Distance-adjustable laser level

A technology of laser marking instrument and spacing adjustment, applied in the field of laser marking instrument, can solve the problems of insufficiency, accidental drop of the instrument, bending of the shaft system, etc., and achieves the effect of simple structure and shortening of construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

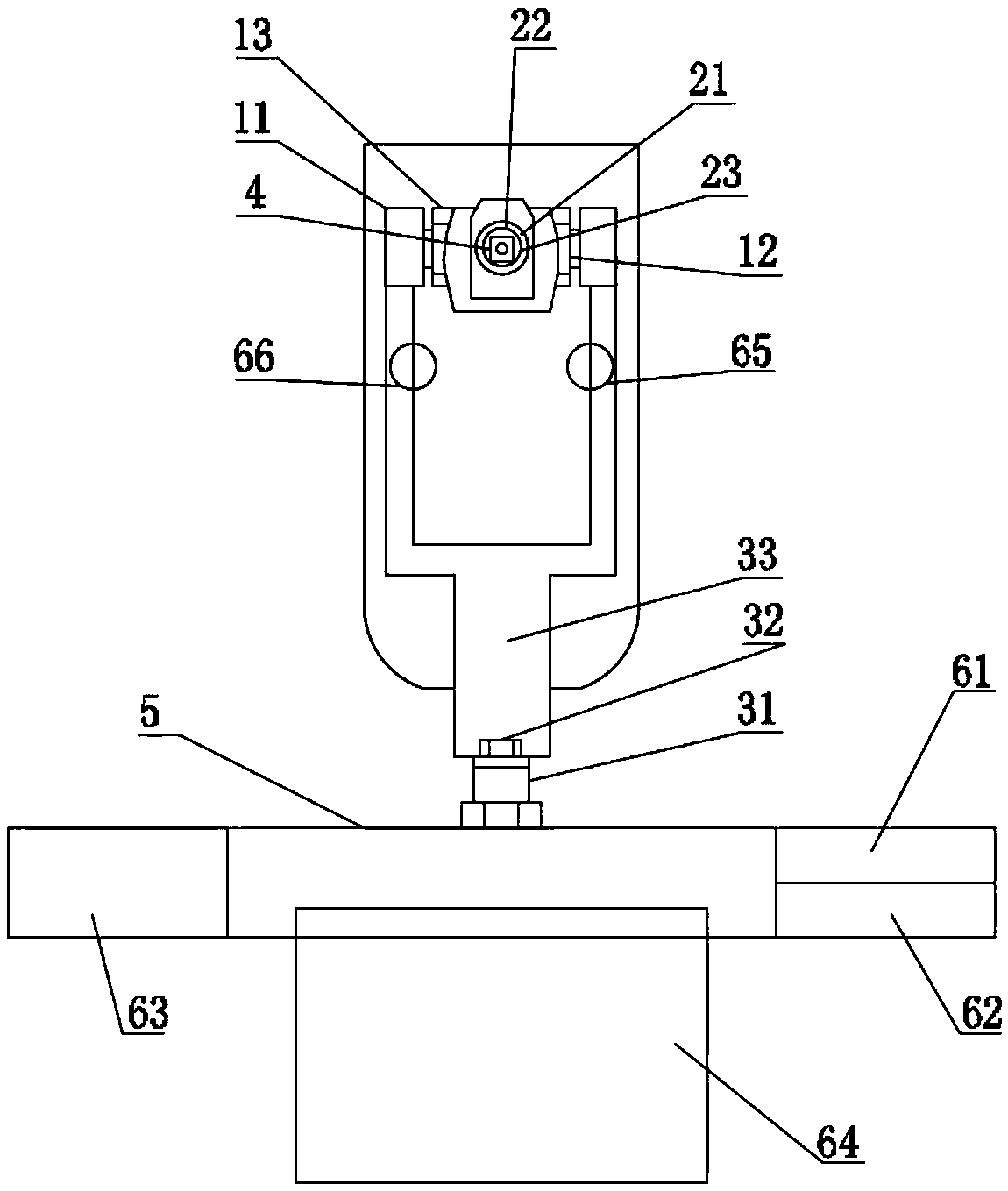

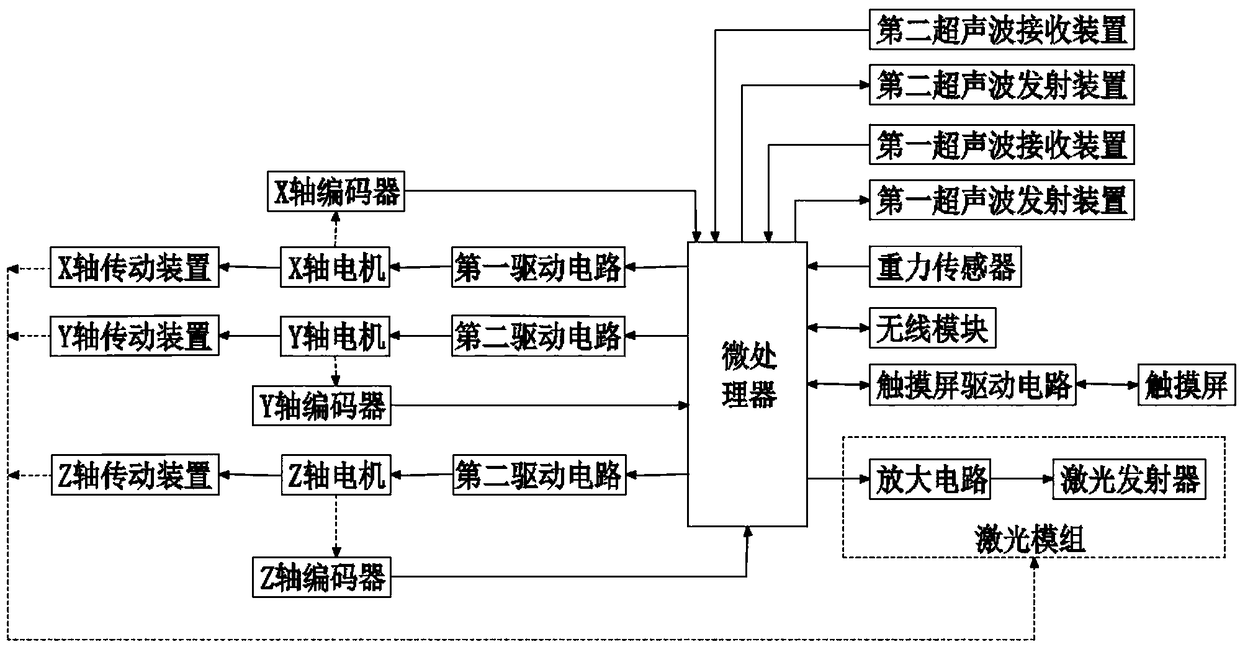

[0033] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a laser marking instrument with adjustable spacing includes a housing 5, a driving device, a control system and a power supply;

[0034] Described driving device comprises motor and transmission device, and motor comprises X-axis motor 11, Y-axis motor 21 and Z-axis motor 31, and transmission device comprises X-axis transmission device, Y-axis transmission device and Z-axis transmission device, in order to make transmission device more Simple, faster response, the transmission device adopts the turret, wherein the X-axis transmission device adopts the X-axis turret 13, the Y-axis transmission device adopts the Y-axis turret 23, the Z-axis transmission device adopts the Z-axis turret 33, and the Z-axis motor One end of 31 is connected to the Z-axis turret 33, and the other end is arranged on the housing 5. The Z-axis motor is used to drive the Z-axis turret 33 to rotate around the Z-axis. One end of the X...

