Method for rapidly estimating film thickness uniformity of hemispherical harmonic oscillator based on optical simulation

A hemispherical oscillator and optical simulation technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of complex process, affecting oscillator performance, long experimental period, etc., achieving high timeliness, improved efficiency, and easy readability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

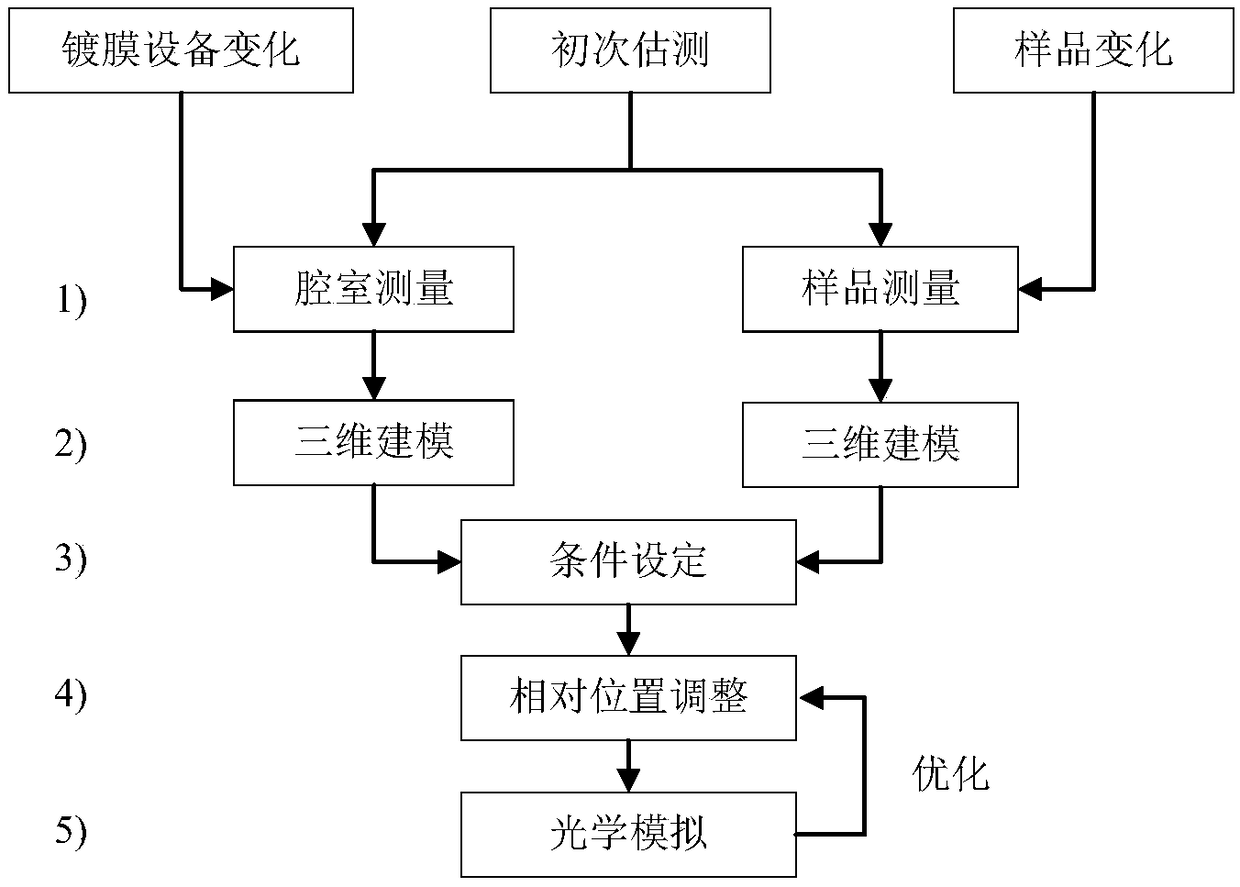

[0029] Such as figure 1 As shown, this embodiment includes the following steps:

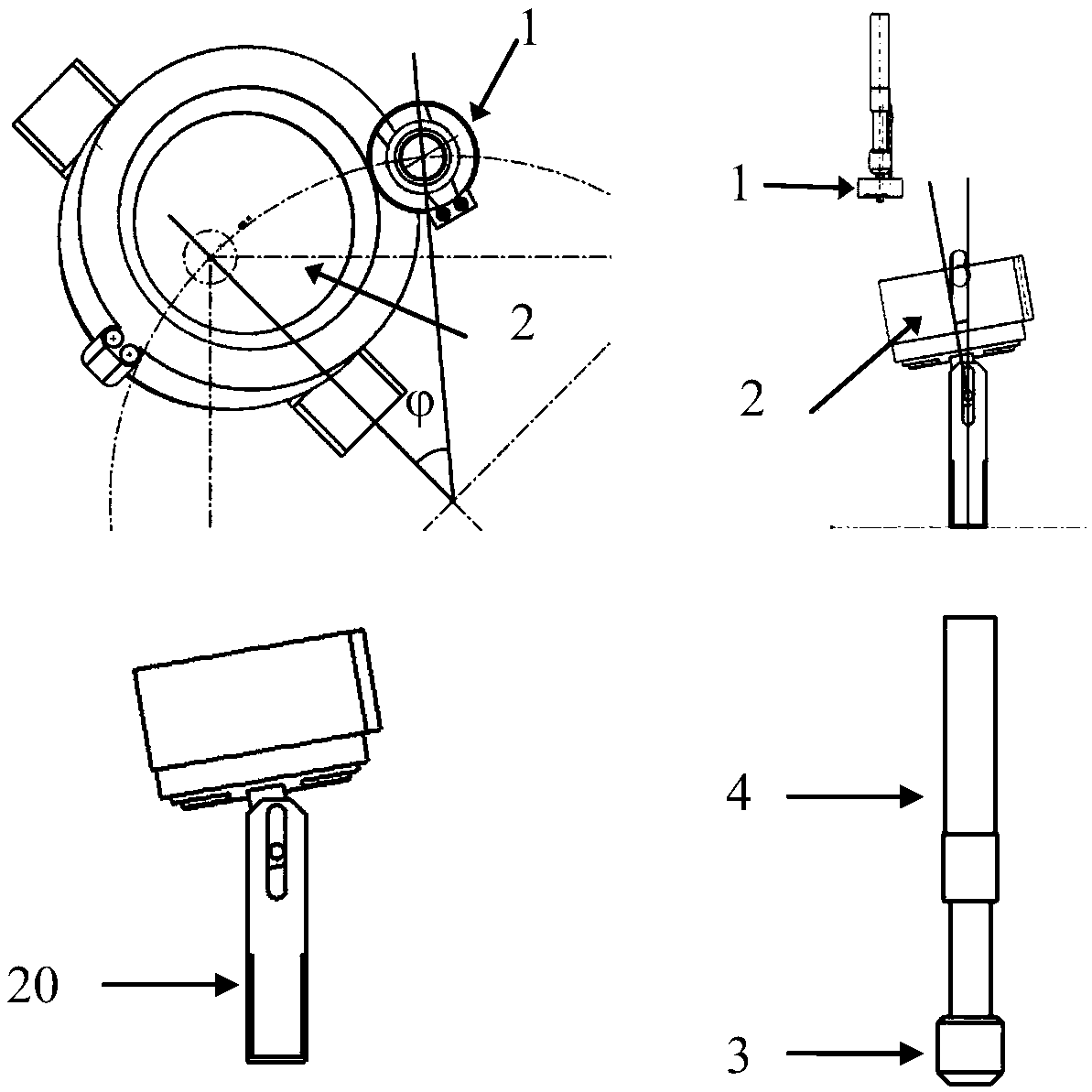

[0030] 1) Measurement: measurement in the vacuum chamber of the coating equipment, including but not limited to the measurement of the shape and structure of the target 2 in the coating equipment, the measurement of the target position, the measurement of the relative position between the coating station and the target; the sample that needs to be coated is hemispherical resonance Measurement of the external dimensions of sub-1;

