Vertical detonator separating and mould arranging device used for automatic assembling and production of electronic detonators

An automatic assembly and electronic detonator technology, which is applied in the direction of weapon accessories, fuzes, ammunition, etc., can solve the problems of labor and low efficiency, and achieve the effect of convenient docking, not easy to fall off, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

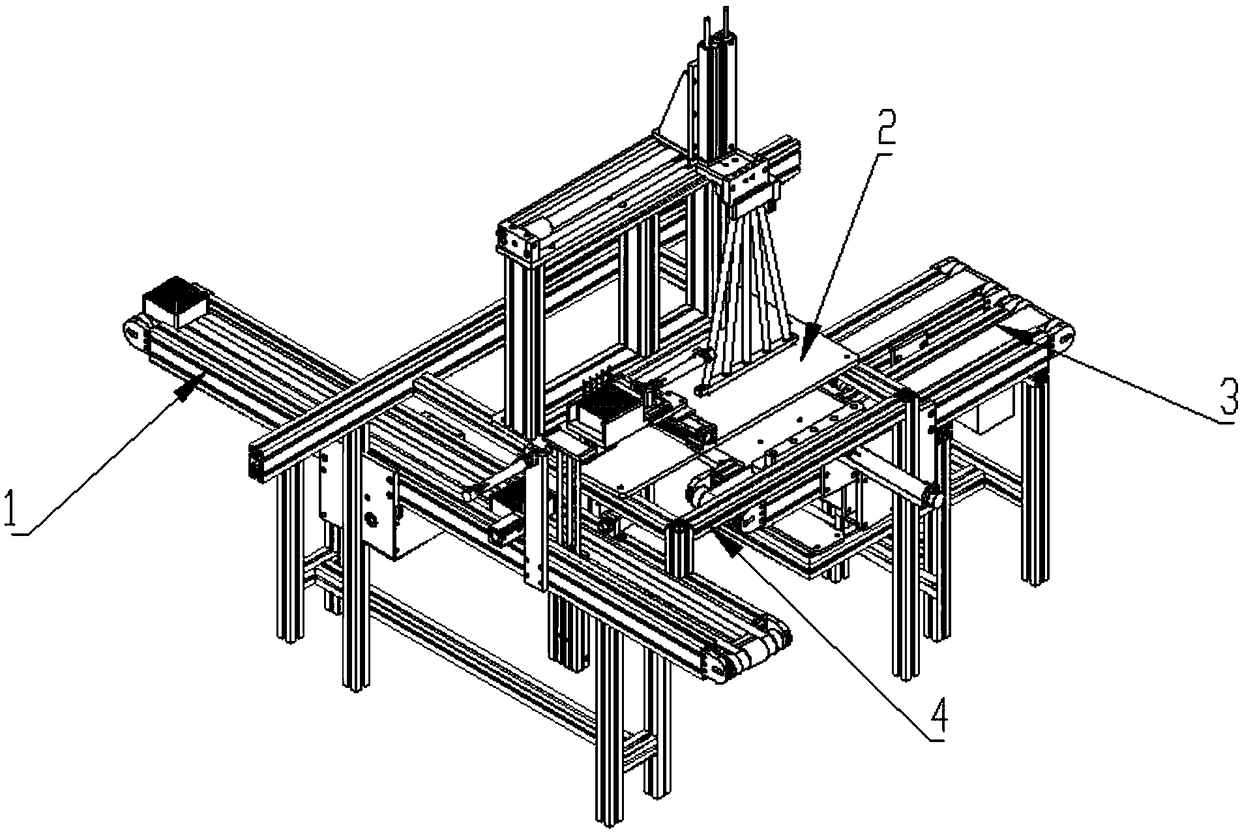

[0025] Embodiment 1, see Figure 1-Figure 9 , a vertical branching mold ejection device for the automatic assembly and production of electronic detonators, including a shell logistics line body assembly 1, a powder material handling assembly 2, a five-shot return flow line body assembly 3, and a fixed support frame 4; wherein: The powder handling assembly 2 is fixed on the top of the fixed support frame 4, the bottom side of the powder handling assembly 2 is provided with the shell flow line assembly 1, and the other side of the bottom of the powder handling assembly 2 is provided with five return flow line assemblies 3.

