Electric-controlled wind power processing device

A technology of electrical control and processing equipment, which is applied in the direction of driving devices, manufacturing tools, metal processing equipment, etc., and can solve the problems that it is inconvenient for the staff to clean up and process the fly cutting, cannot improve the machining accuracy of the staff, and cannot prevent the mutual interference of the motors, etc. , to achieve the effect of reducing the round jump of the tail end, reducing the loss rate of the equipment, and preventing burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

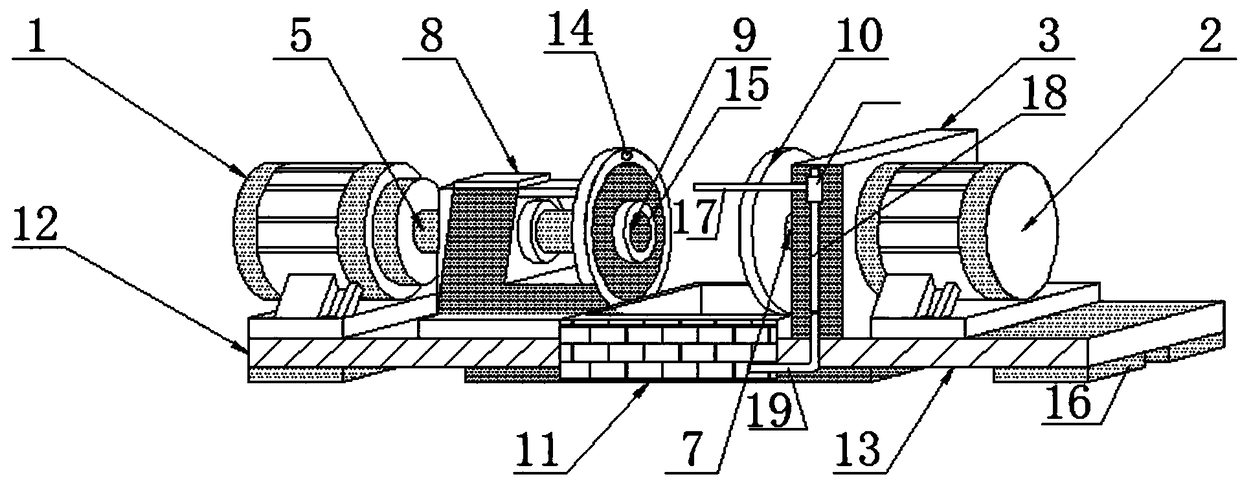

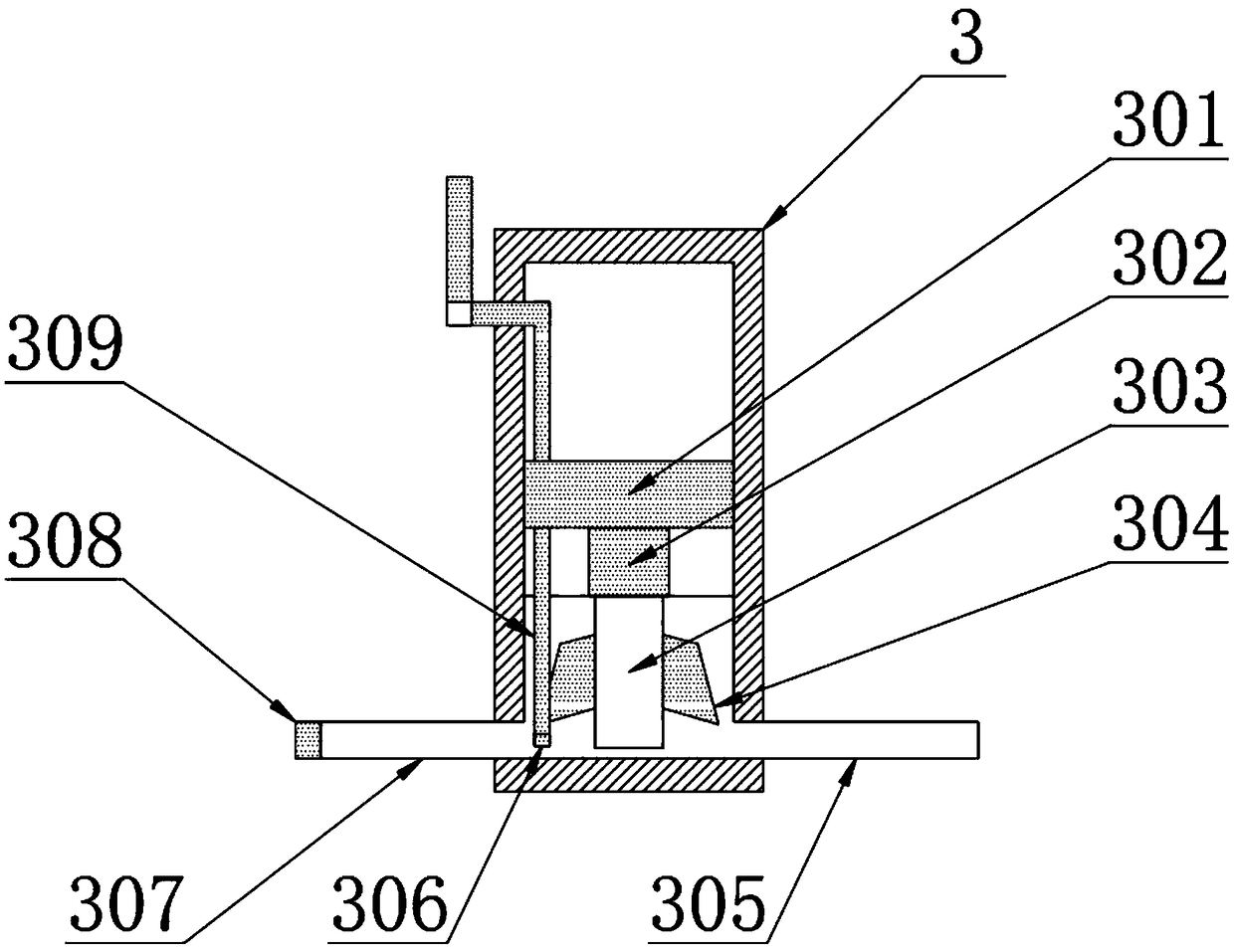

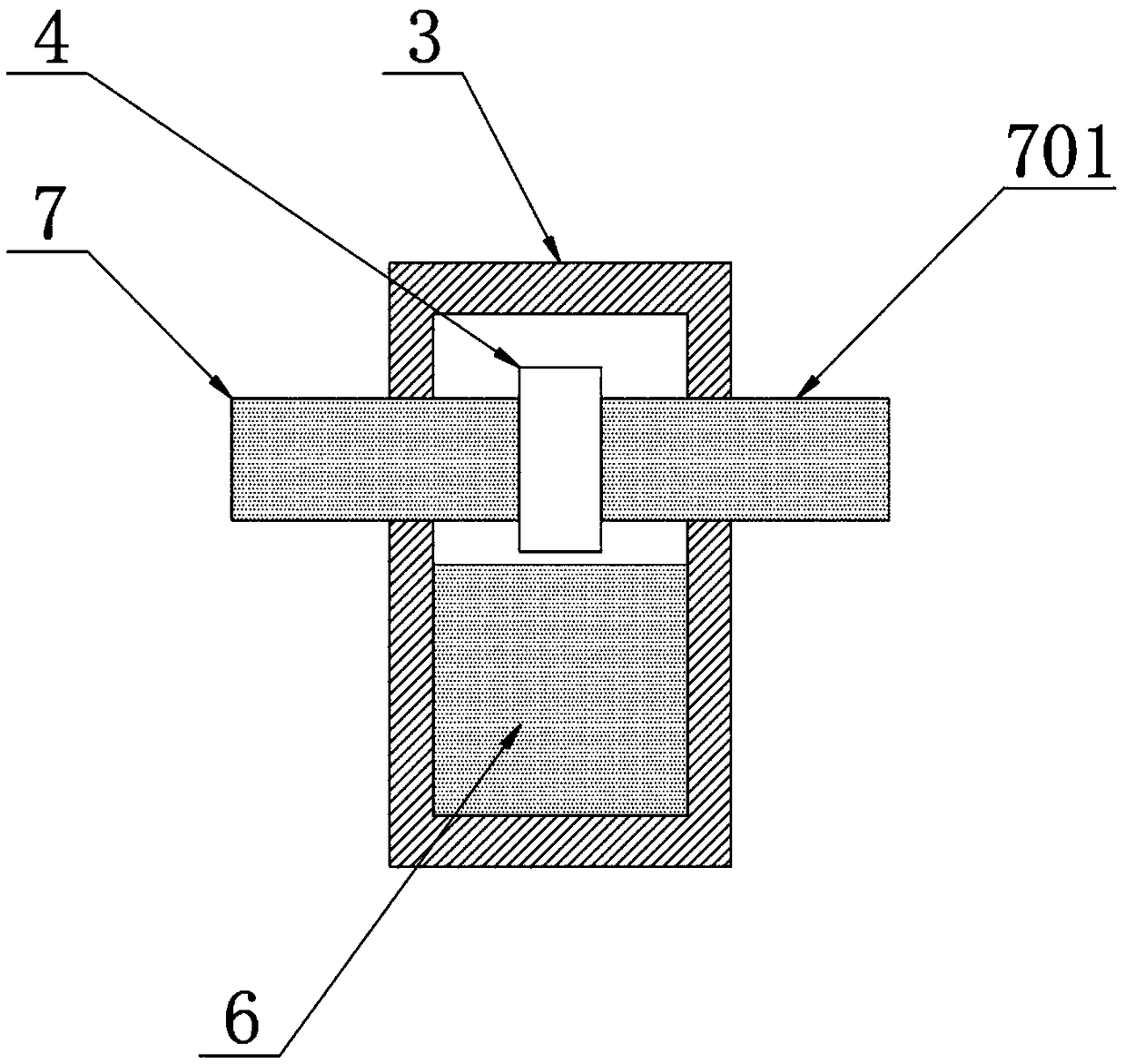

[0032] see Figure 1~6 , in an embodiment of the present invention, an electrically controlled wind power processing device includes a first motor 1, a second motor 2 and a controller, the output end of the first motor 1 is connected to the first device through a one-way clutch transmission assembly 4 Clamping surface 9, the output end of the second motor 2 is connected to the second clamping surface 10 through the one-way clutch transmission assembly 4, the first clamping surface 9 is arranged opposite to the second clamping surface 10, and the The central axes of the first clamping surface 9 and the second clamping surface 10 are on a straight line, and the two ends of the wind power component to be processed are clamped and fixed on the first clamping surface 9 and the second clamping surface 10 respectively. On the clamping surface 10, it is characterized in that,

[0033] The one-way clutch transmission assembly 4 only allows the first motor 1 to transmit torque to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com