Backlight driving method and device and liquid crystal display device

A technology of backlight drive and optical drive module, which is applied in the field of backlight drive methods, liquid crystal display devices, and devices, can solve problems such as increasing the complexity of backlight drive design, wasting manpower, and material resources, and achieves improved portability, simple method, Avoid the effects of heavy calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

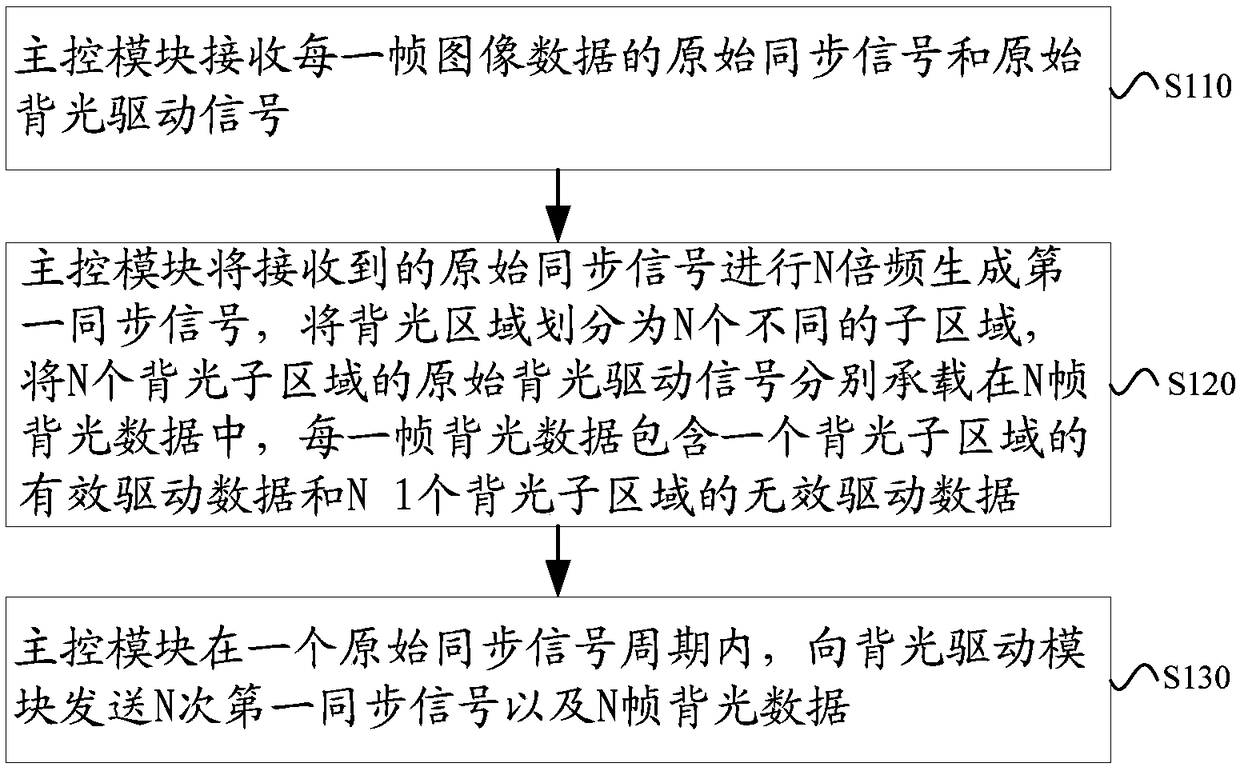

[0020] Such as figure 1 As shown, the embodiment of the present invention provides a backlight driving method, including:

[0021] Step S110: the main control module receives the original synchronization signal and the original backlight driving signal of each frame of image data;

[0022] Step S120: The main control module multiplies the received original synchronization signal by N to generate the first synchronization signal, divides the backlight area into N different sub-areas, and carries the original backlight driving signals of the N backlight sub-areas in N In the frame of backlight data, each frame of backlight data includes valid driving data of one backlight sub-region and invalid driving data of N-1 backlight sub-regions;

[0023] Step S130, the main control module sends the first synchronization signal and N frames of backlight data to the backlight driving module N times within one cycle of the original synchronization signal;

[0024] In the above embodiment,...

Embodiment 2

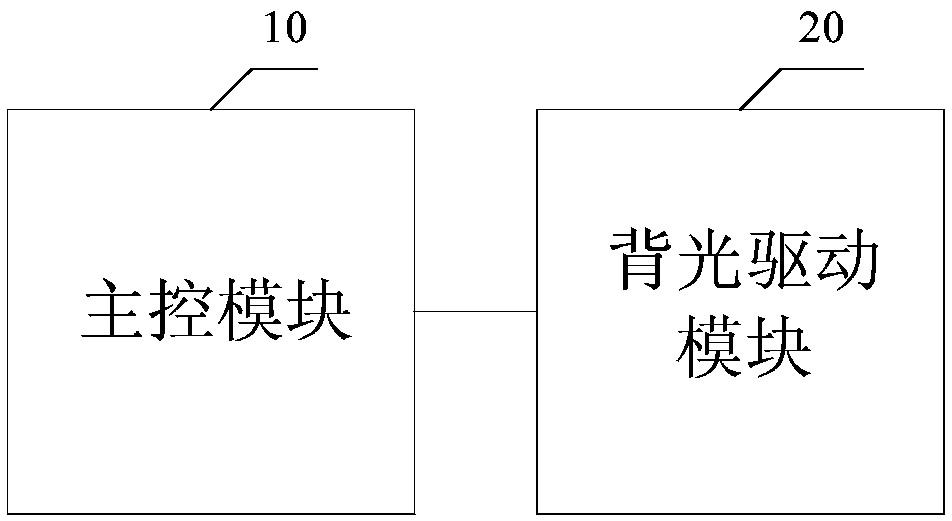

[0029] Such as figure 2 As shown, the embodiment of the present invention provides a backlight driving device, including:

[0030] The main control module 10 is used to receive the original synchronous signal and the original backlight driving signal of each frame of image data; the received original synchronous signal is frequency-multiplied by N to generate the first synchronous signal, and the backlight area is divided into N different sub- region, the original backlight driving signals of N backlight sub-regions are respectively carried in N frames of backlight data, and each frame of backlight data includes valid driving data of one backlight sub-region and invalid driving data of N-1 backlight sub-regions; Send the first synchronization signal N times and N frames of backlight data to the backlight drive module within one original synchronization signal period;

[0031] The backlight driving module 20 is configured to receive a first synchronization signal and backligh...

Embodiment 3

[0036] Such as image 3 As shown, the embodiment of the present invention provides a liquid crystal display device, including the backlight driving device in the above-mentioned embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com