Embodiment 2

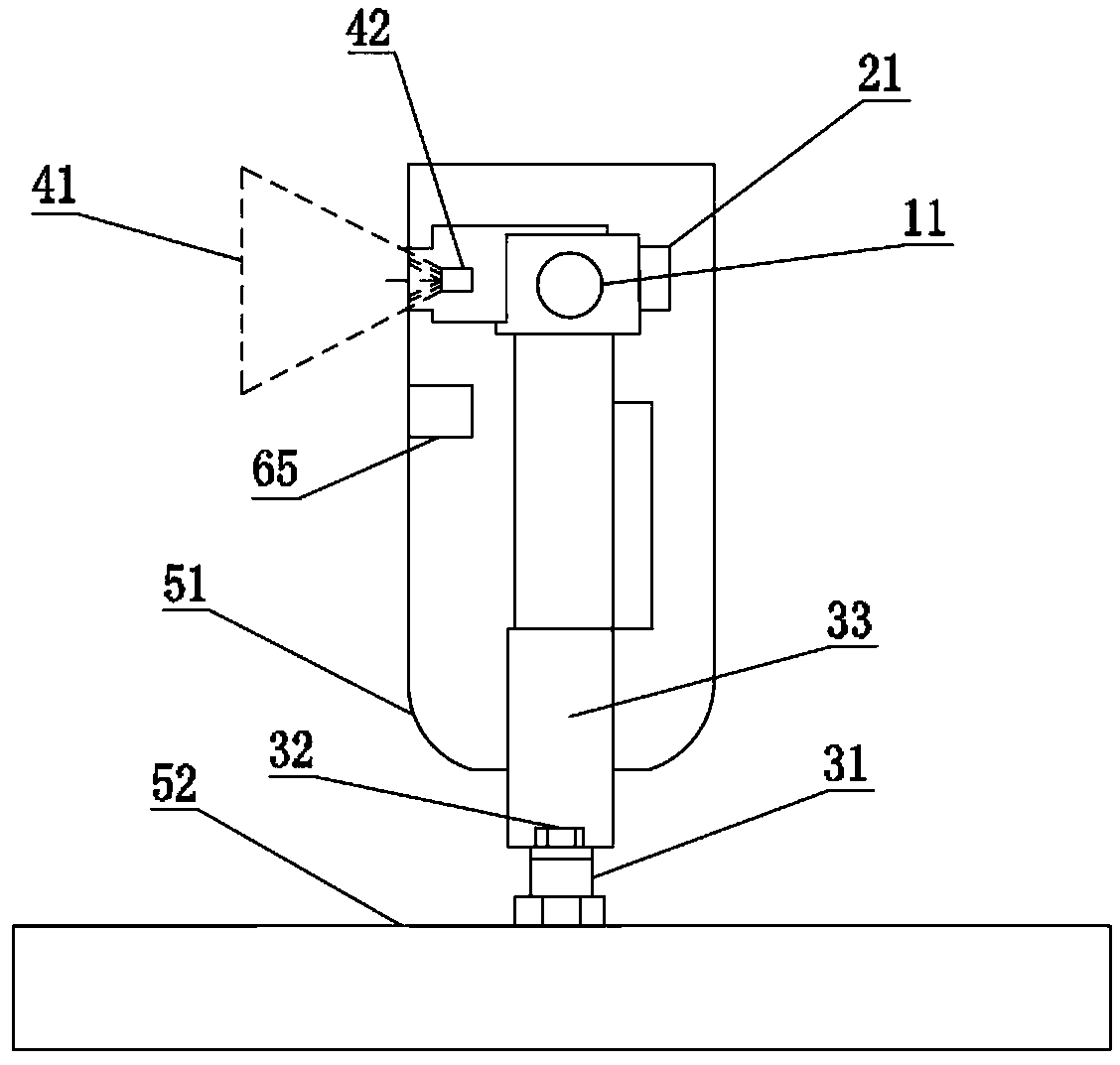

[0046] Such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a laser marking instrument with adjustable spacing includes a housing 5, a driving device, a control system and a power supply;

[0047] Described driving device comprises motor and transmission device, and motor comprises X-axis motor 11, Y-axis motor 21 and Z-axis motor 31, and transmission device comprises X-axis transmission device, Y-axis transmission device and Z-axis transmission device, in order to make transmission device more Simple, faster response, the transmission device adopts the turret, wherein the X-axis transmission device adopts the X-axis turret 13, the Y-axis transmission device adopts the Y-axis turret 23, the Z-axis transmission device adopts the Z-axis turret 33, and the Z-axis motor One end of 31 is connected to the Z-axis turret 33, and the other end is arranged on the housing 5. The Z-axis motor is used to drive the Z-axis turret 33 to rotate around the Z-axis. One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com