Embodiment 2

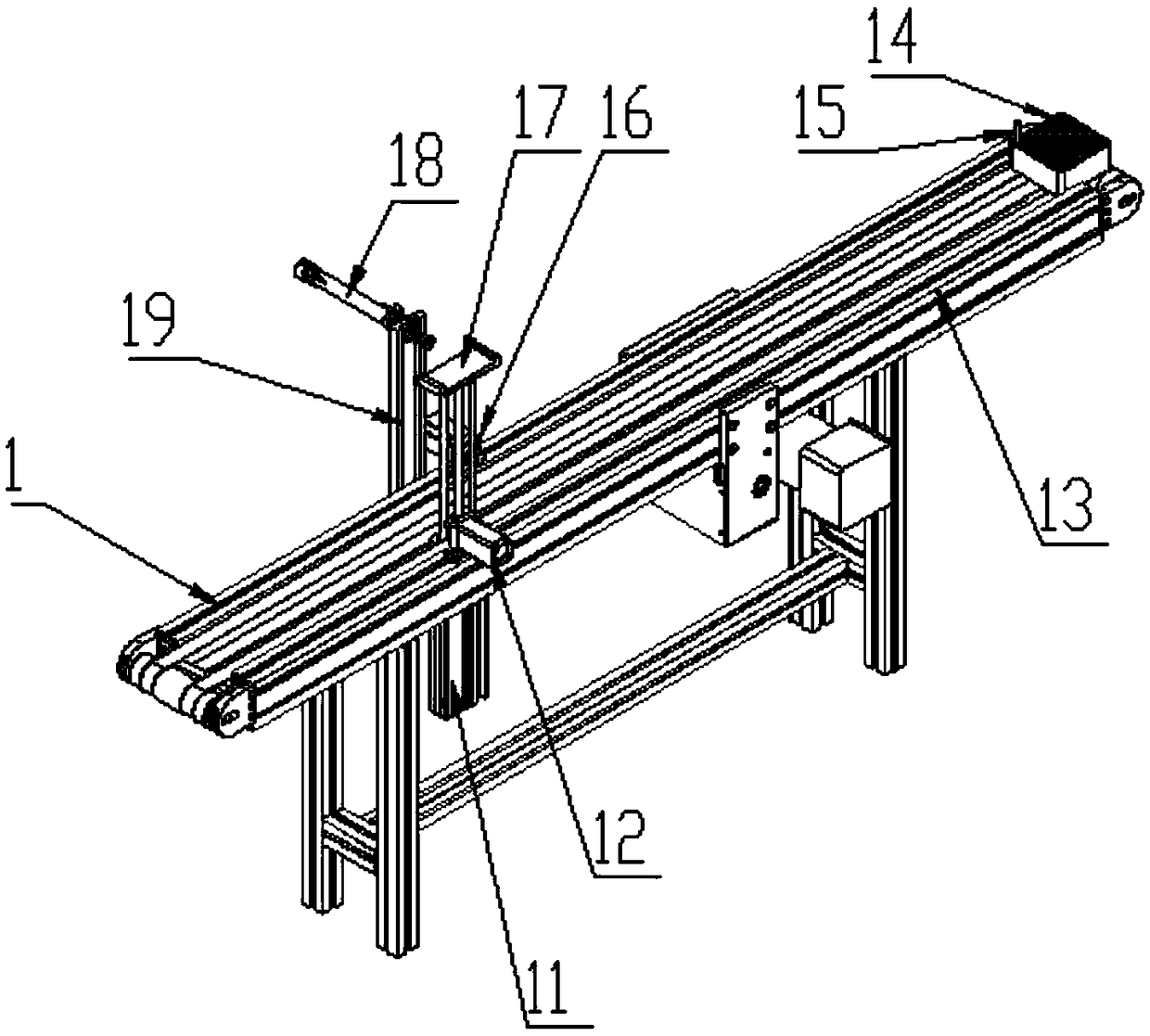

[0026] Example 2, see figure 2 , a vertical branching mold ejection device for the automatic assembly and production of electronic detonators, wherein: the shell logistics line body assembly 1 includes a collection and jacking cylinder 11, a first partition cylinder 12, a belt transmission mechanism 13, a collection box 14, Housing 15, second partition cylinder 16, collection box top plate 17, push cylinder 18, support plate 19, collection box 14 is placed in belt transmission mechanism 13, housing 15 is placed in collection box 14, belt transmission mechanism 13 side It is fixedly connected with the support plate 19, the top of the support plate 19 is fixedly provided with a push cylinder 18, and the middle part of the belt transmission mechanism 13 is fixedly provided with a collection jacking cylinder 11, and the top of the collection jacking cylinder 11 is fixedly connected with the bottom of the collection box top plate 17, and the belt transmission mechanism 13 top side...

