Pipe chain type conveyor and chain transmission device used by same

A conveyor and chain drive technology, applied in conveyors, transportation and packaging, loading/unloading, etc., can solve the problems of loud noise and easy production of metal powder, achieve low noise, avoid direct contact, and avoid metal debris pollution Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

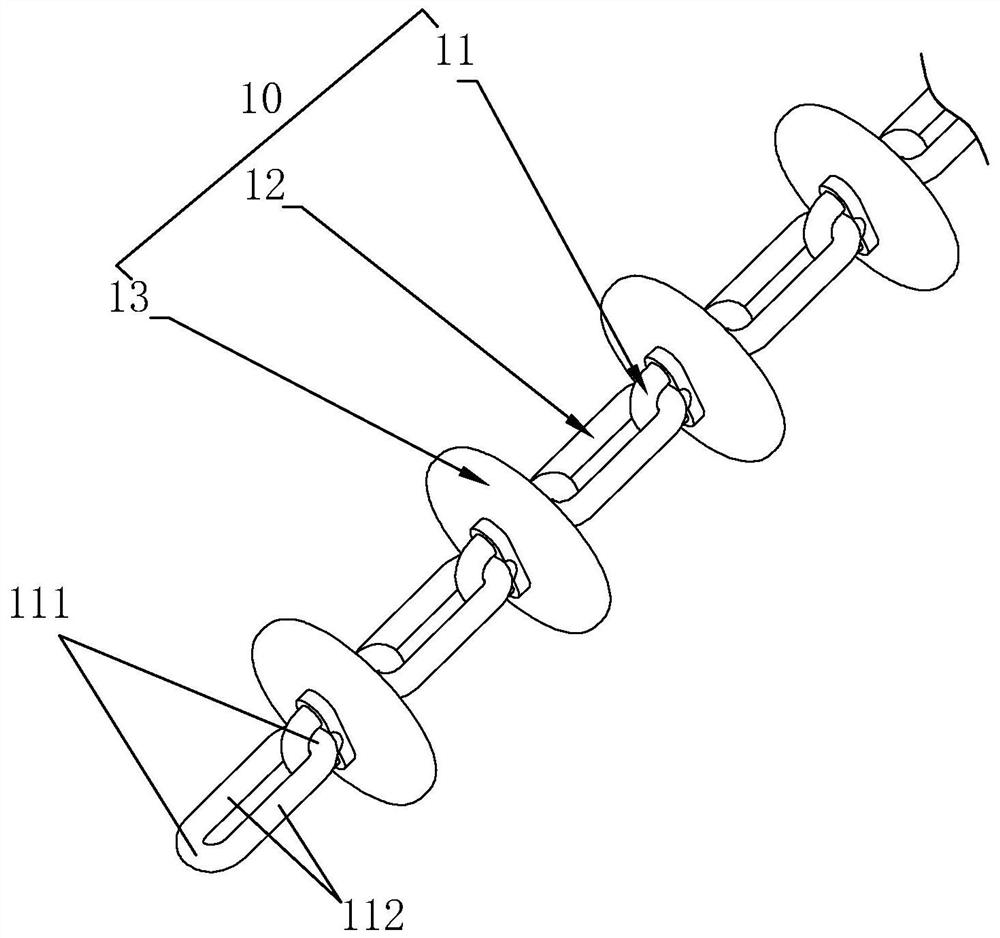

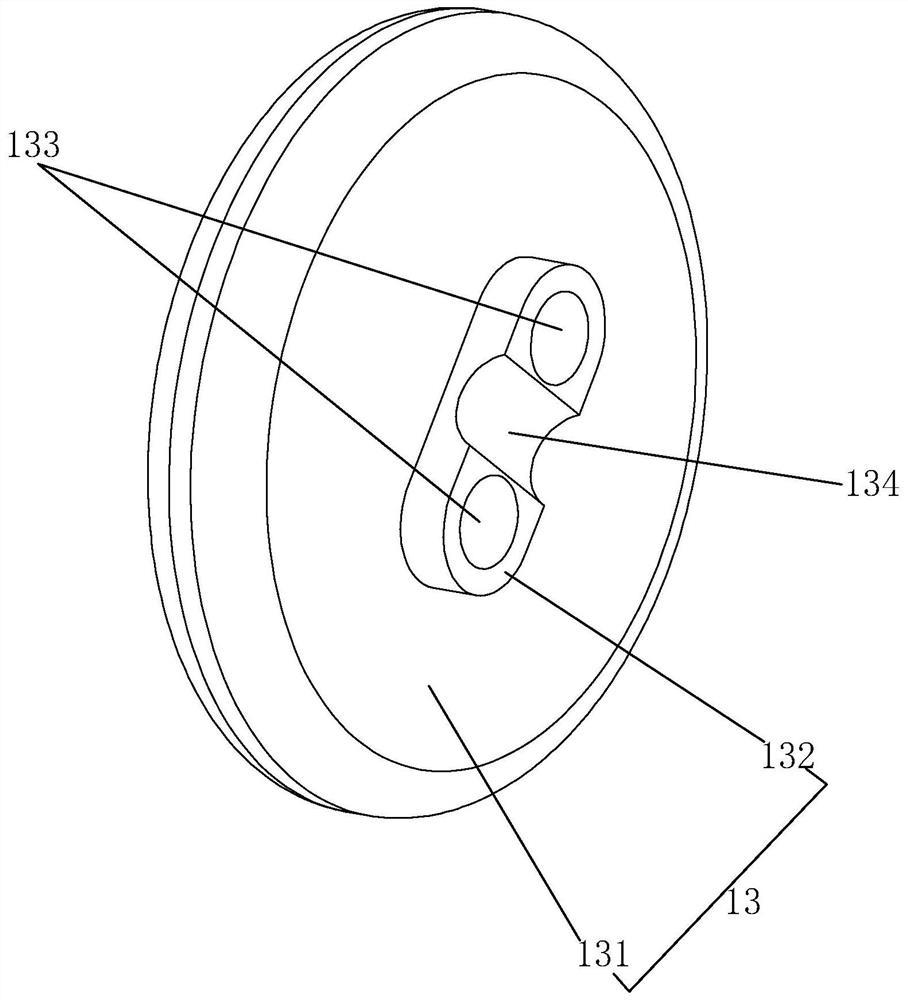

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. Since in the technical solution of the present invention, the conveyor chain is a flexible chain, it is difficult to maintain an ideal posture during the transmission