IGBT multi-parallel module driving circuit

A drive circuit, parallel technology, applied in the direction of electrical components, output power conversion devices, etc., can solve problems such as common emitter circulation, circuit balance, etc., achieve the effect of reducing fault points, simple circuit design, and satisfying the synchronous operation of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

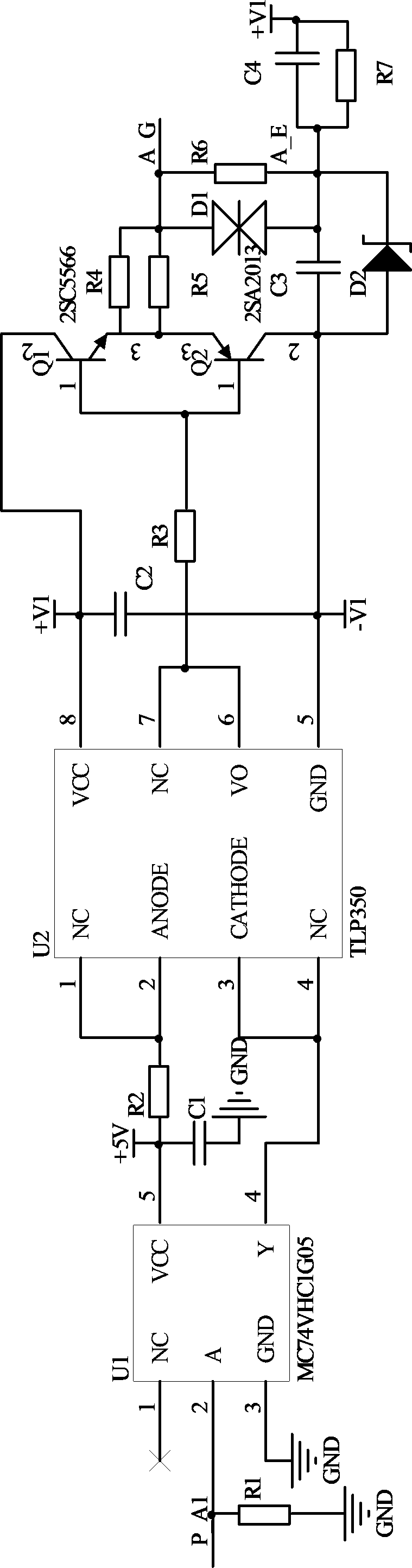

[0018] Such as figure 1 As shown, the IGBT multi-parallel module drive circuit described in this embodiment is composed of multiple IGBT single-module drive circuits connected in parallel. The IGBT single-module drive circuit includes:

[0019] Inverter open-drain output module U1; optocoupler U2; resistor R1, resistor R2, resistor R3, resistor R4, resistor R5, resistor R6, resistor R7; non-polar capacitor C1, non-polar capacitor C2, non-polar capacitor C3, Non-polar capacitor C4; NPN transistor silicon transistor Q1, PNP transistor silicon transistor Q2; bidirectional regulator D1; voltage regulator diode D2;

[0020] One end of the resistor R1 is connected to pin 2 of the open-drain output module U1 of the inverter; pin 5 of the open-drain output module U1 of the inverter is connected to one end of the resistor R2 and one end of the non-polar capacitor C1, and the other end of the resistor R2 , Pin 1 of optocoupler U2 and pin 2 of optocoupler U2 are connected together; pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com