Embodiment 3

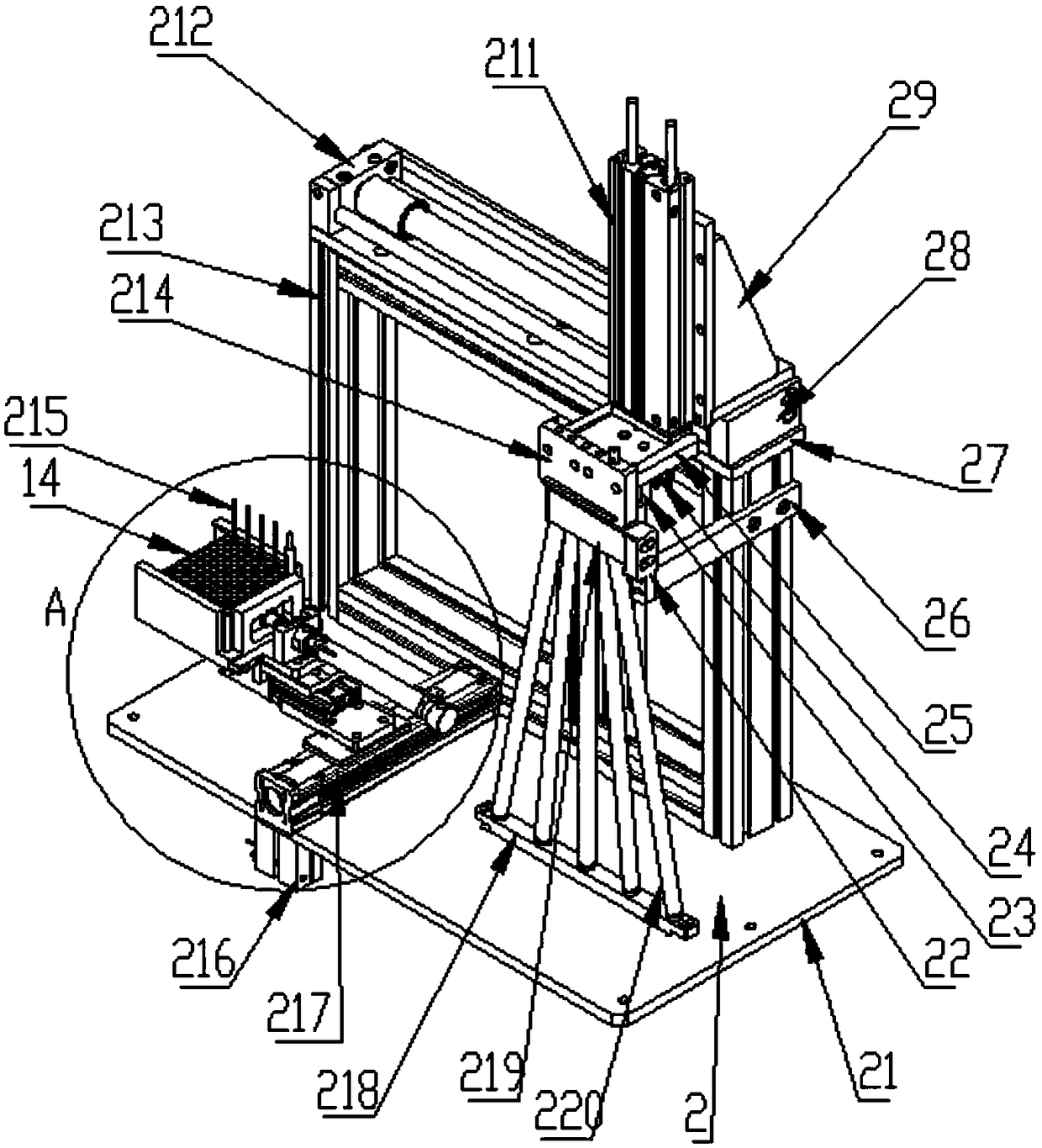

[0027] Example 3, see image 3 and Figure 4, a vertical branching mold ejection device for the automatic assembly and production of electronic detonators, wherein: the powder handling assembly 2 includes a support table 21, a first support frame 22, a shell support plate 23, a clamping hole 23a, and a support plate cylinder 24 , Z-axis connecting plate 25, second support frame 26, carrying cylinder seat 27, reinforcing plate fixing block 28, reinforcing plate 29, second carrying cylinder 211, first carrying cylinder 212, square support frame 213, material distribution plate 214, The first housing through hole 214a, the card slot 214b, the chrome-plated rod 215, the third carrying cylinder 216, the screw motor 217, the shell receiving plate 218, the second housing through hole 218a, the blanking plate 219, the air pipe 220, Collection box fixed plate 221, the first push plate 222, the second push cylinder seat 223, slide cylinder 224, slide cylinder seat 225, the second push ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap