Drying device

The technology of drying device and drying cylinder is applied in the directions of drying, drying machine, drying gas arrangement, etc., which can solve the problems of different size and moisture of straw, not meeting people's requirements for use, and not enough to meet the requirements of use, etc. Improve drying effect, simple structure and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

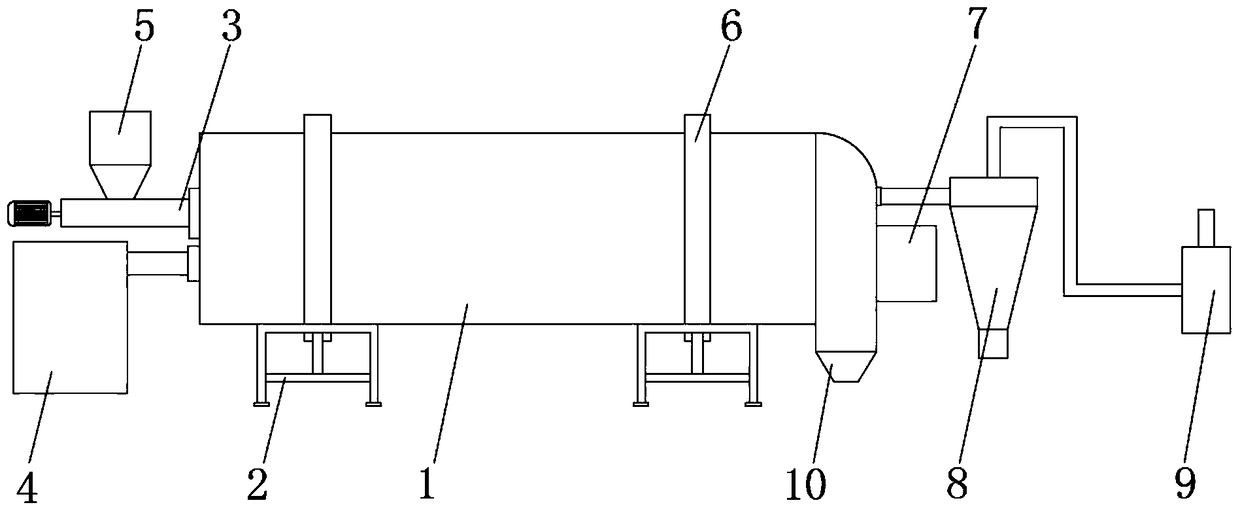

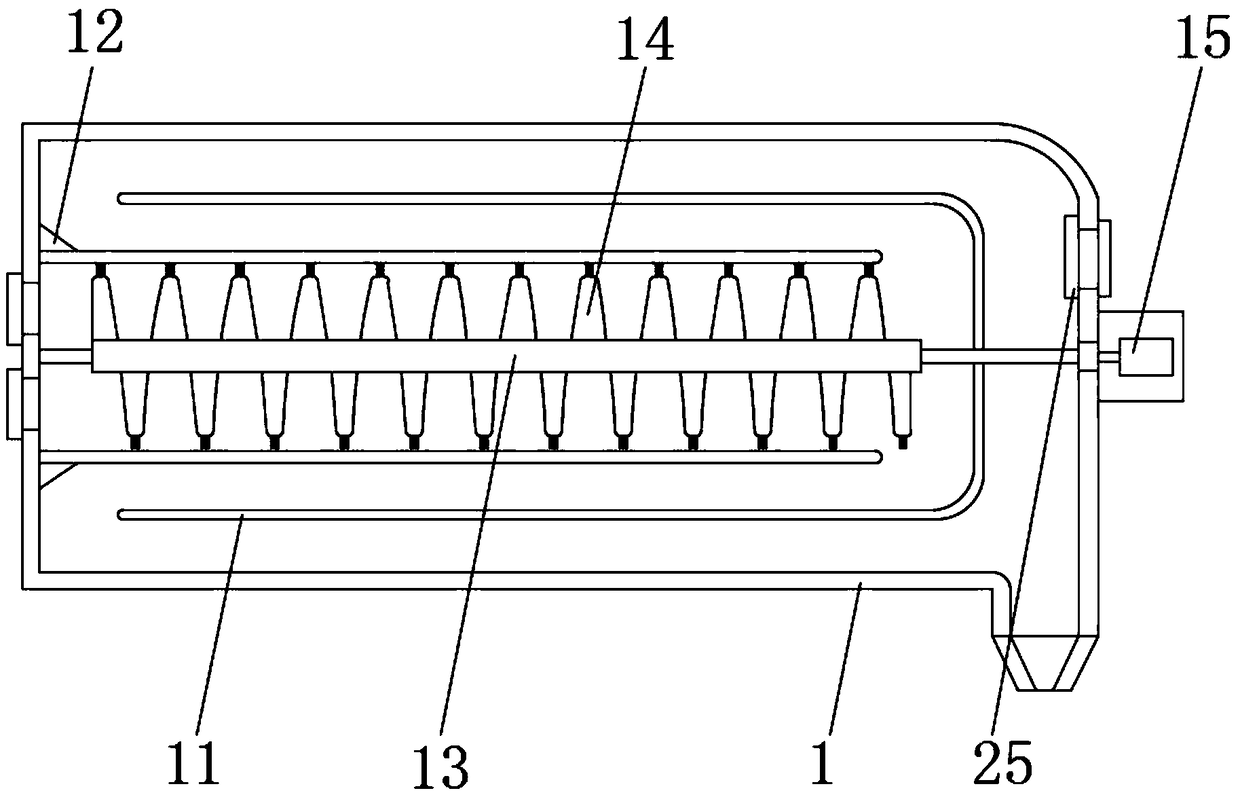

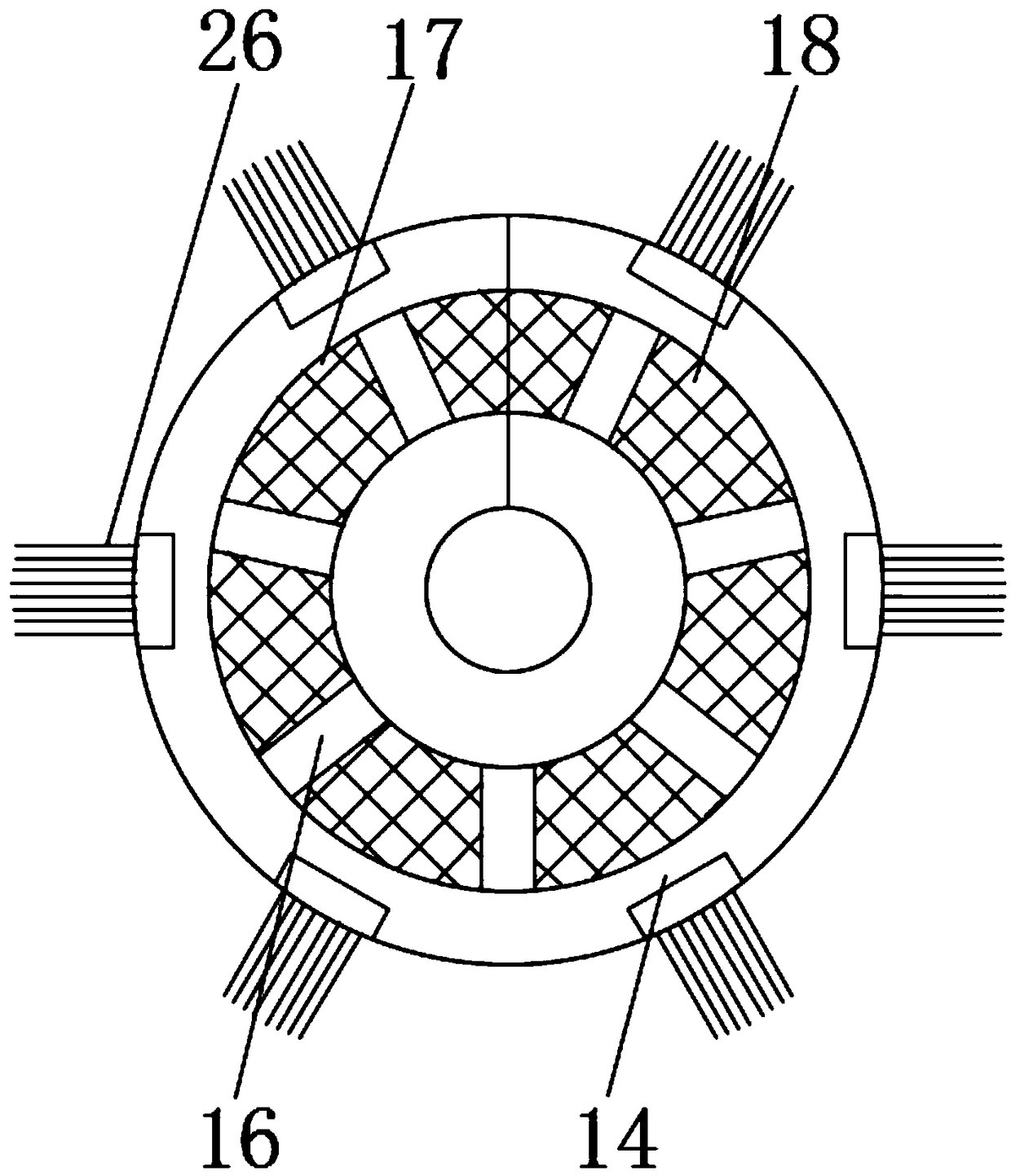

[0029] Such as Figure 1-5 As shown, a drying device includes a drying cylinder 1, a support frame 2 is fixedly installed on the outer surface of the lower end of the drying cylinder 1, a screw feeder 3 and a hot blast stove 4 are arranged on one side of the drying cylinder 1, and The spiral feeder 3 is located above the hot blast stove 4, the outer surface of the spiral feeder 3 is provided with a feeding barrel 5 near one end, the outer surface of the drying barrel 1 is fixedly equipped with a fixing ring 6, and the drying barrel 1 is far away from the An electrical box 7 is fixedly installed in the middle of the outer surface of one end of the hot