Hole transport material and quantum dot light emitting diode

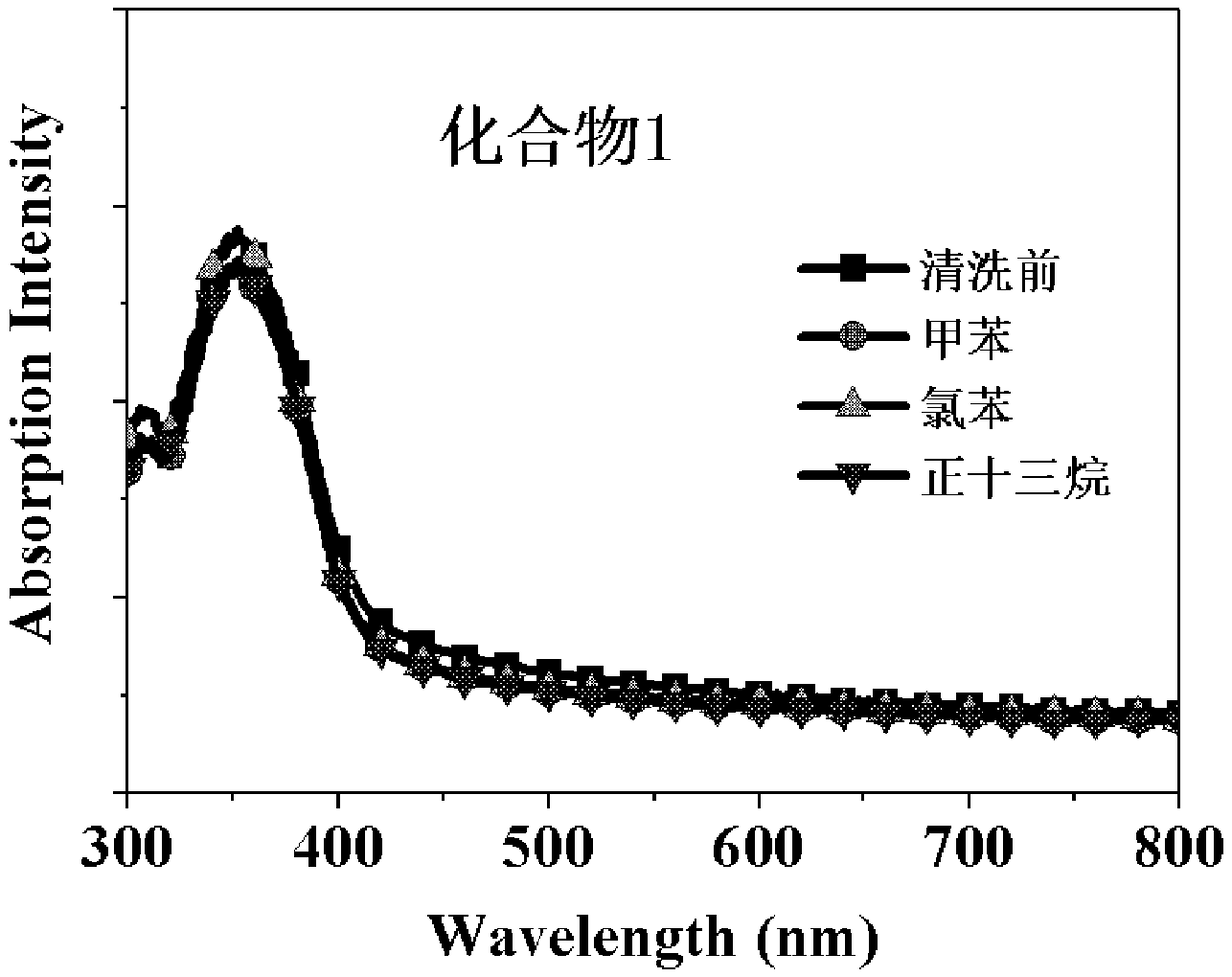

A hole-transporting material and quantum dot light-emitting technology, applied in electrical components, circuits, organic chemistry, etc., can solve the problems of low material utilization, high cost, poor product yield, etc., to achieve high interface stability and improve efficiency. and longevity, the effect of 100% solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

