Technology applied to printed circuit board of electric power supply

A printed circuit board, printed circuit technology, applied in the direction of laminated printed circuit boards, printed circuits, printed circuit manufacturing, etc. It can reduce the drilling time, uniform force, and reduce layer migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

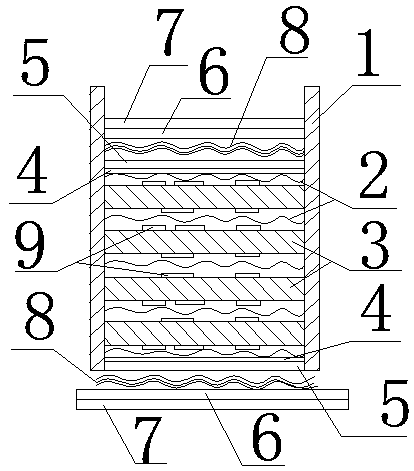

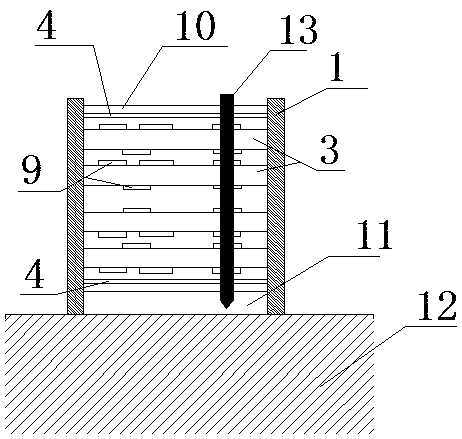

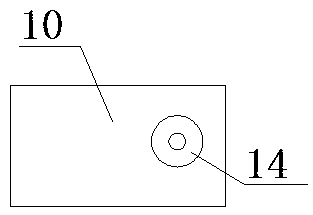

[0038] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0039] Such as Figure 1~4 As shown, in this embodiment, the rectangular vertical container 1 is an aluminum rectangular hollow column with openings at both ends, and the length and width of the inner wall of the rectangular hollow column are consistent with the size of the combined circuit board;

[0040] S1. Cutting: cutting out the prepreg 2, the inner layer board 3 and the copper foil 4, so that the length and width of the prepreg 2, the inner layer board 3 and the copper foil 4 are all the same;

[0041] S2. Inner layer graphics: obtain printed circuit graphics on the inner layer board 3 through graphic transfer technology;

[0042] S3. Inner layer etching: the inner layer board 3 with the printed circuit 9 is obtained by etching;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com