process. Therefore, the position and posture of the chain pieces in the solution of the present invention are ideal positions and postures, It embodies the design concept of the present invention. During actual use, the position and posture of the chain pieces will change. The technical solution of this application does not describe the situation after the posture changes one by one.

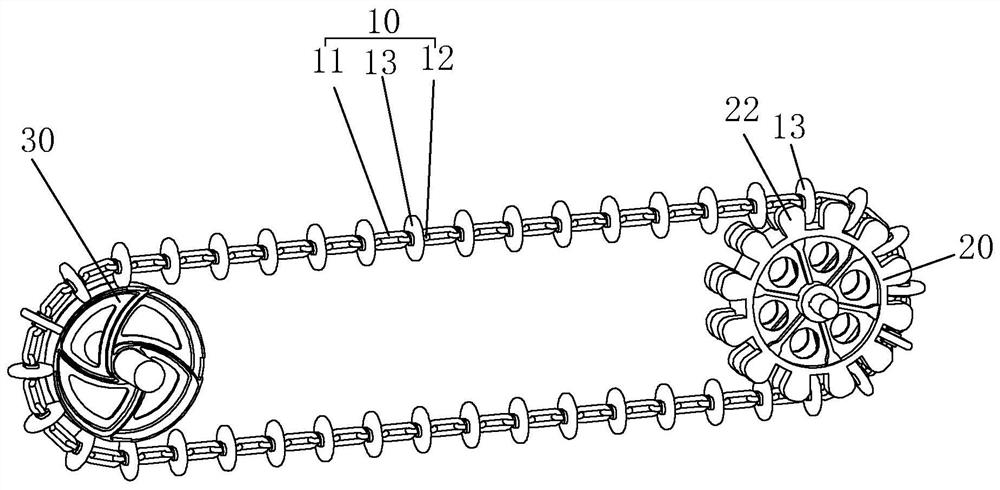

[0037] A chain drive, such as figure 1 As shown, it includes a conveyor chain 10 , a driving sprocket 20 , a driven sprocket 30 and a driving device (not shown) for driving the driving sprocket 20 to rotate. The conveyor chain 10 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com