Treatment system for heavy metal wastewater

A waste water treatment system, heavy metal technology, applied in the direction of water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of uneven particle size of activated carbon, low efficiency of activated carbon crushing, etc. Uniformity, innovative design, and efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

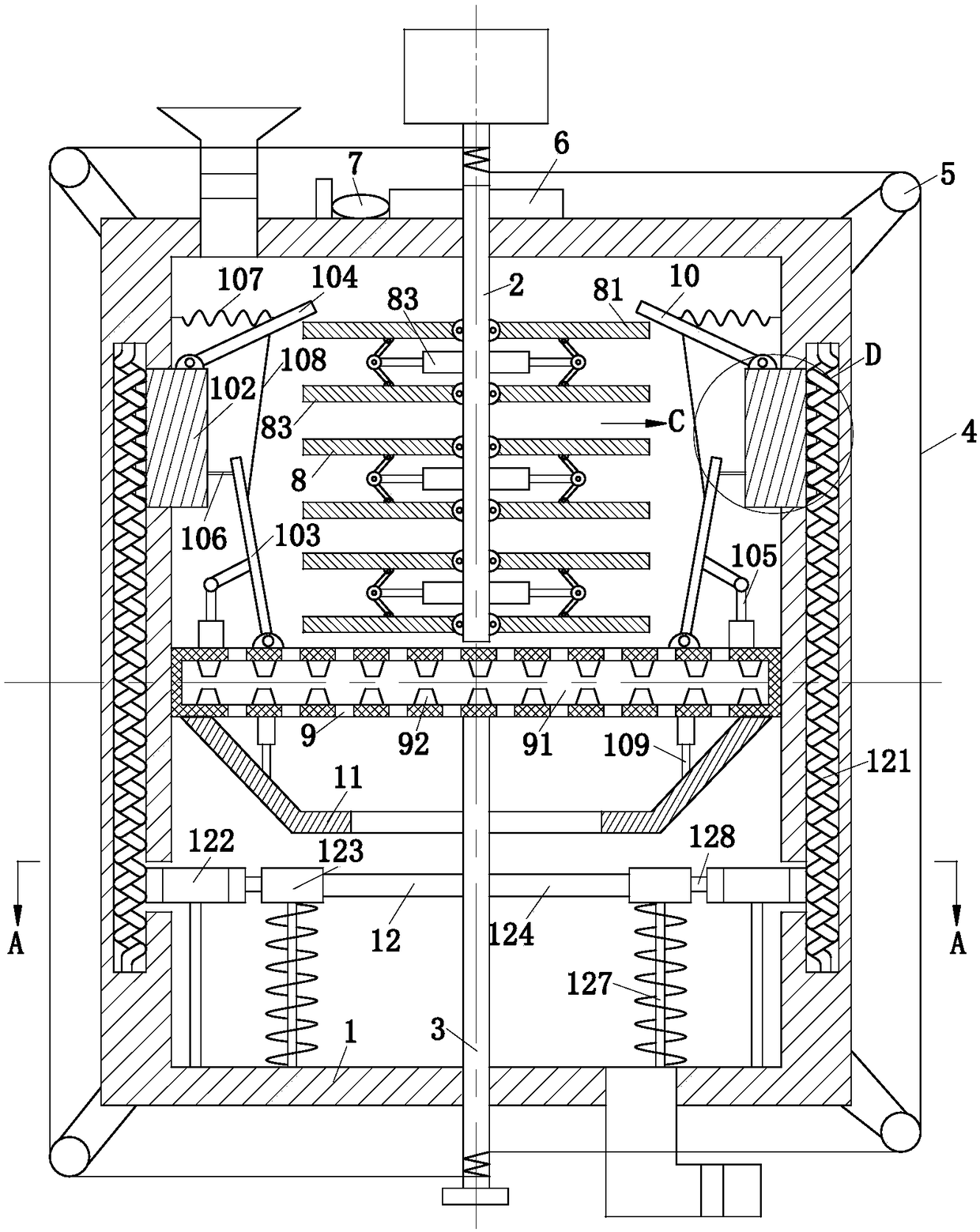

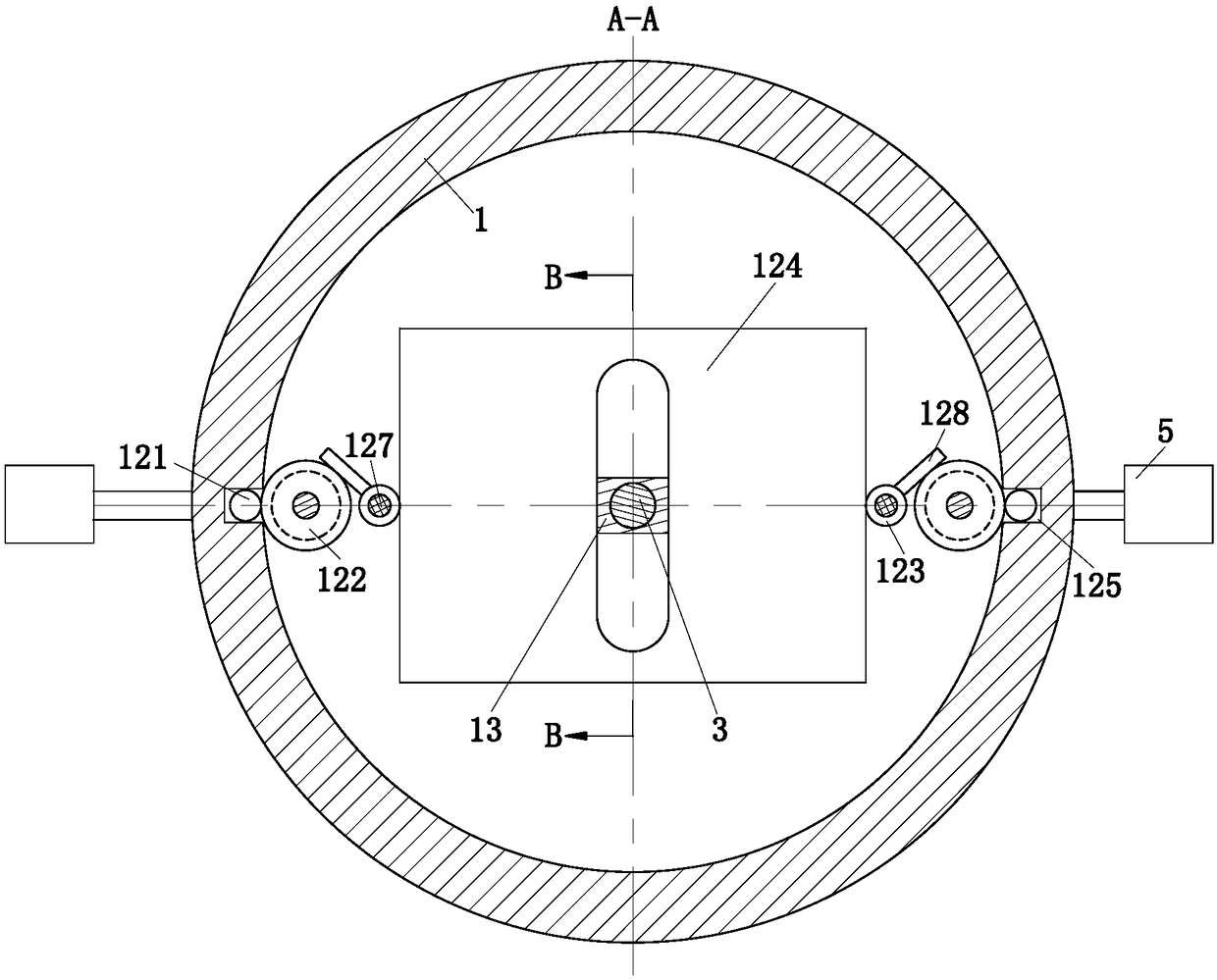

[0033] As a specific embodiment of the present invention, a filter unit 12 is provided below the guide ring 11, and the filter unit 12 is used to filter the activated carbon again; the filter unit 12 includes a No. 2 spring 121, a gear 122, a rotating The wheel 123 and the filter screen 124; the side wall of the working chamber 1 is provided with a No. 2 hollow cavity 125, the No. 2 hollow cavity 125 is located outside the chute 101, and the side above the No. The chute 101 is connected, the side below the No. 2 hollow cavity 125 is provided with an opening, and the side of the slider 102 away from the elastic cloth 106 is fixed with a conical convex tooth 126; the No. 2 spring 121 is located in the No. 2 hollow cavity body 125, and the end of the No. 2 spring 121 is rotatably connected to the No. 2 hollow cavity 125; the conical protruding teeth 126 are located between the adjacent spring coils of the No. 2 spring 121 and are in contact with the No. 2 spring 121, the cone The...

