Manufacturing method for controlling large inclusion of non-quenched and tempered steel

A non-quenched and tempered steel, large-scale technology, applied in the field of smelting and manufacturing controlled by large-scale inclusions, can solve the problems of poor pourability of molten steel, affecting production efficiency, and stopping pouring, ensuring stable and smooth running, reducing Quantity, the effect of improving the fatigue life of the crankshaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described.

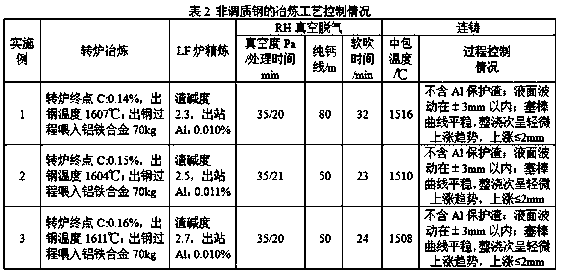

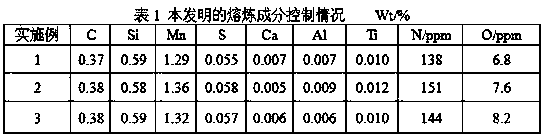

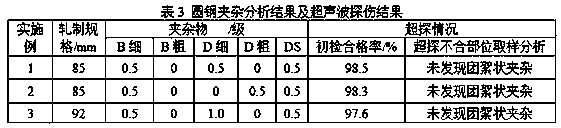

[0016] Adopt the chemical composition range described in the present invention, the main smelting chemical composition (wt%) of the embodiment 1,2,3 that manufactures is as shown in table 1; Take converter smelting, LF refining and RH refining and billet continuous casting, specifically The production process is shown in Table 2; the smelted steel billets were heated and rolled into 85mm-105mm round steel, and the horizontal hole 0.5mm×12.7mm was used for ultrasonic flaw detection, and the round steel was taken for inclusion analysis, ultrasonic The results of flaw detection and inclusion analysis are shown in Table 3.

[0017]

[0018]

[0019]

[0020] It can be seen from the examples that the steady-state control of the continuous casting process of the non-quenched and tempered steel with sulfur and nitrogen control produced by the present invention is adopted, and the round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com