Image collecting system of water chamber environment of steam generator

A steam generator and environmental image technology, applied in image communication, closed-circuit television system, TV system components, etc., can solve the problem that the error of the transmission mechanism of the steam generator cannot be completely eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

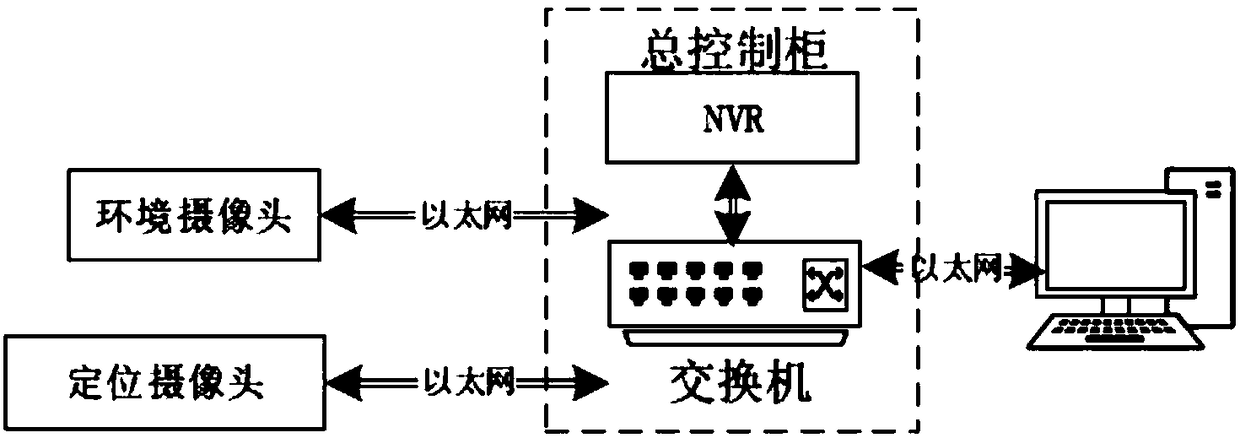

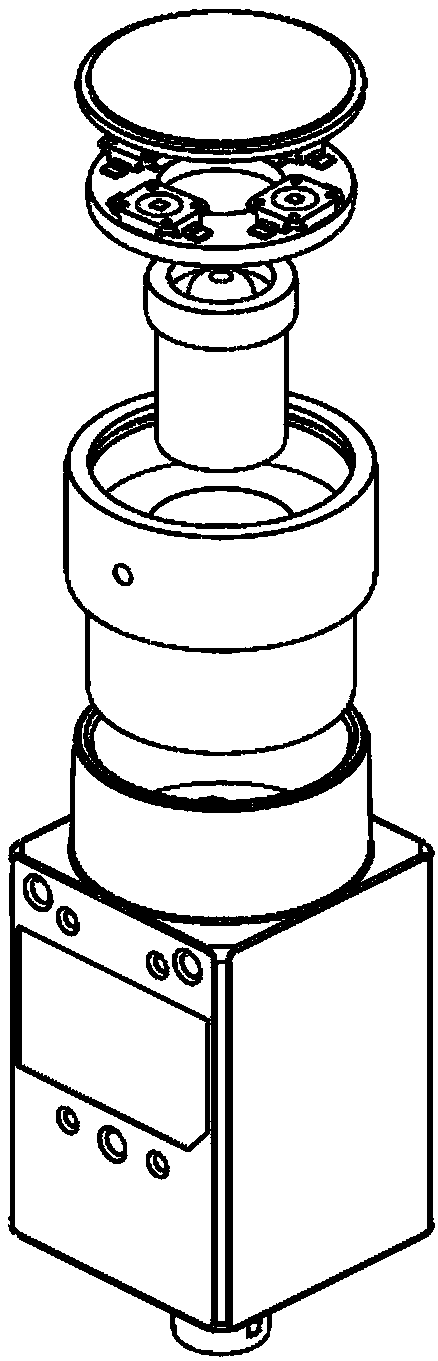

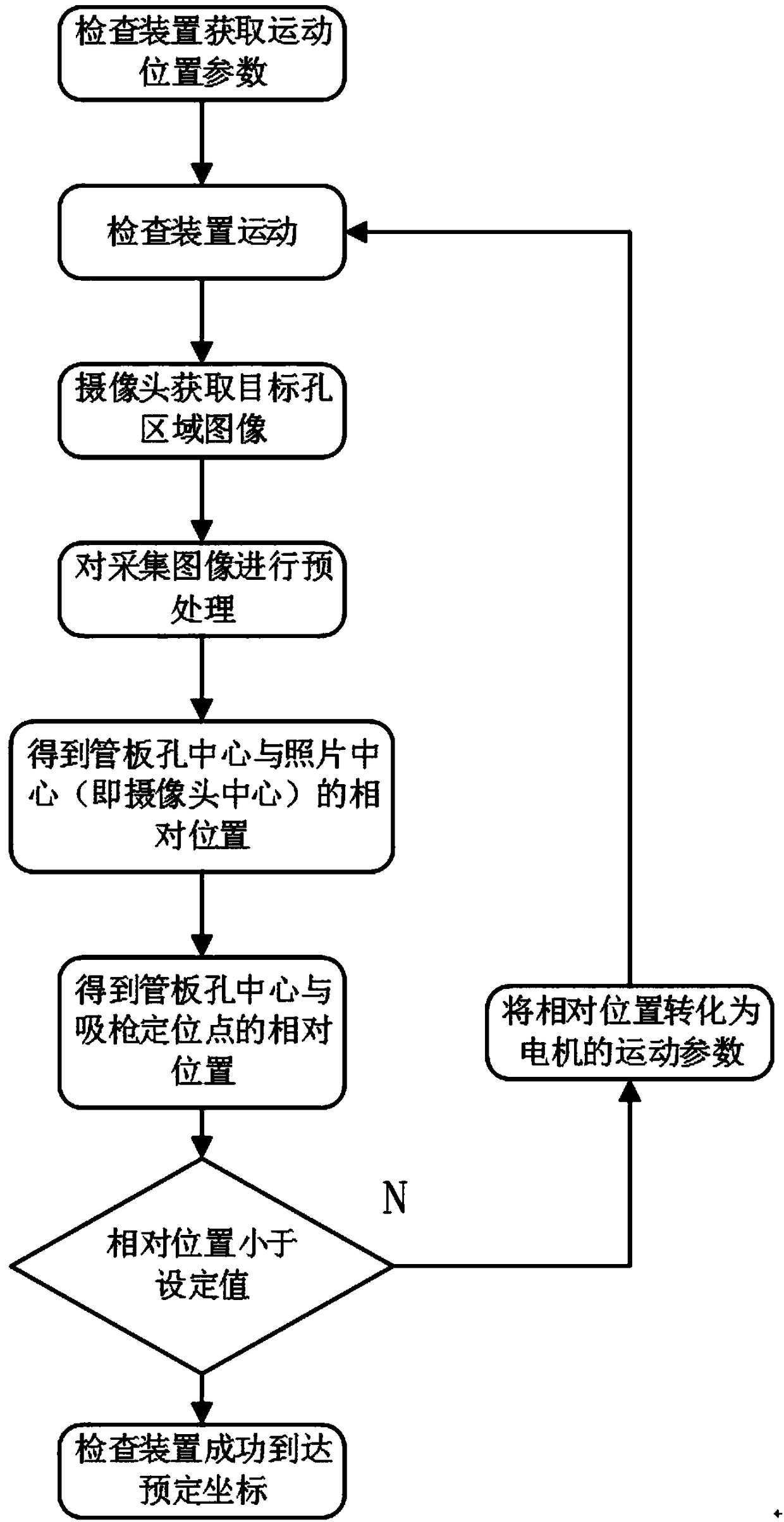

[0027] Such as Figure 1 to Figure 5 As shown, a steam generator water chamber environment image acquisition system, including the environment camera 1, positioning camera 2, switch and industrial computer, the camera transmits the video signal to the host computer through the network switch, so as to realize the internal There are two functions of image acquisition and video image precision control. The internal image acquisition of the water chamber mainly collects the environmental image of the water chamber and the overall status of the maintenance equipment through the environmental camera, so as to avoid the collision between the inspection device 3 and the internal structure of the steam generator such as the inner wall of the water chamber 4, the heat transfer tube 5 or the throttling component 6; video Image precision control is to collect ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com