Construction method for repairing ground deformation joint

A construction method and technology of deformation joints, applied to pavement details, roads, roads, etc., can solve the problems of insufficient floating resistance, damage, corrosion of water-stop steel plates and rubber water-stop belts, etc., and achieve good water-stop and drainage effects and prolong Structural life, the effect of reducing corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

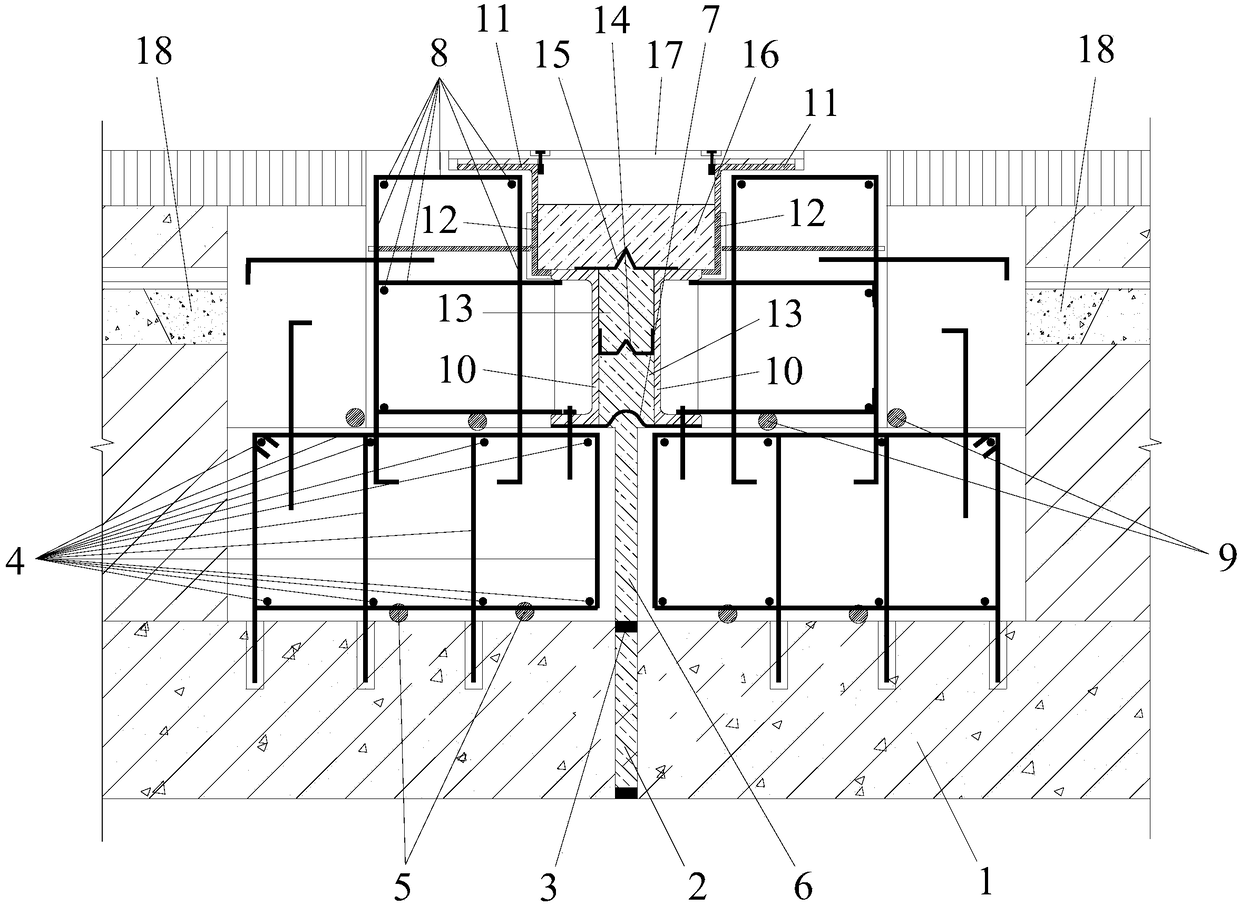

[0032] Such as figure 1 As shown, a construction method for repairing ground deformation joints of the present invention comprises the following steps:

[0033] A. In order to prevent the danger of water gushing and sand gushing after the surface layer concrete is broken, solidify the grouting on the back of the two side walls of the deformation joint and the sediment under the bottom plate 1. After the grouting strength meets the design requirements, the follow-up process construction will be carried out. Blind spot grouting and there is a layer of sand and rocks between the surface layer and the floor concrete, so the grouting plugging cannot stop the open water, but can only initially solidify the sediment;

[0034] B. The surface layer concrete at the 2 original damaged deformation joints is removed. After the removal, both sides of the drainage ditches on both sides of the road are blocked, and then water retaining walls are built at both ends of the removed surface to cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com