Variable frequency capacity increasing motor stator punching sheet, variable frequency capacity increasing motor stator and stator winding line inserting method

A technology for motor stator and stator punching, which is used in electric components, manufacturing motor generators, and the shape/style/structure of winding conductors, etc. problem, to achieve the effect of good ventilation, reduce the temperature rise of the motor, and improve the load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

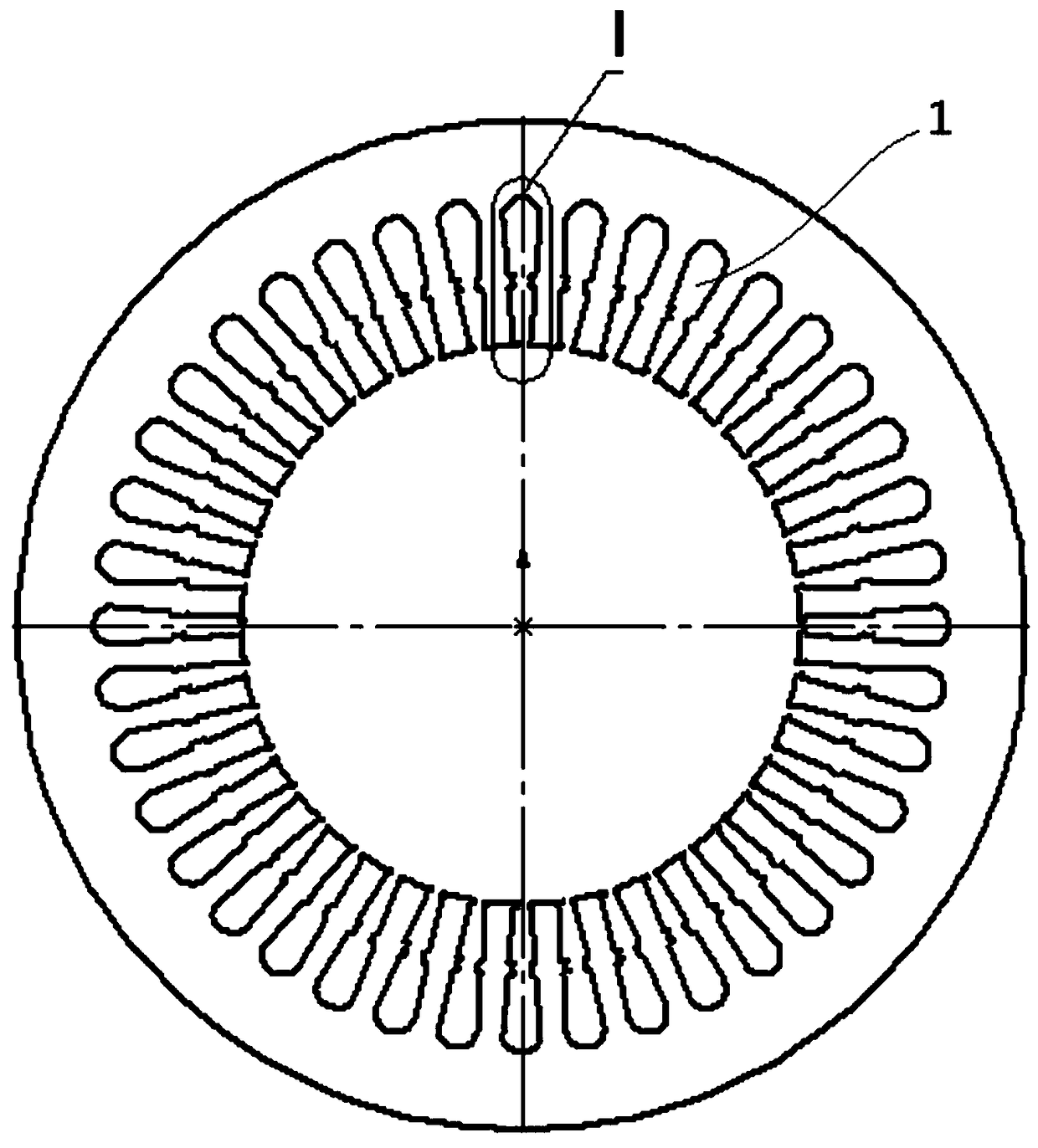

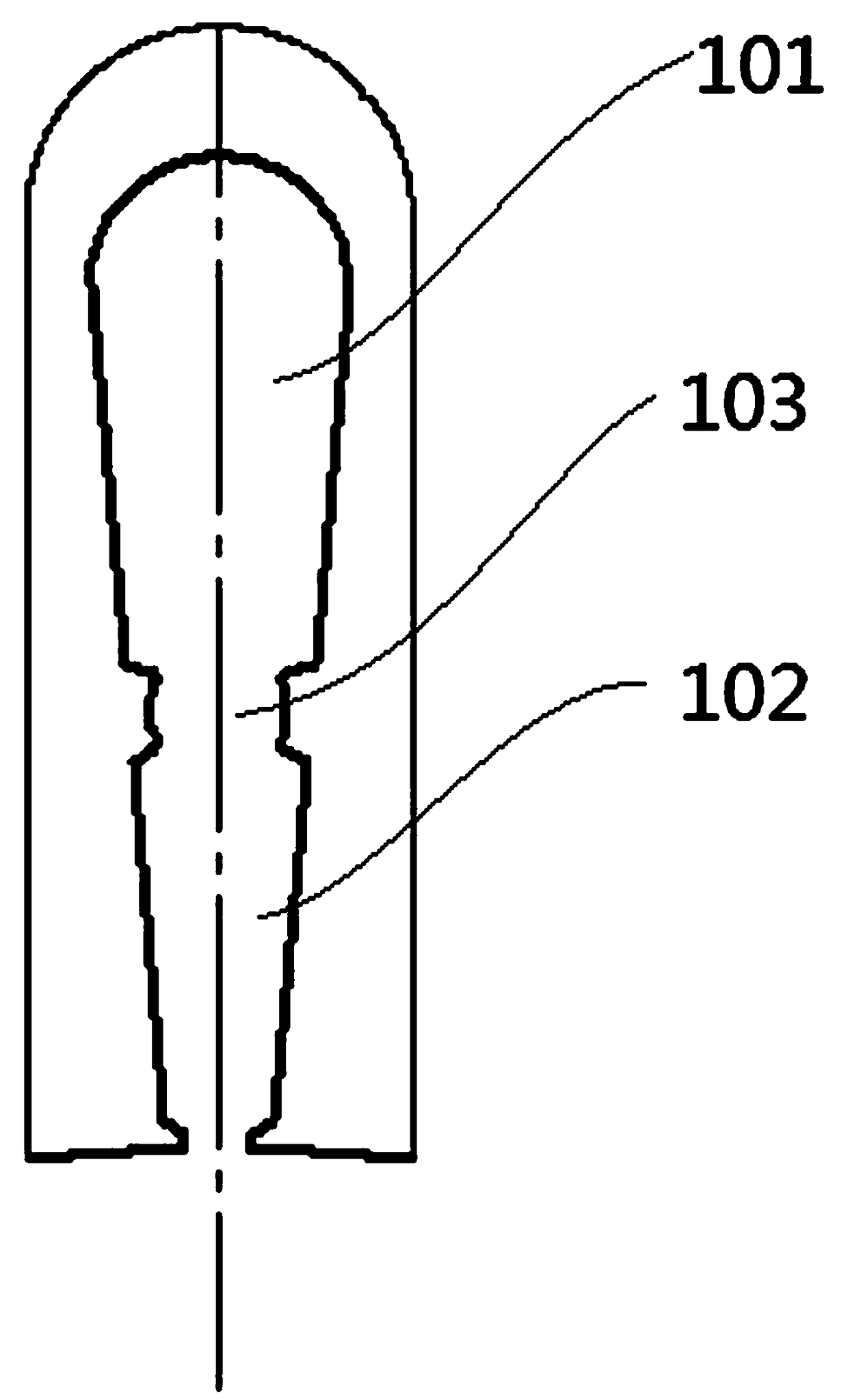

[0027] Such as Figure 1-2 As shown, a stator punching plate of a variable frequency and capacity increasing motor includes uniformly distributed stator slots 1, each stator slot 1 includes an inner slot 102 and an outer slot 101, and a vent 103 is passed between the inner slot 102 and the outer slot 101 connected.