[0031] 2) Three-dimensional modeling: establish a three-dimensional model of the coating chamber, and establish a real-scale three-dimensional simplified model in the computer according to the measurement results, including but not limited to structures such as the target model 20, chuck model 3, and transmission mechanism model 4; 3D simplified model of the sample to be coated;

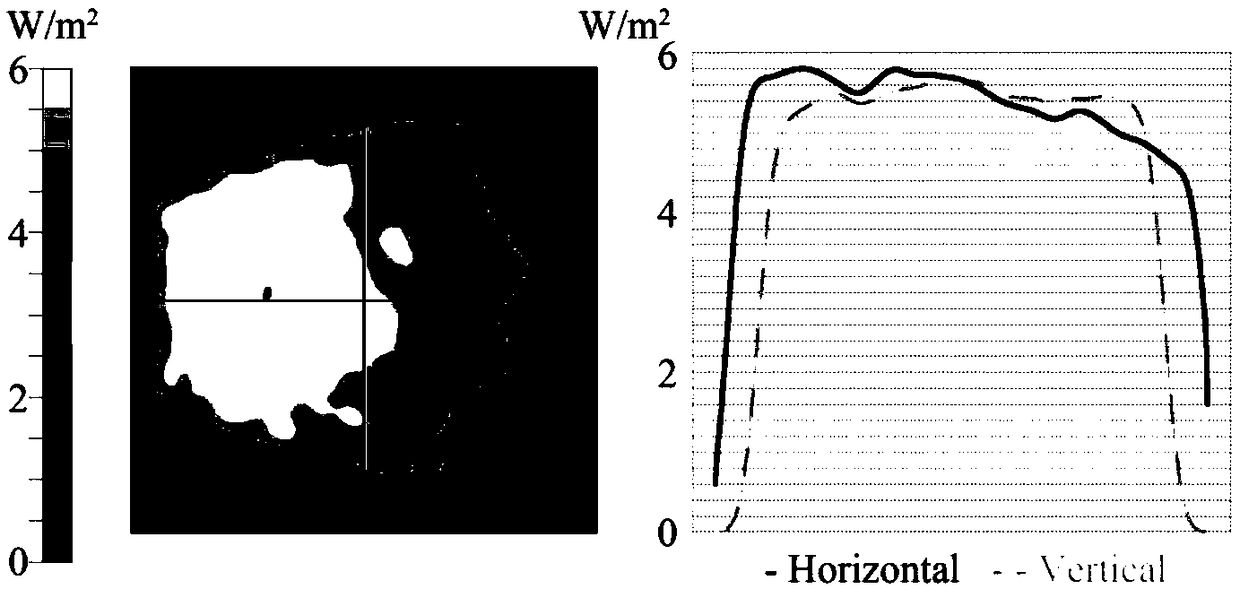

[0032] 3) Definition of simulation conditions: regardless of scattering or diffraction, ...

Embodiment 2

[0036] In this embodiment, on the basis of Embodiment 1, when the first simulation is completed, the adjustment can be directly started from step 4) when the coating equipment and coating samples have not changed, that is, after step 5) is completed, return to Step 4), and repeating steps 4) and 5) multiple times to obtain the parameter combination that makes the uniformity of the film thickness optimal. At the same time, the simulation data fed back each time is used to summarize the rules, optimize the parameters, and finally obtain the parameter values that make the film thickness uniformity meet the requirements. The parameters optimized by simulation can be used to adjust the relative position of the target and the sample in the actual coating work. Compared with Embodiment 1, this embodiment can estimate the film thickness uniformity more accurately; the parameters optimized through simulation can be used to adjust the relative positions of the target and the sample in...

Embodiment 3

[0038] On the basis of the previous two embodiments, when the coating equipment changes or the sample changes, the present invention only needs to re-measure the changed part and perform three-dimensional modeling, that is, when the parameter data measured by the chamber changes, then Update the three-dimensional model of the coating chamber; when the parameter data of the sample measurement changes, update the three-dimensional model of the coating sample; on the basis of the updated three-dimensional model, then perform condition setting, relative position adjustment and optical simulation step by step Estimated film thickness uniformity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com