A conduction test device

A conduction test and conduction technology, applied in the direction of electrical connection test, etc., can solve the problems of taking up a lot of manpower and operating time, increasing error factors, and low detection efficiency, so as to improve test efficiency and accuracy, improve efficiency and correctness , The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

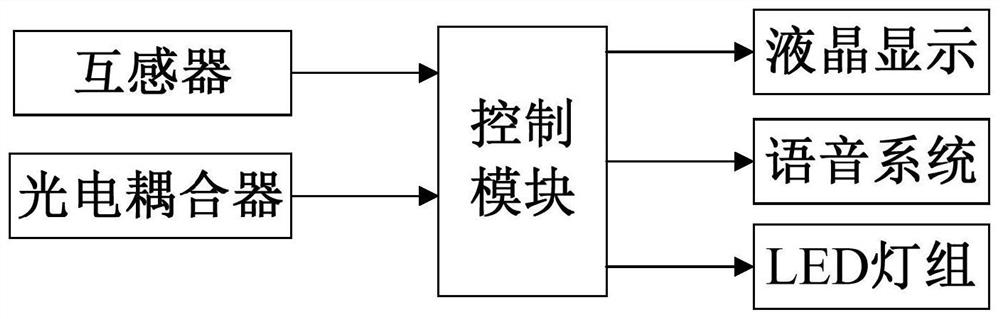

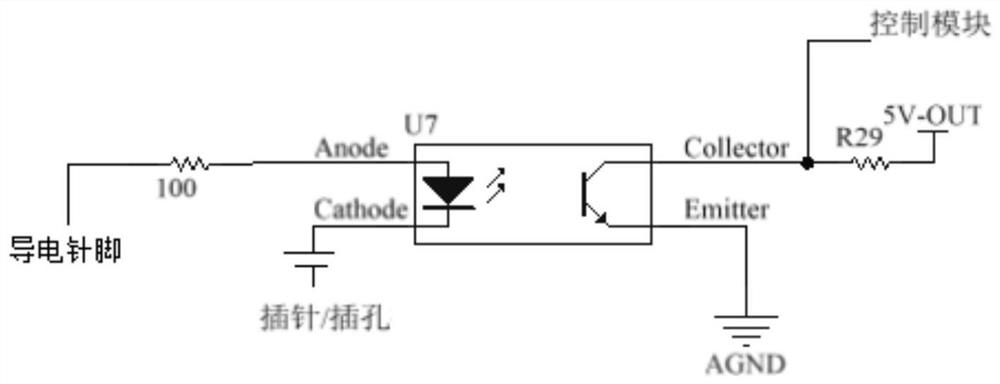

[0034] In this embodiment, the number of photocouplers is the same as the number of connector contact components, refer to image 3 As shown, a test loop is formed between the input terminal of an optocoupler, a voltage source, and a connector contact component, and a pin / hole at both ends of the tested connector. If there is conduction between the pins / holes, the test circuit is conducted, and the output terminal of the photocoupler sends a conduction signal to the control module.

[0035] A current transformer (not shown) is provided on the first wire or the second wire, and the signal output end of the current transformer is connected to the control module. Since the number of pins / holes connected to the connector contact assembly is in multiples of the current, the output signal of each current transformer can be used to judge the current flowing on the wire, and then the current value detected by each current transformer can be compared. It is judged whether each connect...

Embodiment 2

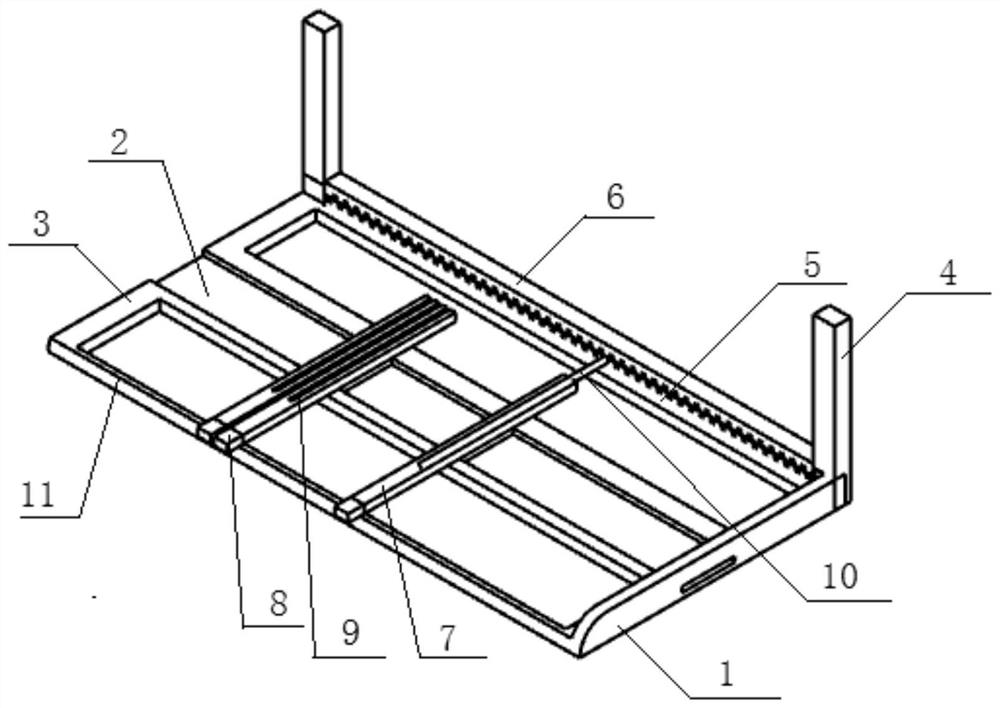

[0045] Based on the conduction test device of embodiment 1, when the connector to be tested is tested, the distance between the connector contact components can be adjusted according to the model specifications or the actual distance between the pins / holes of the connector to be tested, and then by The positioning fixture fixes the conductive pins in the holding holes, thereby fixing the position of the contact components of each connector, and the conductive pins are reliably connected to the conductive ends of the connector contact components, and at the same time, the pins / holes at one end of the connector to be tested are respectively docked A connector contacts the conductive end of the assembly.

[0046] The input end of each photocoupler is used to connect a pin / hole at one end of the electrical connector under test and a conductive pin of a connector contact assembly, so that when the corresponding pin / hole of the connector under test is turned on, a The loop is turned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com