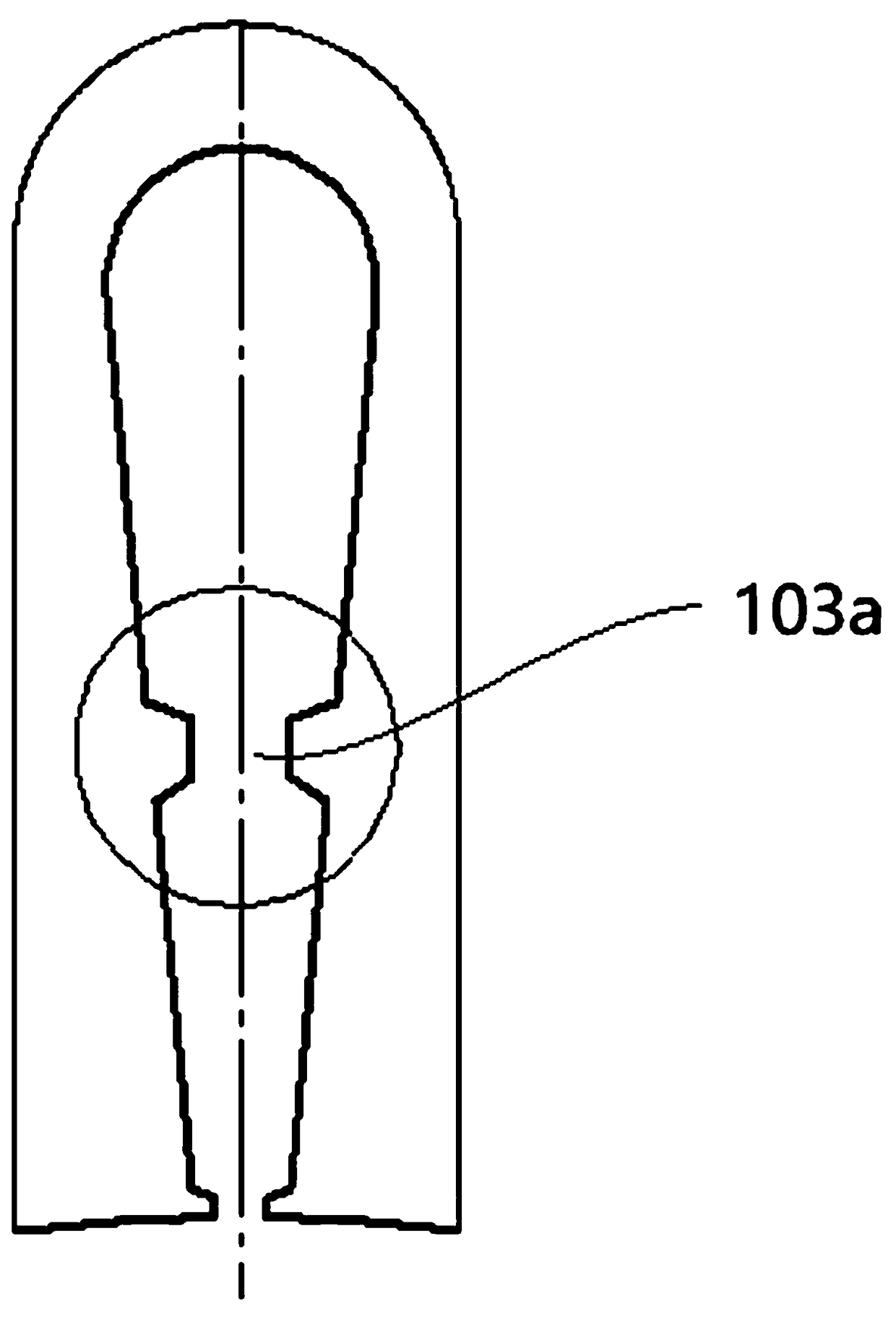

[0028] In order to facilitate processing and manufacturing, such as image 3 As shown, the vent 103 is a trapezoidal vent 103a. The shape is widely used, the processing and manufacturing technology is mature, and the dimensional stability is good during processing.

[0029] Such as Figure 4-5 As shown, in this example, the vent 103 can also be a circular vent 103b or a rectangular vent 103c.

[0030] For the convenience of processing, the outer circumference of the stator punching piece is circular, and the inner side of the inner slot 102 is opened. It conforms to the structural characteristics of the stator sheet punching of the frequency conversion and ca...

example 2

[0036] The difference from the above example is that the windings of the outer slots 101 are only arranged in some of the outer slots 101 , and the other part of the outer slots 101 are empty. Part of the outer tank 101 is left empty to form a larger ventilation channel, which has a better ventilation effect, can better reduce the temperature rise of the motor, improve the capacity increase capacity of the variable frequency motor, and increase the load capacity.

[0037] In actual application, after adopting the design change of the present invention, the temperature rise is reduced by about 8%, and the cost is reduced by 20%-30% at the same time, and the motor capacity can be increased by 1-2 gears.

[0038] above Figure 1-5 The shown one kind of variable frequency capacity increasing motor stator punching, stator and stator winding embedding method is a specific embodiment of the present invention, which has already reflected the substantive characteristics and progress of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com