On-line calibration method of thermal imager in space simulation environment

A technology for simulating the environment and thermal imagers, which is applied to instruments, scientific instruments, radiation pyrometry, etc. It can solve the problems of low temperature of the standard plate, great influence, and large measurement errors, etc., and achieves strong environmental adaptability and measurement Small error and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The characteristics and exemplary embodiments of various aspects of the present invention will be described in detail below. In order to make the purpose, technical solutions and advantages of the present invention more clear, the detailed description will be described below in conjunction with the accompanying drawings and embodiments. It should be understood that the described specific embodiments are only regarded as explaining the present invention, not as limiting the present invention. It will be apparent to one skilled in the art that the present invention may be practiced without some of these specific details.

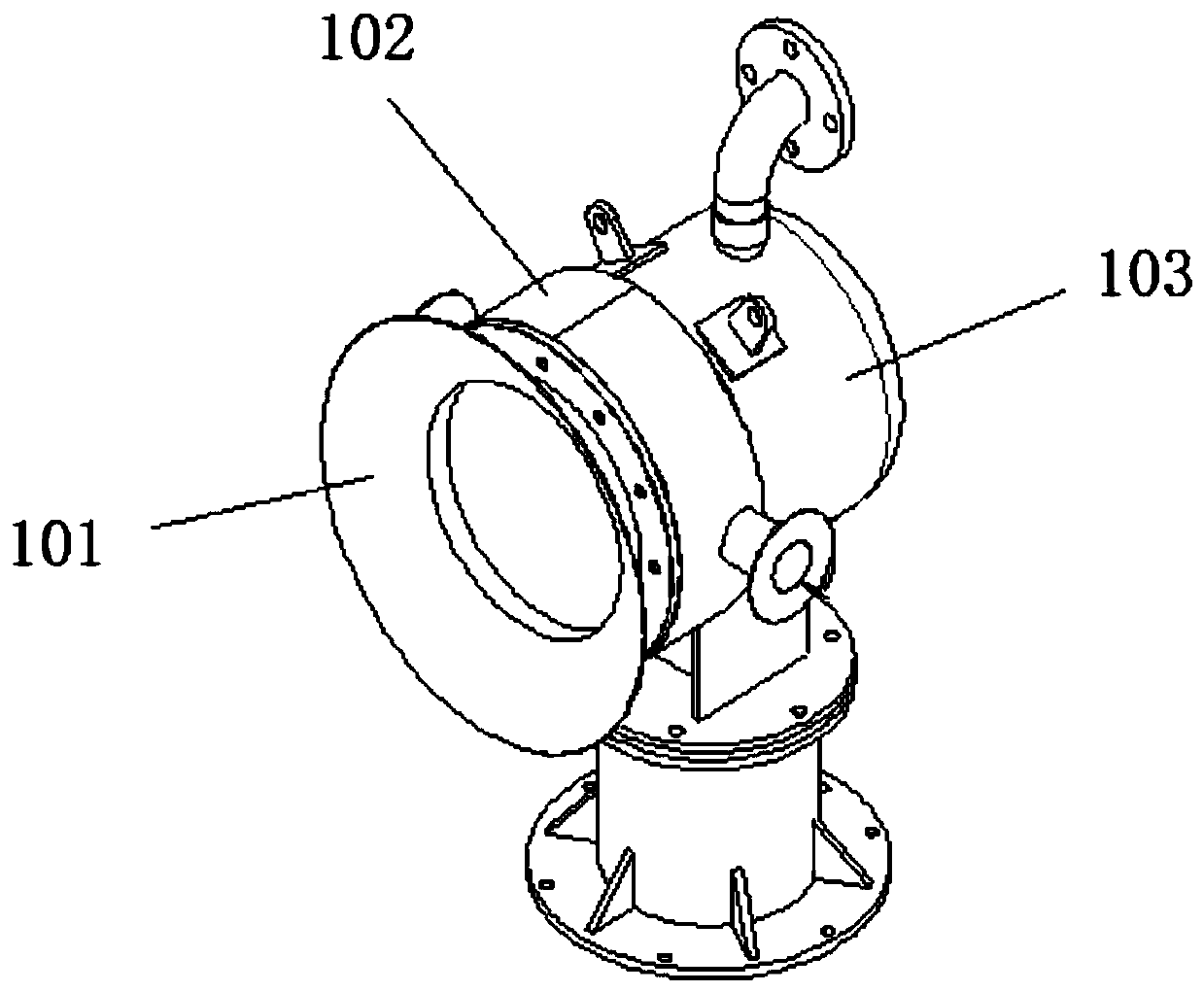

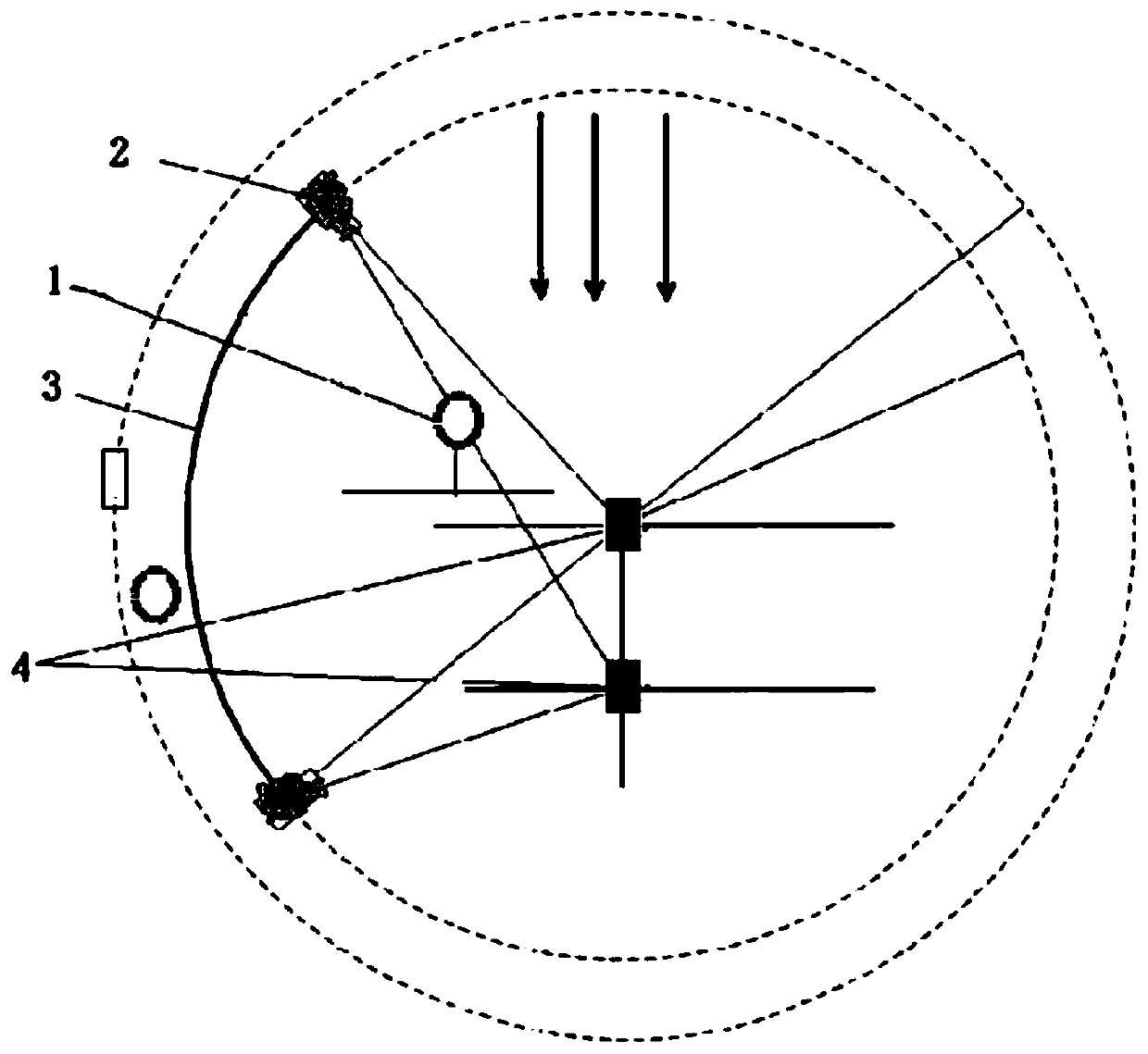

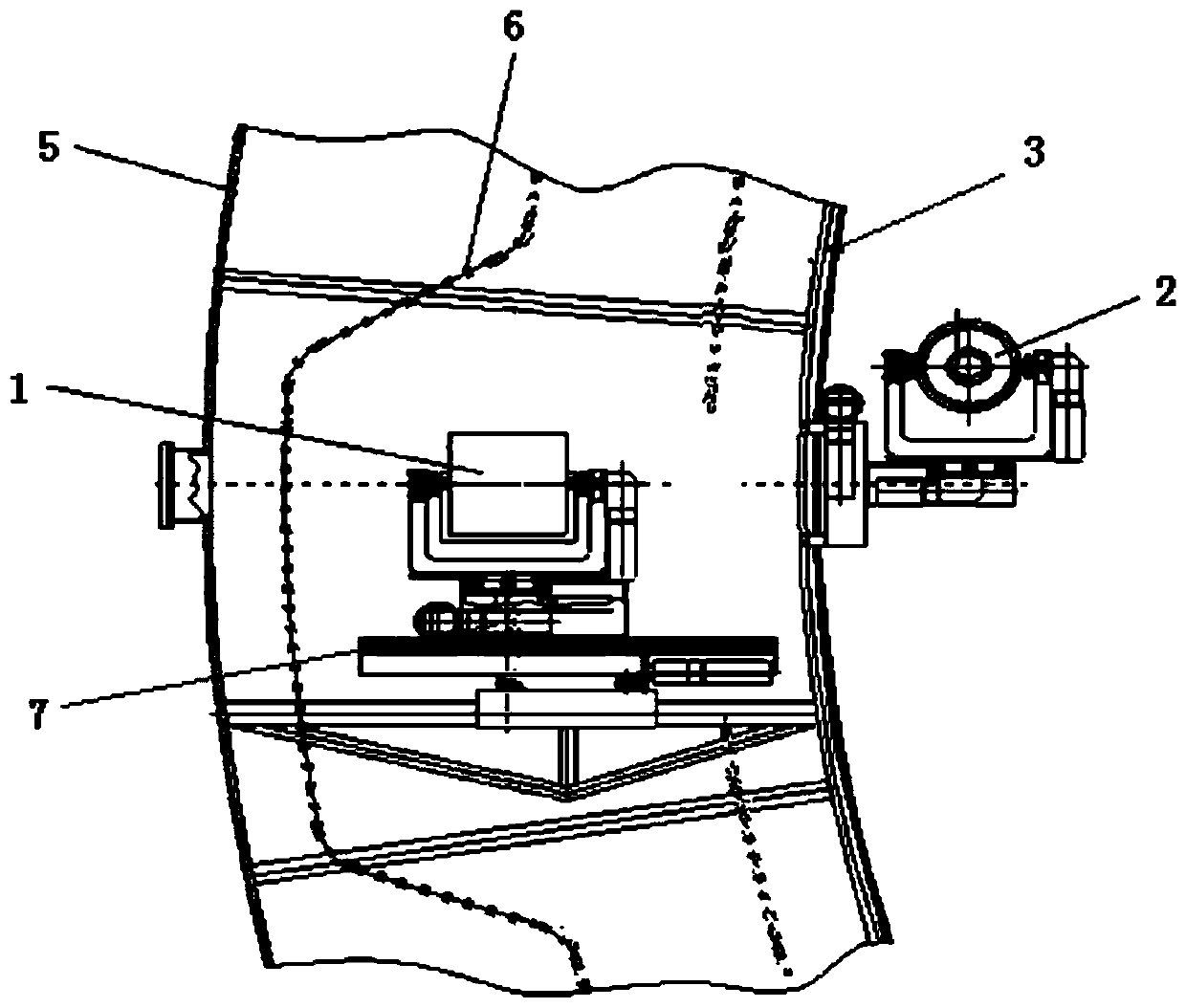

[0036] The invention provides an online calibration method for a thermal imager in a space target infrared radiation simulation test. In the method, a blackbody is used as a calibration device. Such as figure 1 As shown, the main structure of the blackbody is a variable temperature source, which is composed of a radiator 101, a temperature regulating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com