Multi-sensor arrangement device for temperature and humidity detection and calibration of constant-temperature and constant-humidity box

A constant temperature and humidity chamber, temperature sensor technology, applied in the direction of instruments, etc., can solve the problems of high labor intensity, low efficiency and affecting the accuracy of test results for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

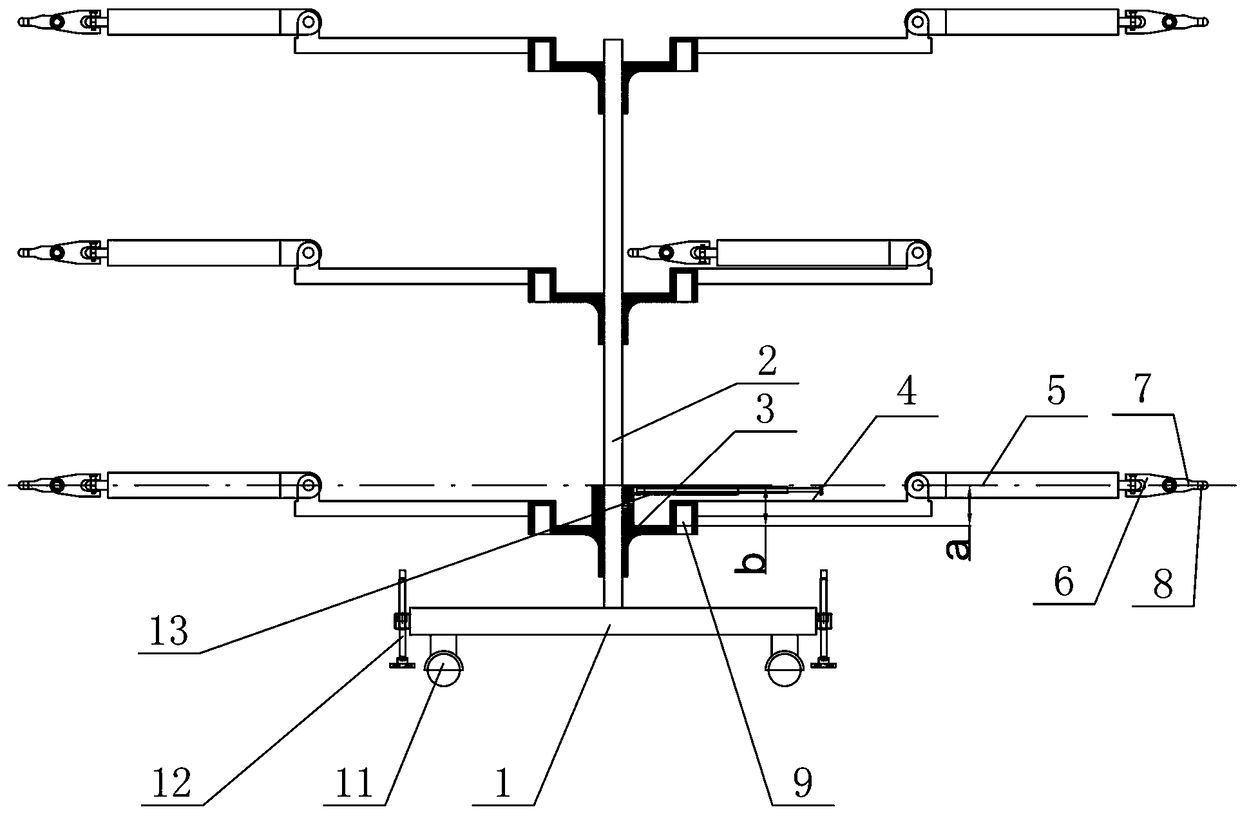

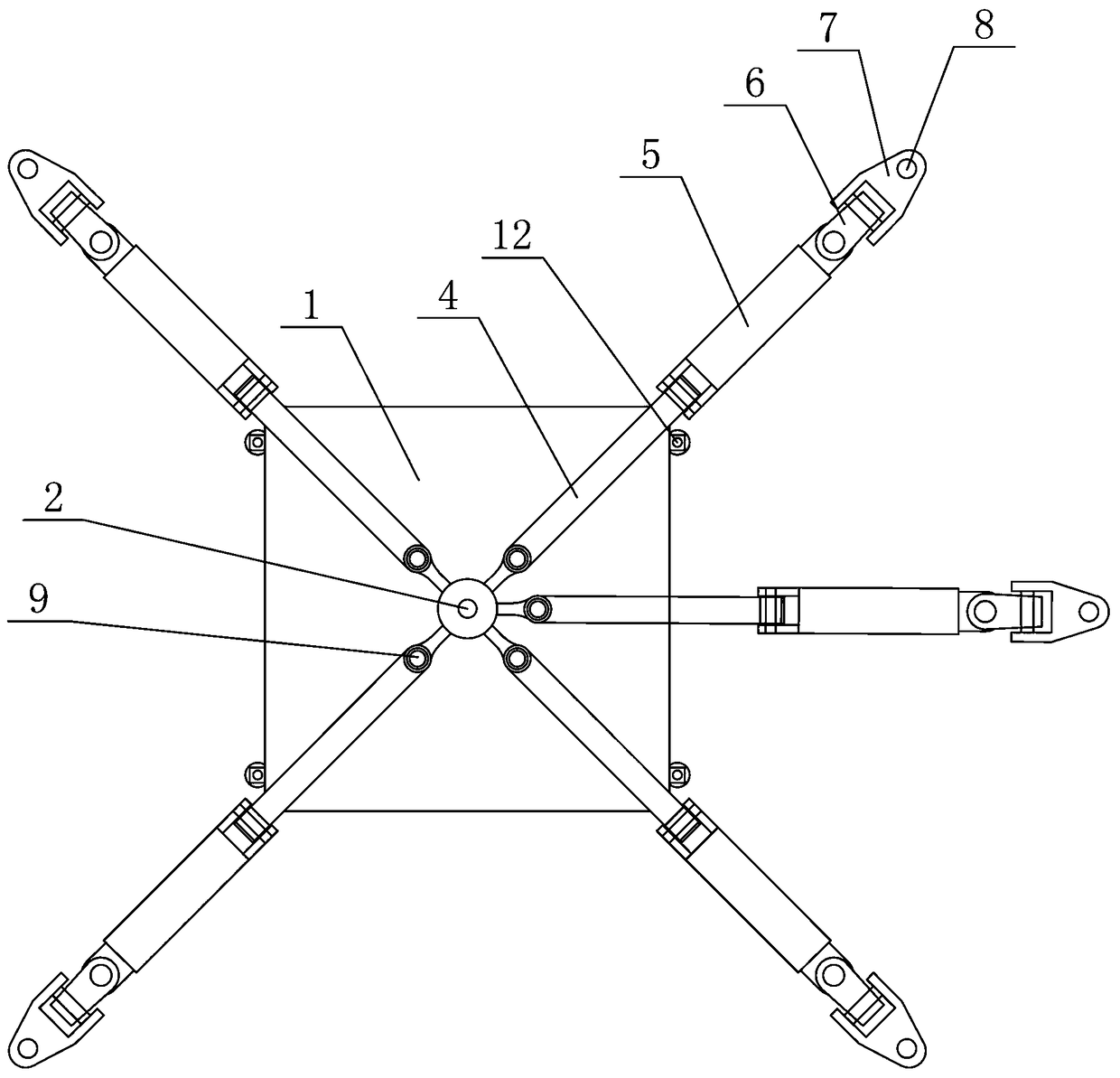

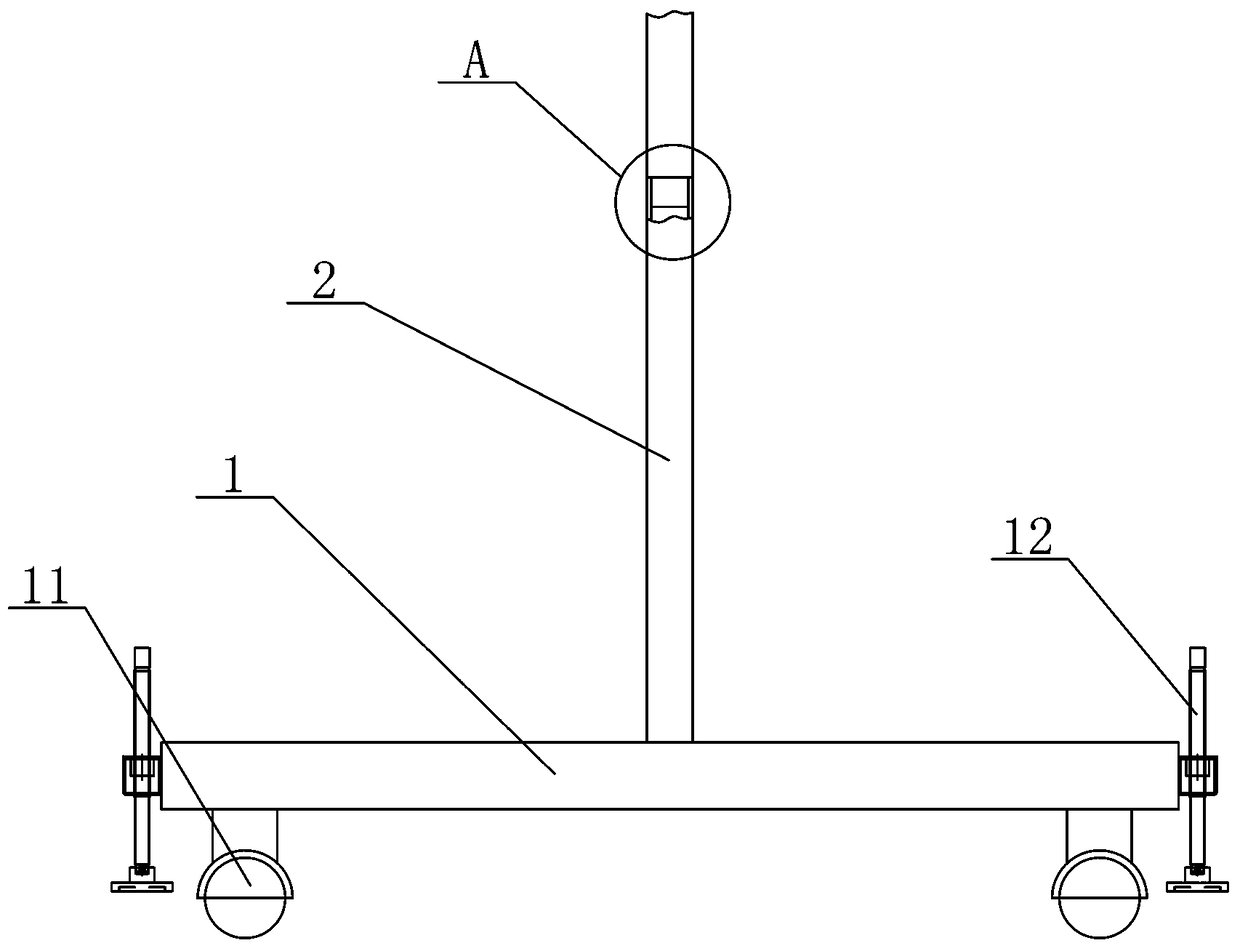

[0064] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a multi-sensor arrangement device for temperature and humidity detection and calibration of a constant temperature and humidity chamber, including a base 1, a column 2, a support base 3, a cantilever 4, an extension arm 5 and a