Mesoporous nano platinum-nickel oxygen reduction electrocatalyst and preparation method thereof

An electrocatalyst, nano-platinum technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of difficult synthesis of regular morphology and size, etc. Achieve the effect of enhancing catalytic activity and stability, highlighting activity and stability, and high application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of mesoporous platinum-nickel nanoparticles oxygen reduction electrocatalyst, said method comprising the steps of:

[0038] (1) prepare the chloroplatinic acid and the nickel chloride solution that concentration is 20mM respectively, the ascorbic acid solution that concentration is 0.1M;

[0039] (2) Dissolve 30mg of F127 and 0.2g of potassium bromide in 1.25mL of water;

[0040] (3) Mix 1.125mL of chloroplatinic acid solution, 0.375mL of nickel chloride solution, 2mL of ascorbic acid solution and the solution of step (2), place in a water bath at 70°C for 12 hours, after the reaction is complete, centrifuge and wash The mesoporous platinum-nickel nanoparticle is obtained, and the product is dried at 50° C. for 12 hours to obtain the mesoporous platinum-nickel nanoparticle oxygen reduction electrocatalyst.

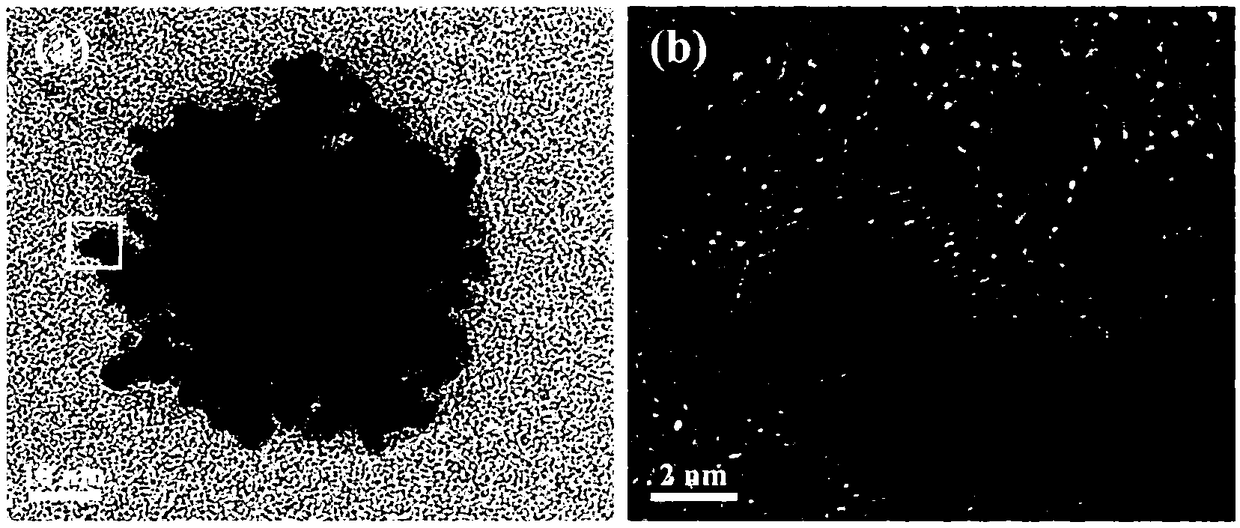

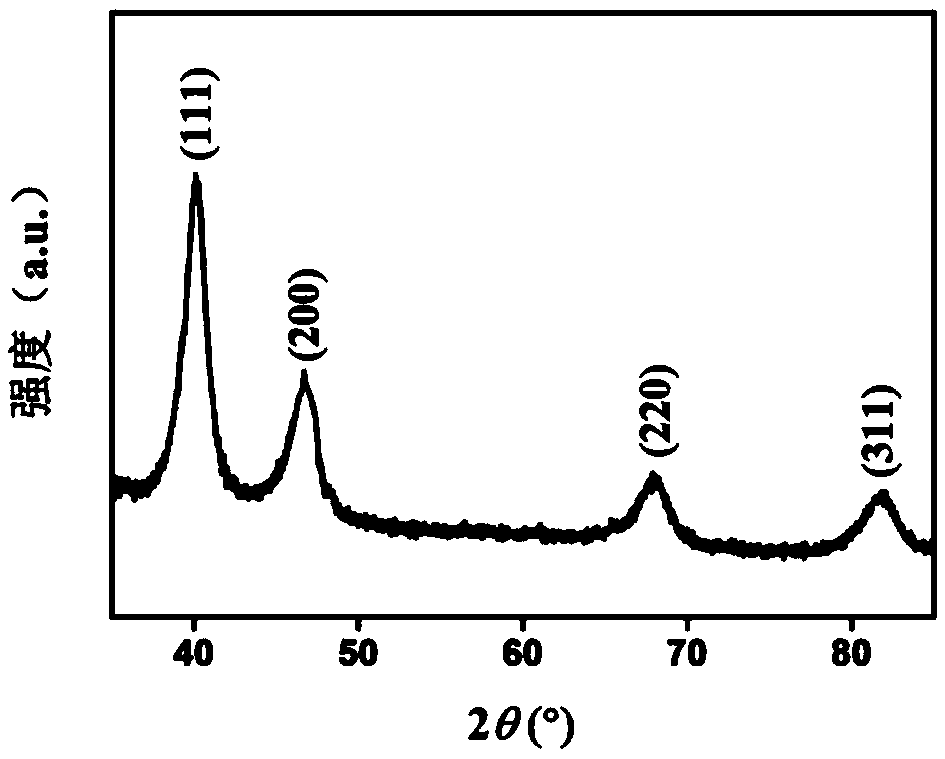

[0041] The SEM image of the obtained mesoporous platinum-nickel nanoparticles is shown in figure 1 . The TEM and HRTEM images of the obtaine...

Embodiment 2

[0044] A method for preparing mesoporous platinum nanoparticles oxygen reduction electrocatalyst, said method comprising the steps of:

[0045] (1) prepare the chloroplatinic acid solution that concentration is 20mM respectively, the ascorbic acid solution that concentration is 0.1M;

