Die-casting magnesium alloy and preparation method thereof

An alloy and casting magnesium technology, which is applied in the field of die-casting magnesium alloy and its preparation, can solve the problems that the mechanical properties of Mg-Al alloys, thermal conductivity and casting process performance cannot be taken into account.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Embodiments of the present invention also provide a method for preparing a die-casting magnesium alloy, which specifically includes the following steps:

[0050] S1: Weigh industrially pure Mg, pure Al, pure Zn ingots and Mg-Nd, Al-Mn master alloy ingots according to the corresponding weight percentage and the corresponding yield of each element;

[0051] S2: Melting, refining, cooling, deslagging and die-casting are carried out in sequence for each raw material.

[0052] Wherein, step S2 specifically includes:

[0053] S21: in CO 2 and SF 6 Under the protection of mixed gas, after the industrial pure Mg is melted, the temperature is raised to 720-750 °C, and the industrial pure Al, pure Zn ingot, Mg-Nd and Al-Mn master alloy are added to the melt every 2-10 minutes, and the Stir the melt several times to make the melt composition uniform.

[0054] It should be noted that it is preferable to heat up to 730°C after the industrial pure Mg is melted, and add industrial...

Embodiment 1

[0062] This embodiment provides a die-casting magnesium alloy, the weight percent of the alloy composition is: Al: 2.0%, Nd: 1.0%, Zn: 0.2%, Mn: 0.05%, and the balance is Mg, which is prepared by the following method :

[0063] S1: Weigh industrially pure Mg, pure Al, pure Zn ingots and Mg-Nd, Al-Mn master alloy ingots according to the corresponding weight percentage and the corresponding yield of each element;

[0064] S2: Melting, refining, cooling, deslagging and die-casting are carried out in sequence for each raw material.

[0065] Wherein, step S2 specifically includes:

[0066] S21: in CO 2 and SF 6 Under the protection of mixed gas, after the industrial pure Mg is melted, the temperature is raised to 730 ° C, and the industrial pure Al, pure Zn ingot, Mg-Nd and Al-Mn master alloy are added to the melt every 5 minutes, and the melt is stirred within 1 hour Multiple times to make the melt composition uniform;

[0067] S22: After the melt composition is uniform, add ...