sensor bracket 7, the lower end of the base 1 is provided with ten thousand To the roller 11, the base 1 is provided with a support rod 12, and the support rod 12 is provided with a scale line along its height direction. The base 1 is provided with a column 2, and the column 2 is formed by sequentially connecting a plurality of short tubes 21. The lower ends of the short tubes 21 are provided with external threads, and the upper ends of the short tubes 21 are provided with connecting internal threads. On the outer wall of the short tube 21, a height scale line is arranged along its height direction. The ...

Embodiment 2

[0093] Such as Figure 12 Shown, repeat embodiment one, have following difference: as Figure 12 As shown, A, B, C, D, E, F, G, H, I, J, K, L, M, N, O are temperature sensor detection points, A, B, C, D are humidity sensor detection points , the present embodiment is to carry out calibration detection for the constant temperature and humidity box with an internal volume greater than 2 cubic meters, and its detection points are designed as follows: the number of detection points is 15, and 15 temperature sensors and 4 humidity sensors are arranged at 15 detection points. The 15 detection points are divided into upper, middle and lower layers. The distance between the upper layer and the top surface of the constant temperature and humidity chamber = 1 / 10h~1 / 10h +5cm. The middle layer is located at the center of the height of the constant temperature and humidity chamber. The distance between the bottom surfaces of the constant temperature and humidity chamber = 1 / 10h~1 / 10h + 5c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com