[0046] (2) Dissolve 30mg of F127 and 0.2g of potassium bromide in 1.25mL of water;

[0047] (3) The chloroplatinic acid solution of 1.5mL, the ascorbic acid solution of 2mL and the solution of step (2) were mixed, placed in a water bath of 70° C. for 12 hours, and the reaction was completed, centrifuged and washed to obtain mesoporous platinum-nickel nanoparticles, The product was dried at 50°C for 12 hours to obtain a mesoporous platinum-nickel nanoparticle oxygen reduction electrocatalyst.

[0048] The SEM image of the obtained mesoporous platinum nanoparticles can be found in Figure 8 , the linear sweep voltammetry and Tafel slope of the obtained mesoporous platinum nanoparticles at 1600 r...

Embodiment 3

[0051] A preparation method of mesoporous platinum-nickel nanoparticles oxygen reduction electrocatalyst, said method comprising the steps of:

[0052] (1) prepare the chloroplatinic acid and the nickel chloride solution that concentration is 40mM respectively, concentration is the ascorbic acid solution of 0.1M;

[0053] (2) Dissolve 30mg of F127 and 0.2g of potassium bromide in 1.25mL of water;

[0054] (3) Mix 1.125mL of chloroplatinic acid solution, 0.375mL of nickel chloride solution, 2mL of ascorbic acid solution and the solution of step (2), place in a water bath at 70°C for 12 hours, after the reaction is complete, centrifuge and wash The mesoporous platinum-nickel nanoparticles are obtained, and the product is dried at 40° C. for 10 hours to obtain the mesoporous platinum-nickel nanoparticles oxygen reduction electrocatalyst.

[0055] In this synthesis process, the concentration of chloroplatinic acid and nickel chloride solution is too high, the reaction rate is too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com