Embodiment 2

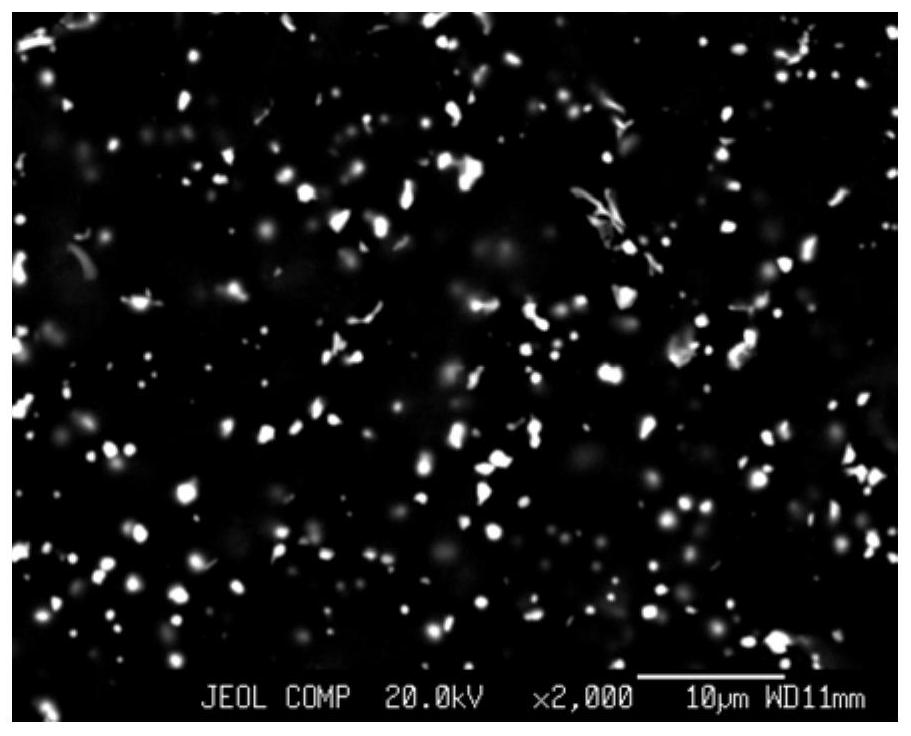

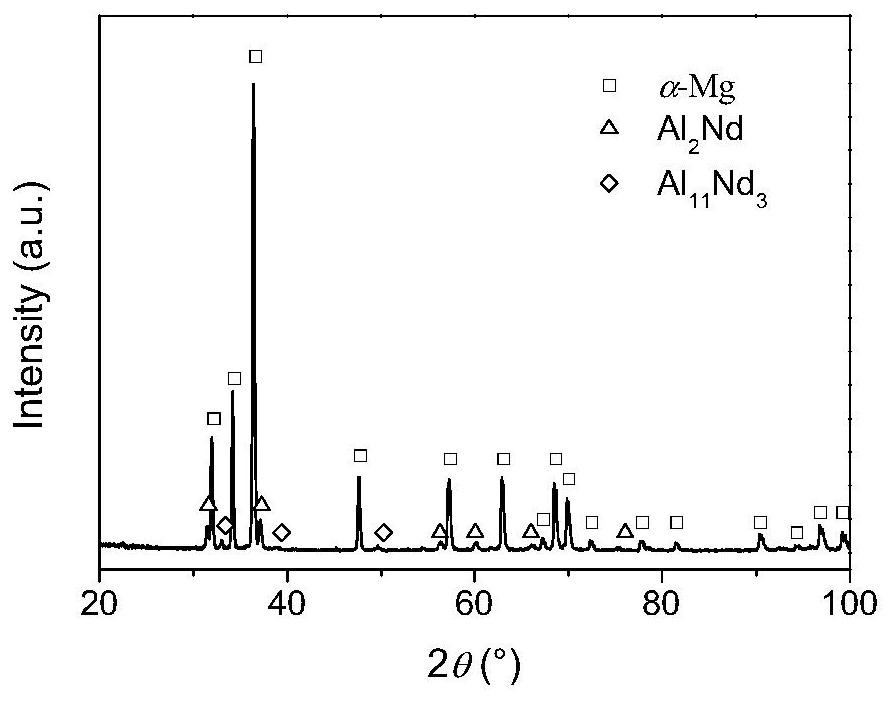

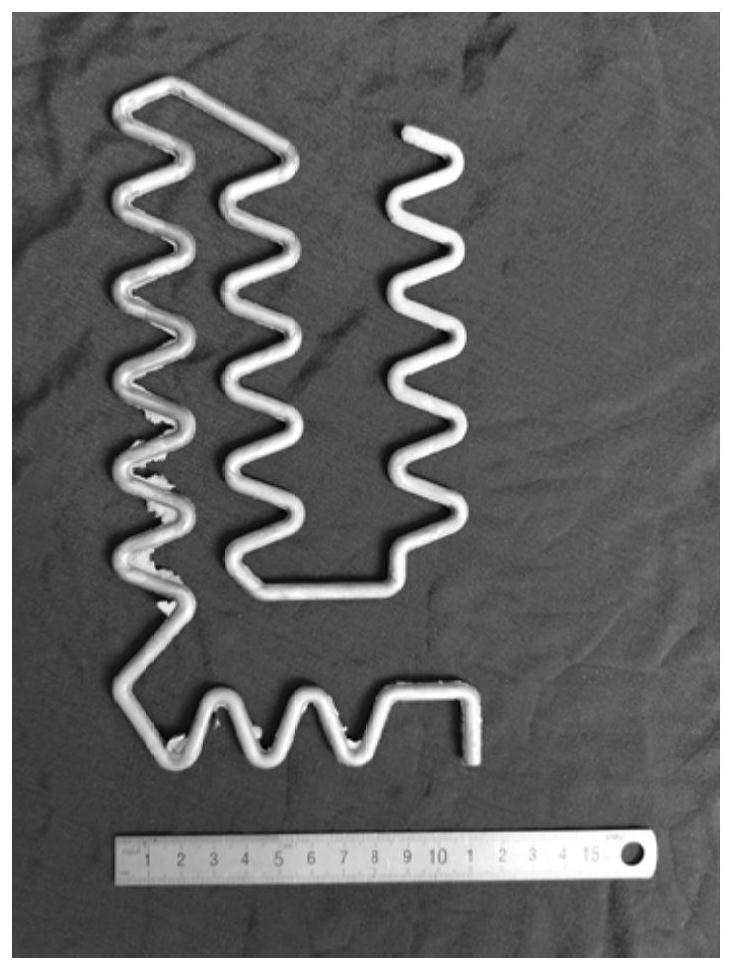

[0072] see figure 1 , figure 2 as well as image 3 , the present embodiment provides a die-casting magnesium alloy, the weight percent of the alloy composition is: Al: 3.1%, Nd: 3.1%, Zn: 0.6%, Mn: 0.1%, and the balance is Mg, which is prepared by the following method get:

[0073] S1: Weigh industrially pure Mg, pure Al, pure Zn ingots and Mg-Nd, Al-Mn master alloy ingots according to the corresponding weight percentage and the corresponding yield of each element;

[0074] S2: Melting, refining, cooling, deslagging and die-casting are carried out in sequence for each raw material.

[0075] Wherein, step S2 specifically includes:

[0076] S21: in CO 2 and SF 6 Under the protection of mixed gas, after the industrial pure Mg is melted, the temperature is raised to 730 ° C, and the industrial pure Al, pure Zn ingot, Mg-Nd and Al-Mn master alloy are added to the melt every 5 minutes, and the melt is stirred within 1 hour Multiple times to make the melt composition uniform;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Flow length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com