Shell and meat separation device for aquatic product processing

A technology for shell and meat separation and aquatic products, which is applied in the field of shell and meat separation devices for processing aquatic products, can solve the problems of lower production efficiency, lower clam meat quality, lower product quality, etc., and achieve the effect of reasonable design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

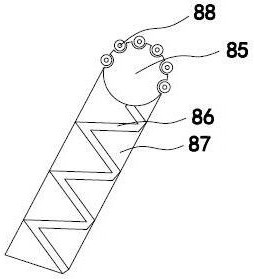

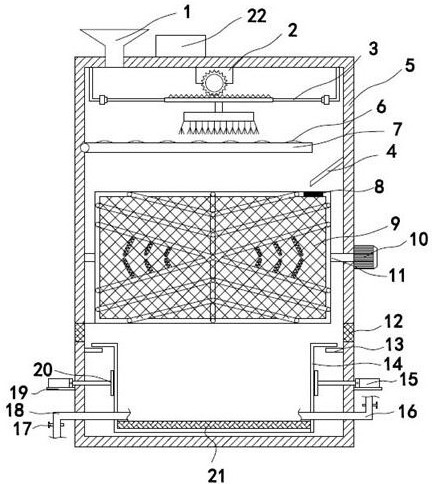

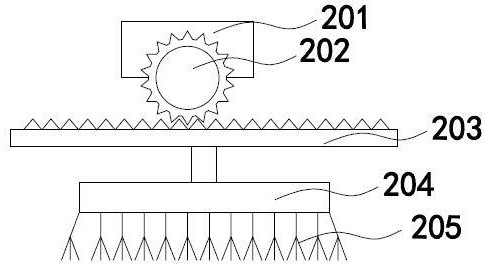

[0021] like Figure 1-5 As shown in the figure, the shell and meat separation device for aquatic product processing includes a box body 5. The inside of the box body 5 is sequentially provided with a cleaning device 2, a drum 8, and a cleaning cavity 14 from top to bottom. Hopper 1, the right side of the feeding hopper 1 is provided with one end of the L-shaped telescopic rod 3 connected to the upper two sides of the inside of the box 5, the other end of the L-shaped telescopic rod 3 is connected to the cleaning device 2, and a support plate is provided below the cleaning device 2 7. The left side of the support plate 7 is connected to the side wall of the box body 5. A number of decontamination blocks 6 are arranged above the support plate 7. The surface of the decontamination blocks 6 is adhered with abrasive particles 62, and the decontamination blocks 6 are provided with grooves 61. The device can deeply clean the shell of the clams, and the cleaned clams will be discharge...

Embodiment 2

[0029] like Figure 1-5 Shown: In the actual use of the shell and meat separation device for aquatic product processing, put clams from the feeding hopper 1, the clams will be scattered on the support plate 7, start the cleaning device 2, and the cleaning device 2 The clam case will be cleaned back and forth, and the decontamination block 6 on the support plate 7 can play an auxiliary role in cleaning, and can also increase the friction with the clam shell. After the cleaning is completed, the support plate 7 will Rotate down a certain angle, the clams will slide along the downwardly inclined support plate 7 to the guide plate 4, and then the guide plate 4 will send the clams into the drum 8, and the drum 8 is driven by the motor 10 to rotate rapidly. Due to the action of centrifugal force and gravity, the clams will hit the inclined guide rod 83 and the elastic member 84 during the falling process, and this process will be repeated to realize the separation of the shell and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com