blast stove 4, and the side of the electrical box 7 away from the drying cylinder 1 is provided with a cyclone dust collector 8 and an induced draft fan 9, and the cyclone dust collector 8 is located on the side of the induced draft fan 9 One side of the electrical box 7 is located at the lower outer surface of the drying cylinder...

Embodiment 2

[0033] Such as Figure 1-5 As shown, a drying device includes a drying cylinder 1, a support frame 2 is fixedly installed on the outer surface of the lower end of the drying cylinder 1, a screw feeder 3 and a hot blast stove 4 are arranged on one side of the drying cylinder 1, and The spiral feeder 3 is located above the hot blast stove 4, the outer surface of the spiral feeder 3 is provided with a feeding barrel 5 near one end, the outer surface of the drying barrel 1 is fixedly equipped with a fixing ring 6, and the drying barrel 1 is far away from the An electrical box 7 is fixedly installed in the middle of the outer surface of one end of the hot blast stove 4, and the side of the electrical box 7 away from the drying cylinder 1 is provided with a cyclone dust collector 8 and an induced draft fan 9, and the cyclone dust collector 8 is located on the side of the induced draft fan 9 One side of the electrical box 7 is located on the outer surface of the lower end of the dryi...

Embodiment 3

[0038] Such as Figure 1-5As shown, a drying device includes a drying cylinder 1, a support frame 2 is fixedly installed on the outer surface of the lower end of the drying cylinder 1, a screw feeder 3 and a hot blast stove 4 are arranged on one side of the drying cylinder 1, and The spiral feeder 3 is located above the hot blast stove 4, the outer surface of the spiral feeder 3 is provided with a feeding barrel 5 near one end, the outer surface of the drying barrel 1 is fixedly equipped with a fixing ring 6, and the drying barrel 1 is far away from the An electrical box 7 is fixedly installed in the middle of the outer surface of one end of the hot blast stove 4, and the side of the electrical box 7 away from the drying cylinder 1 is provided with a cyclone dust collector 8 and an induced draft fan 9, and the cyclone dust collector 8 is located on the side of the induced draft fan 9 One side of the electrical box 7 is located on the outer surface of the lower end of the dryin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap