Bicomponent fiber with piezoelectric effect, fabric with piezoelectric effect, preparing method of bicomponent fiber with piezoelectric effect and preparing method of fabric with piezoelectric effect

A bi-component fiber and piezoelectric effect technology, applied in fabrics, fiber processing, textiles, etc., can solve the problems of excessive area, limited number of bending times of films, susceptibility to friction, bending and loss, etc., to achieve wide application, Effect of good electrical conductivity and piezoelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

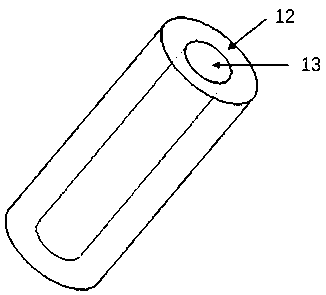

[0022] Such as figure 1 The shown bicomponent fiber with piezoelectric effect includes a conductive high-density polyethylene core layer 13 and a polyvinylidene fluoride sheath layer 12 with piezoelectric effect, and the inner layer of the high-density polyethylene core layer 13 is Contains 5-15% carbon black.

[0023] In this embodiment, in order to ensure that the high-density polyethylene core layer 13 has the best conductive effect, the high-density polyethylene core layer 13 preferably contains 10% carbon black to ensure the best conductive effect.

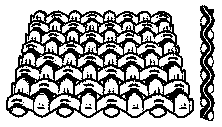

[0024] The fiber core of the piezoelectric bicomponent fiber is welded between two layers of low-density polyethylene containing 5-15% carbon black to connect all fiber ends. The system is compressed in a high-temperature press at 135°C. become.

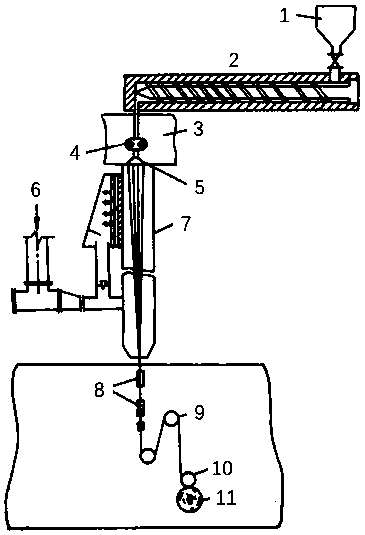

[0025] The above-mentioned method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com