specific Embodiment approach

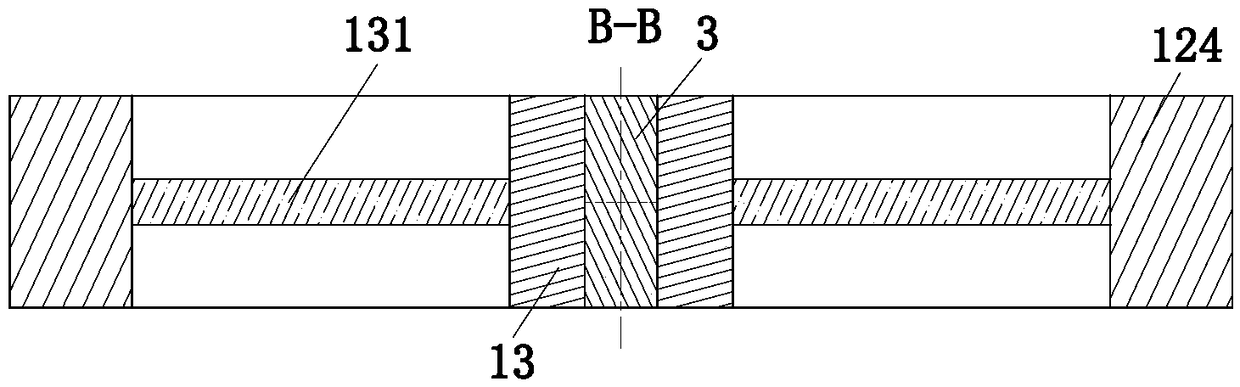

[0034] As a specific embodiment of the present invention, the part of the No. 2 rotating rod 3 located in the through hole of the filter screen 124 is sleeved with a slip ring 13, an elastic film 131 is arranged between the slip ring 13 and the through hole, and the elastic film 131 One end is fixedly connected with the slip ring 13, and the other end is fixedly connected with the through hole; in the present invention, by setting the slip ring 13 and the elastic film 131, when the filter screen 124 moves up and down in the horizontal direction, the elastic film 131 is stretched and blocked The gap between the slip ring 13 and the through hole prevents the activated carbon from falling out of the through hole of the filter screen 124, resulting in poor filtration of the activated carbon.

[0035] When the activated carbon falls from the filter ring 9, it enters into the guide ring 11. The guide ring 11 is used to receive the pulverized activated carbon particles to prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com