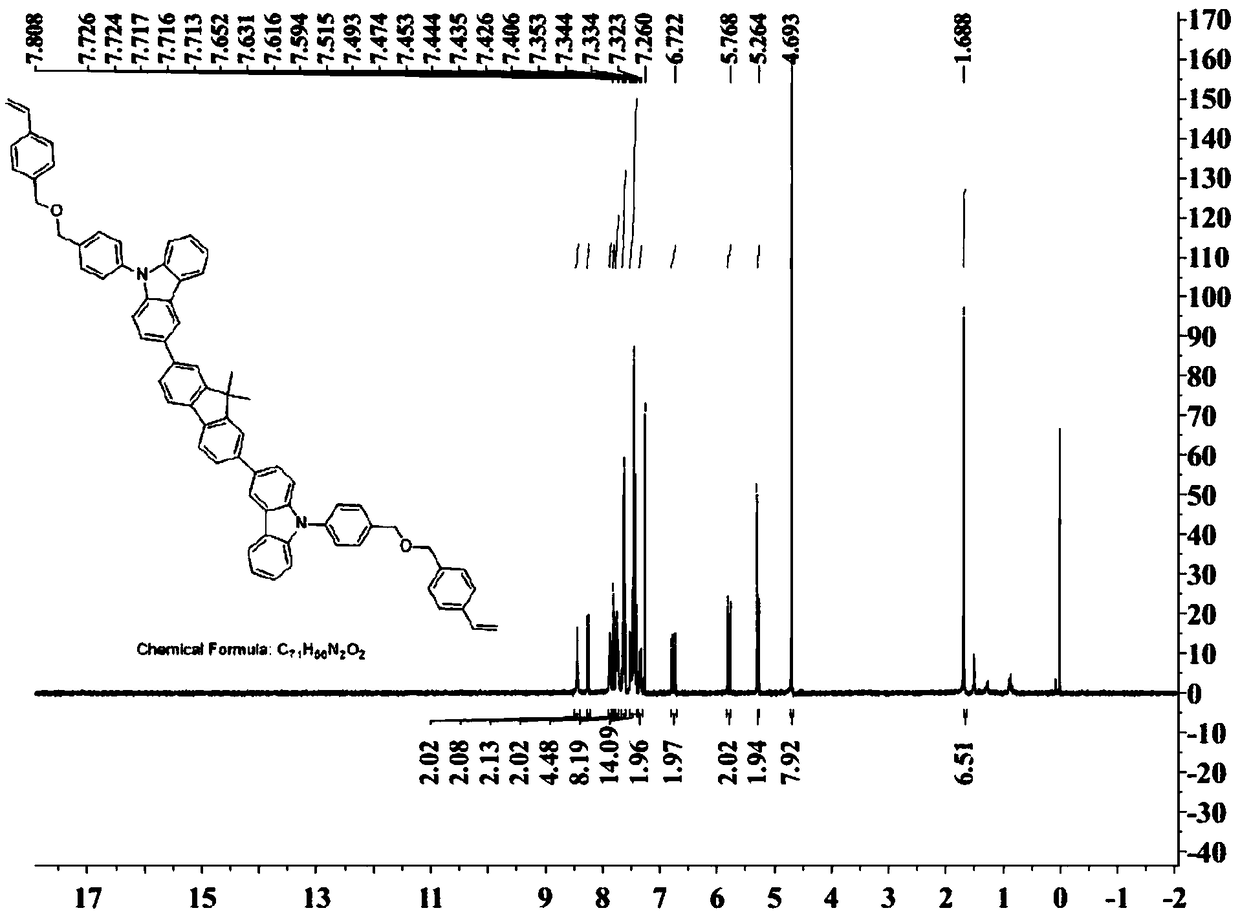

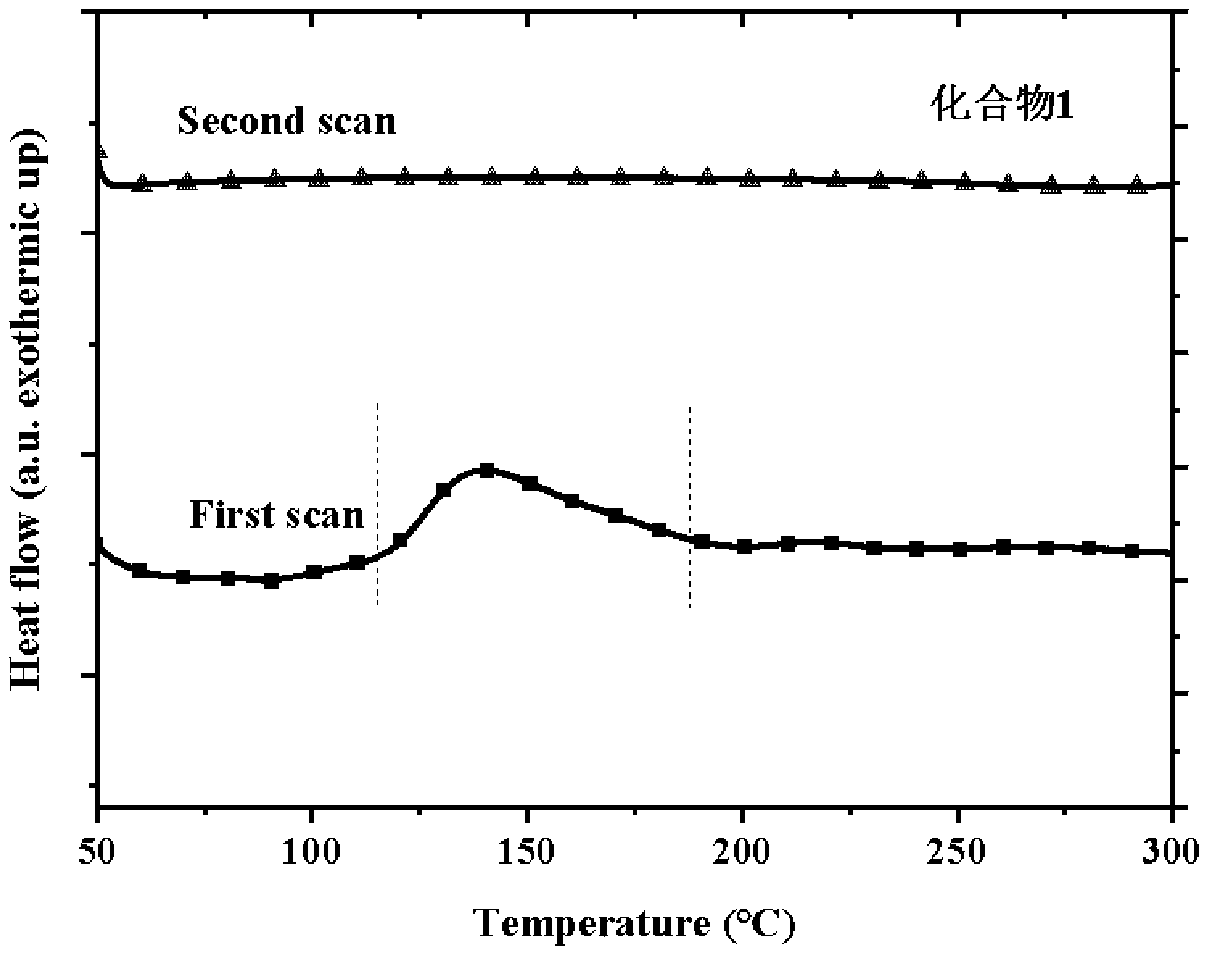

[0032] Embodiment 1: the synthesis of compound 1

[0033] Material 1 (SM-1) and 3 equivalents of base (NaOH) were dissolved in an appropriate amount of DMF (N,N-dimethylformamide), and replaced with nitrogen three times. Then weigh 3 equivalents of material 2 (SM-2) and dissolve it in an appropriate amount of DMF, add it dropwise to the above solution at room temperature under the protection of nitrogen, and stir the reaction overnight. After the reaction, the reaction solution was poured into water to precipitate a white solid, and the obtained solid was fully washed with water and alkaline solution to obtain the target product 1, the yield: 85%, elemental analysis: C, 87.95%; H, 5.80%; N, 2.87% (measured value); C, 87.98; H, 5.82; N, 2.89 (C 71 h 56 N 2 o 2 Theoretical value), hydrogen spectrum such as figure 1 shown.

[0034] Synthetic route 1:

[0035]

Embodiment 2

[0036] Embodiment 2: the synthesis of compound 2

[0037] Material 3 (SM-3) and 3 equivalents of base (KOH) were dissolved in an appropriate amount of DMF, and replaced with nitrogen three times. Then weigh 3 equivalents of material 2 (SM-2) and dissolve it in an appropriate amount of DMF, add it dropwise to the above solution at room