Dual-purpose tank with phase change heat storage and temperature difference cold storage

A phase change heat storage and temperature difference technology, applied in the field of dual-purpose tanks, can solve problems such as low energy storage density, low system temperature, and complex system, and achieve the effects of saving operating costs, high energy storage density, and high operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

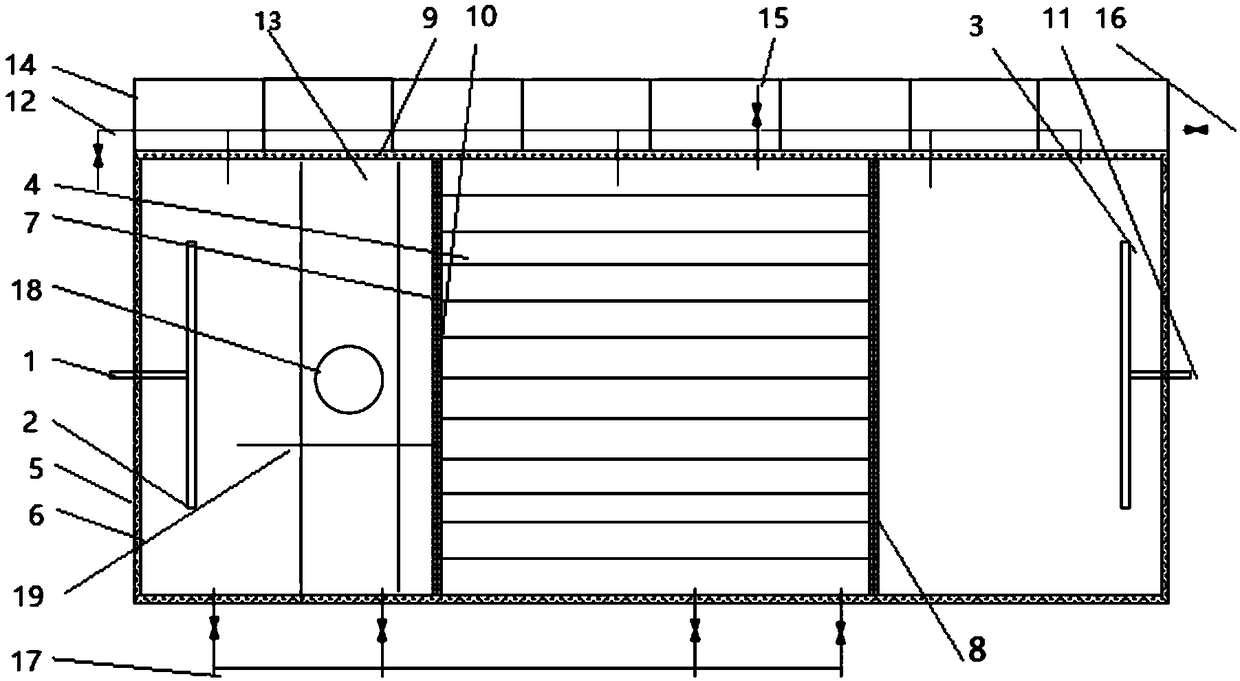

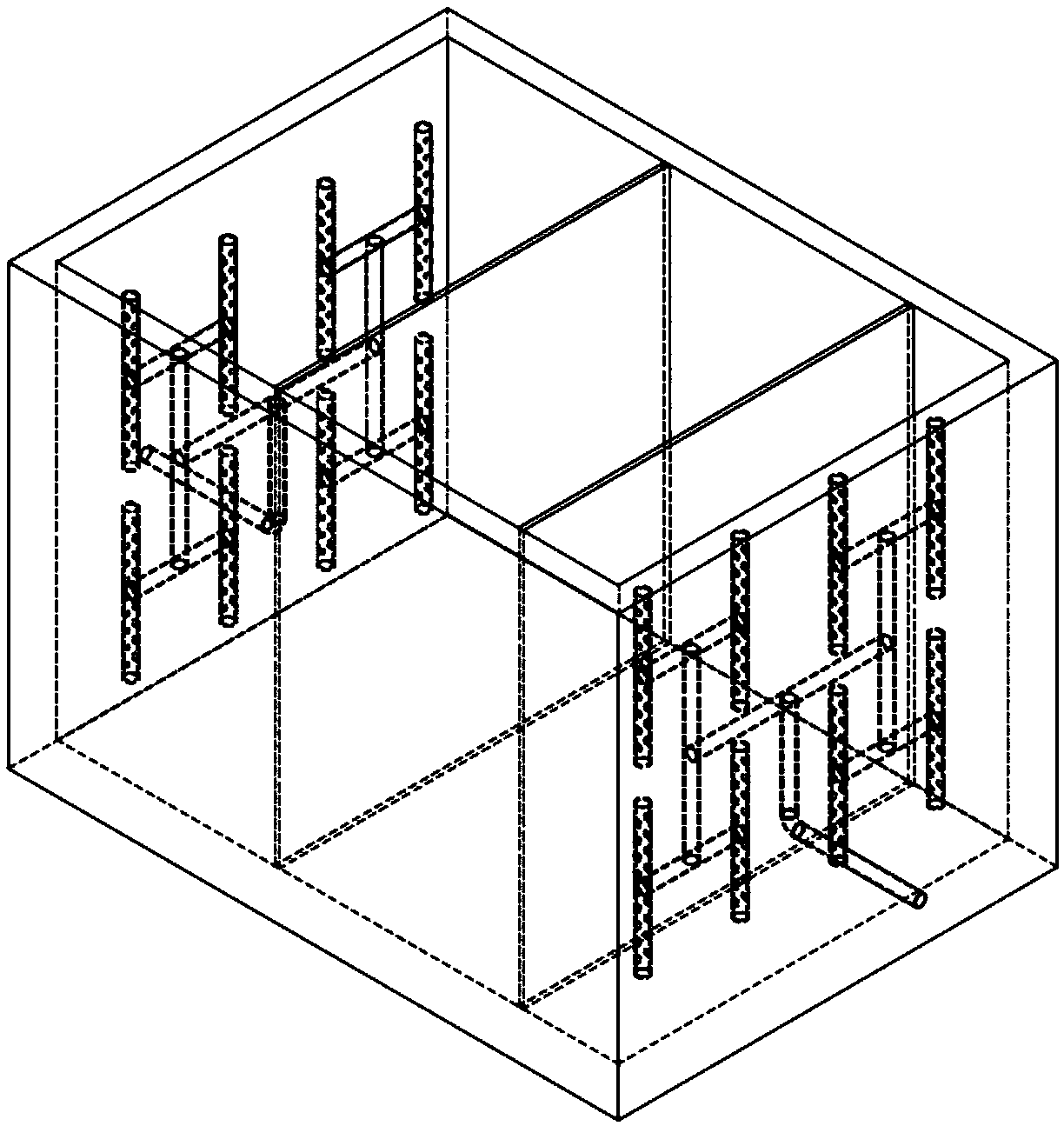

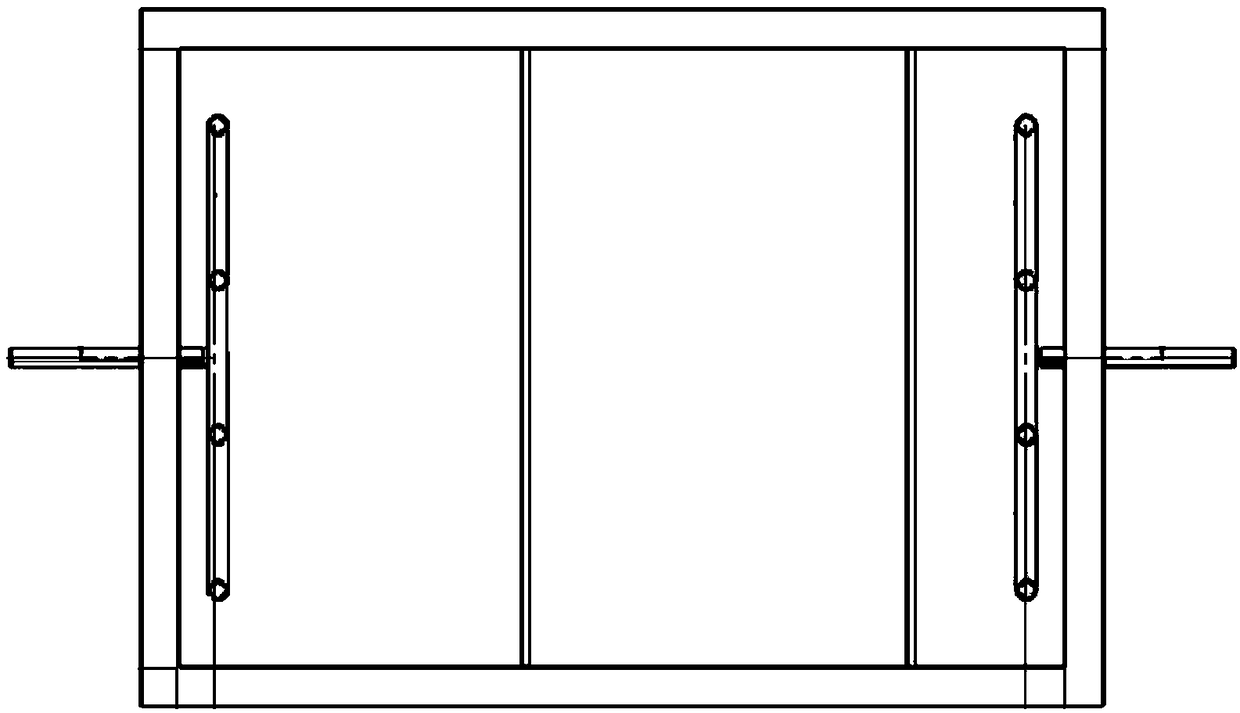

[0030] Such as Figure 1~4 As shown, a dual-purpose tank with phase change heat storage and temperature difference cold storage includes a closed tank body. In this embodiment, the tank body is a cuboid. The shell of the whole cuboid tank includes a steel inner wall 6 for maintaining the structure of the tank, and other materials can also be used to improve the service life and strength. The outer layer of the tank body is an insulation layer 5, which provides heat insulation for the tank body. The insulation layer 5 is attached to the steel inner wall 6, and the outer side of the insulation layer 5 is provided with a protective layer 9 for protecting the insulation material. The tank body is divided into three tank units, left, middle and right. The left and right tank units are respectively provided with an inlet and outlet, and the middle tank unit is provided with a phase change element 4 separated from the left and right tank units by a grid.

[0031] In this example, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com