Method and device for detecting high-grade mountain sand concrete for inner steel pipe column

A detection method and detection device technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problem of difficult positioning of defect areas, reduce the proportion of destructive tests, and concrete Pouring quality is difficult to detect and other problems, to achieve the effect of low construction cost, reduced structural damage, and wide promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

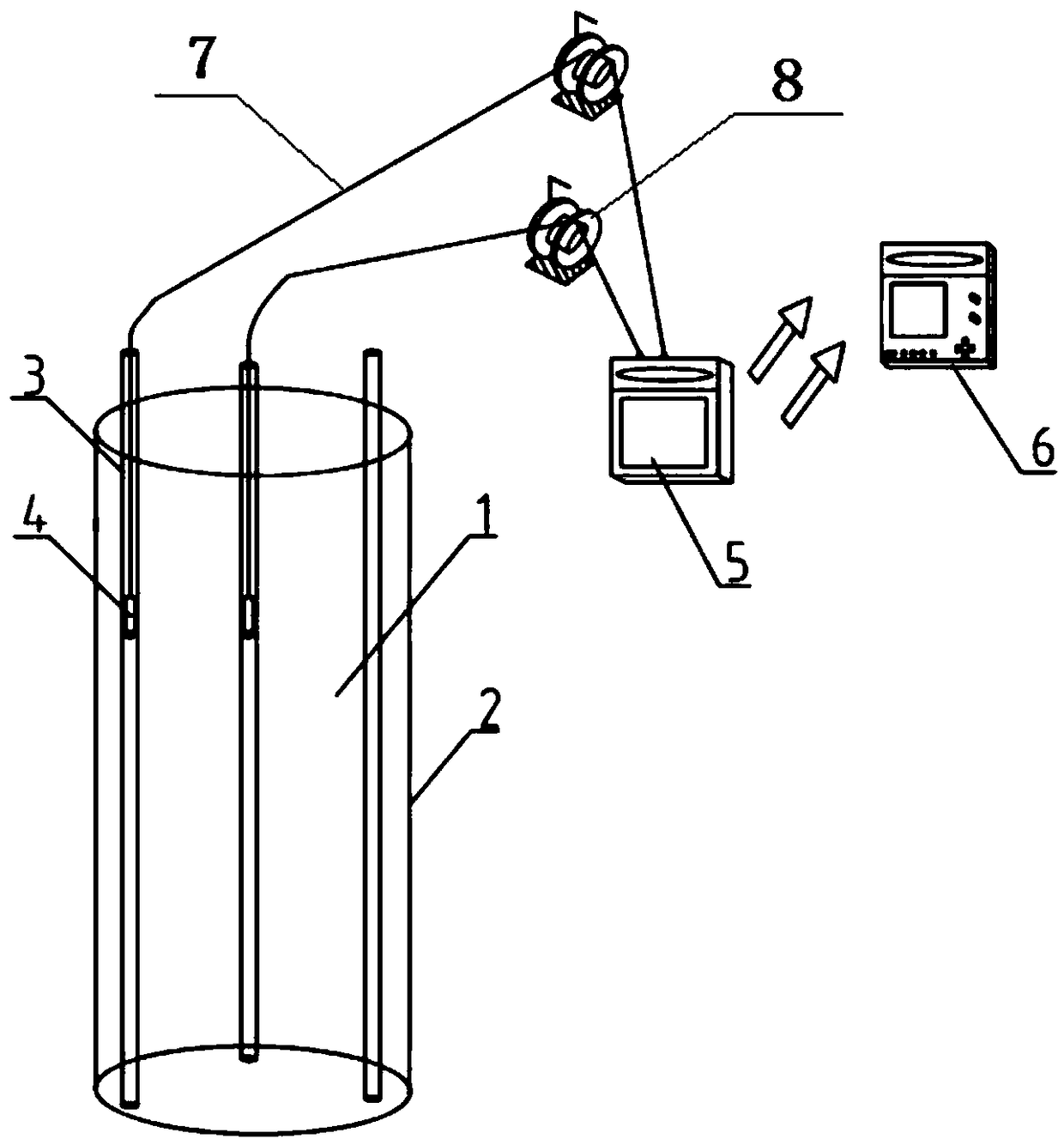

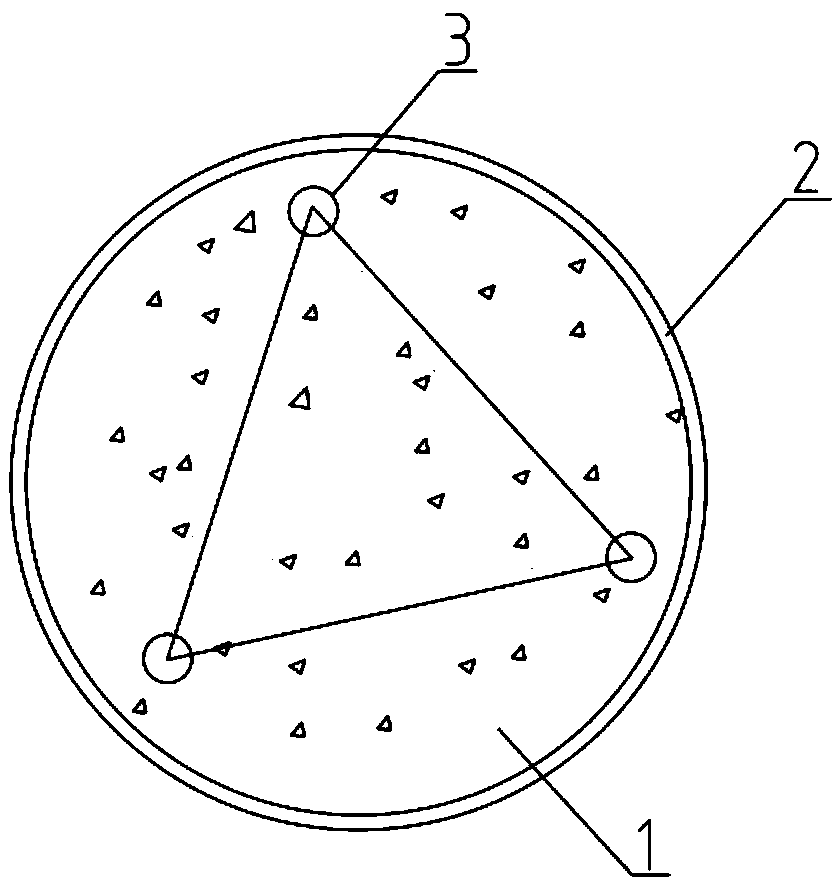

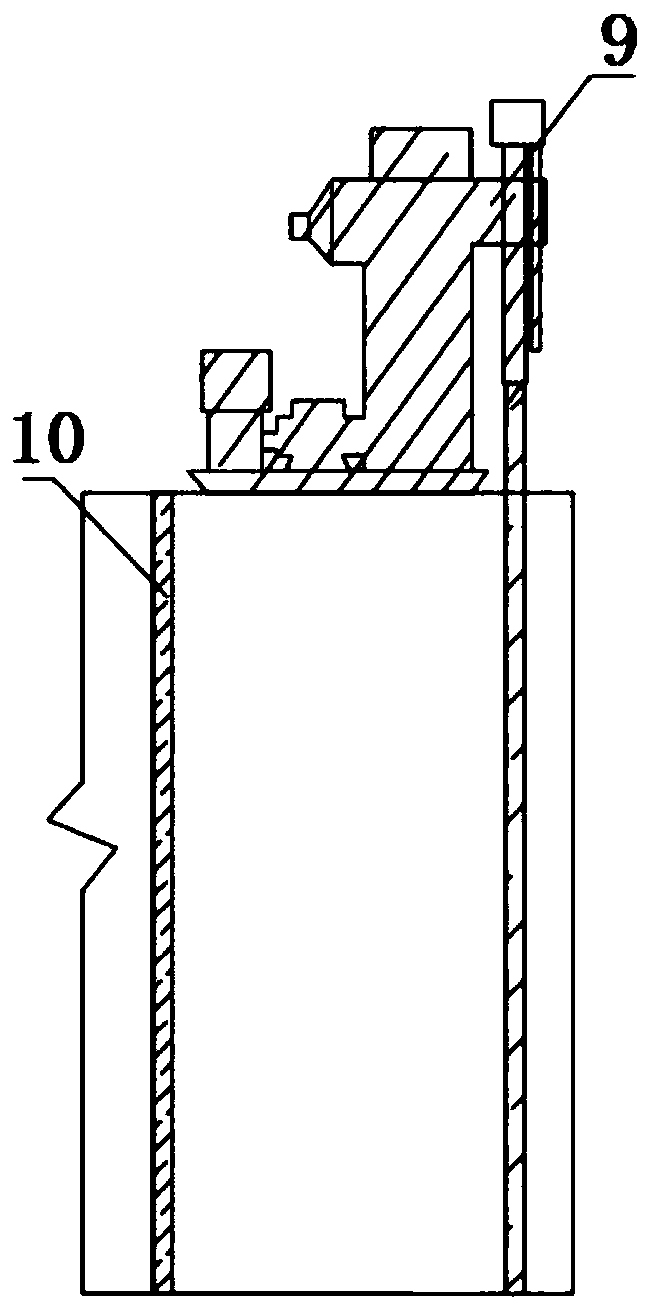

[0034] Embodiment of the present invention: the structural diagram of the detection device for the high-grade mountain sand concrete of the inner column of the steel pipe is as follows figure 1 and figure 2 As shown, it includes three acoustic tubes 3 vertically arranged in the steel pipe column 2, and the three acoustic tubes 3 are respectively located at the three angles of an equilateral triangle. Higher than the steel pipe column 2, a transducer 4 is arranged in two of the acoustic tubes 3, and the transducer 4 is slidingly connected to the inner wall of the acoustic tube 3, and the two transducers 4 are respectively passed through two data lines 7 is connected to the two input ports of the foundation pile cross-hole ultrasonic automatic sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com