Diamond string bead wire saw

A technology of diamond beading and diamond wire saw, which is applied in the direction of stone processing equipment, working accessories, fine working devices, etc., can solve the problems of difficult transportation and installation, high requirements for frame structure stability, and reduced safety factor, so as to facilitate processing Manufacture, transportation and installation, improve multi-standard adaptability, and high balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

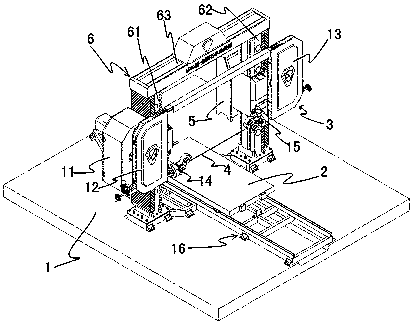

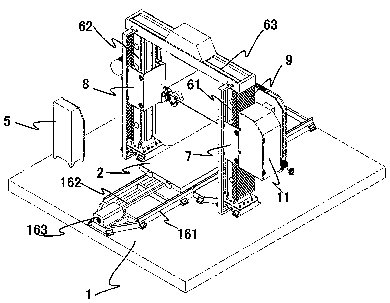

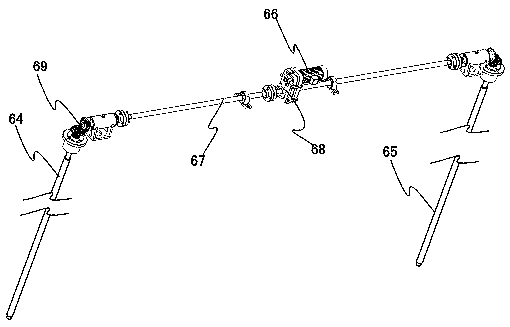

[0035] refer to Figure 1 to Figure 10 , the embodiment of the present invention discloses that a diamond beaded wire saw machine includes a frame 1, a workbench 2, a flywheel drive device 3, a diamond wire saw 4 and an electrical control console 5; the frame 1 includes a fixed base , the fixed base is provided with a vertical lifting frame 6, and the vertical lifting frame 6 includes a left column 61 and a right column 62 symmetrically distributed, and a connection is provided between the top of the left column 61 and the top of the right column 62. Bridge 63, a side of the left column 61 and a side of the right column 62 are respectively provided with a rotatable left lifting screw mandrel 64 and a right lifting screw mandrel 65, and the connecting bridge 63 is provided with a lifting drive motor 66 and a horizontal Transmission shaft 67, the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com