inner circle of the inner wind guiding ring 14, and the length L3 of the inner blade 12 is: 0.2 L≦L1≦0.4L, 0.2L2≦L3≦0.4L2. Such setting is to ensure a sufficient ventilation system of the wind rotor 1 and excessive heat dissipation channels will affect the air volume of the wind rotor 1 .

Embodiment 3

[0053] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, the number of the outer blades 11 and the inner blades 12 are not in multiples, otherwise the fundamental and harmonic noise generated by the rotation of the outer blades 11 and the inner blades 12 will be superimposed, so that Wind wheel 1 produces abnormal noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com