temperature under the protection of nitrogen, and stir the reaction overnight. After the reaction, the reaction solution was poured into water to precipitate a white solid, and the obtained solid was fully washed with water and lye to obtain the target product 2, the yield: 90%, elemental analysis: C, 87.65%; H, 6.87%; N, 2.49% (measured value); C, 87.69; H, 6.90; N, 2.52 (C 81 h 76 N 2 o 2 theoretical value).

[0038] Synthetic route 2:

[0039]

Embodiment 3

[0040] Embodiment 3: the synthesis of compound 3

[0041] Material 4 (SM-4) and 3 equivalents of base (NaH) were dissolved in an appropriate amount of DMF, and replaced with nitrogen three times. Then weigh 3 equivalents of raw material 2 (SM-2) and dissolve it in an appropriate amount of DMF, and add it dropwise to the above solution under the protection of nitrogen at room temperature, and stir the reaction overnight. After the reaction, the reaction solution was poured into water to precipitate a white solid, and the obtained solid was fully washed with water and lye to obtain the target product 3, the yield: 60%, elemental analysis: C, 87.60%; H, 7.25%; N, 2.41% (measured value); C, 87.59; H, 7.26; N, 2.40; (C 85 h 84 N 2 o 2 theoretical value).

[0042] Synthetic route 3:

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com