A pulsed eddy current detection device and method based on frequency domain lift-off cross point

A pulsed eddy current and detection device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to eliminate the effect of lift-off, improve detection accuracy, and suppress the effect of lift-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

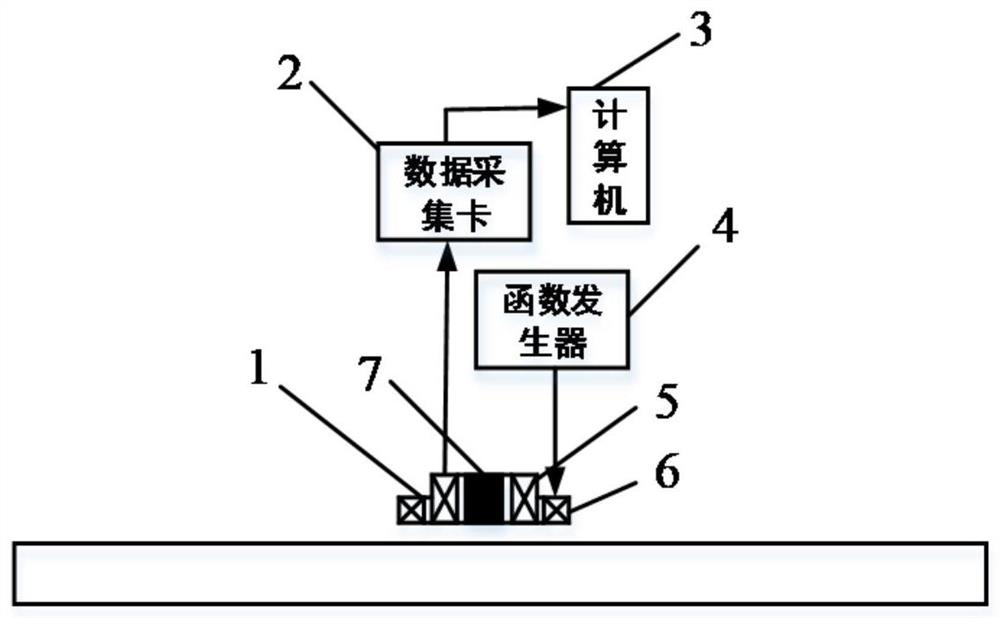

[0048] figure 1 It is a structural block diagram of a pulsed eddy current thickness measuring device according to an embodiment of the present invention.

[0049] The pulsed eddy current detection device includes: a probe 1, a data acquisition card 2, a computer 3 and a function generator 4; the output end 4 of the function generator is connected to the input end of the probe 1, and the output end of the probe 1 is connected to the computer 3 through the data acquisition card 2 connect.

[0050] The probe 1 is a coil probe with an iron core, comprising: a probe excitation coil 5, a probe detection coil 6 and an iron core 7; the iron core 7 is located at the center of the probe 1, and the probe excitation coil 5 and the probe are sequentially wound outside the iron core 7 The detection coil 6; the probe excitation coil 5 receives the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com