Camera component and assembling method as well as terminal

A camera assembly and assembly method technology, applied in installation, optical components, image communication, etc., can solve the problems affecting the size and volume of the camera module, and achieve the effect of reducing height, realizing electrical connection, and improving electrical connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

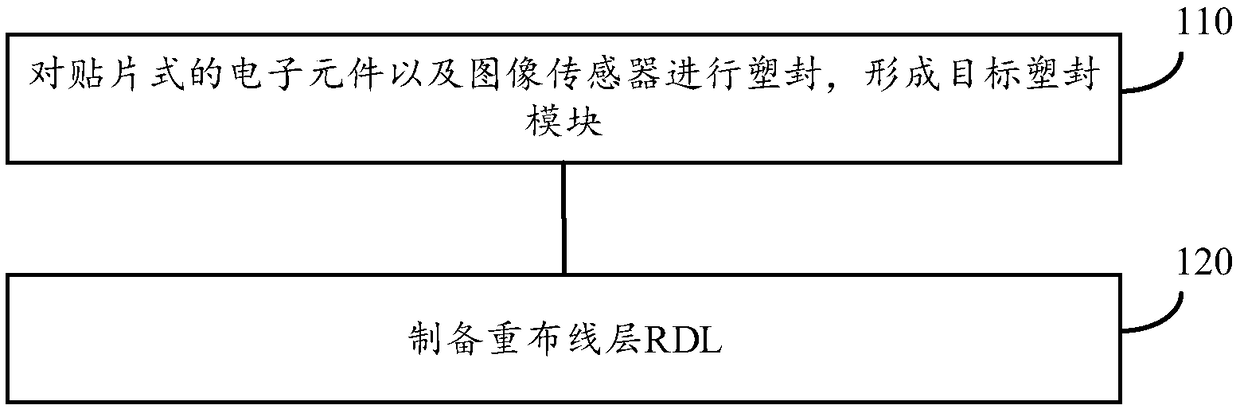

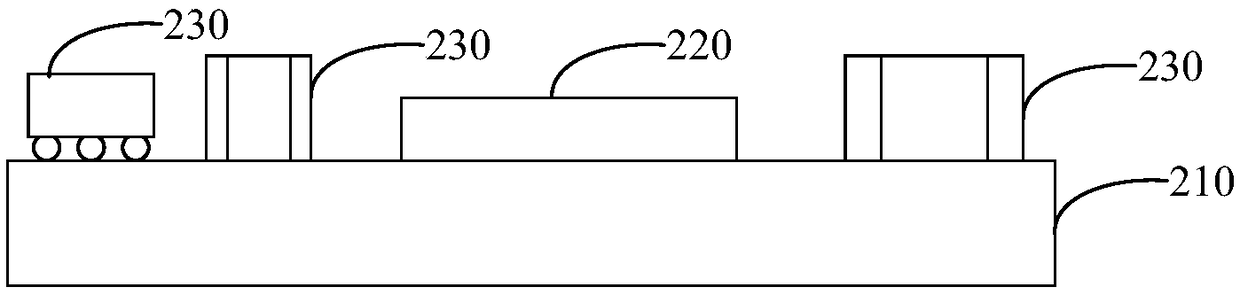

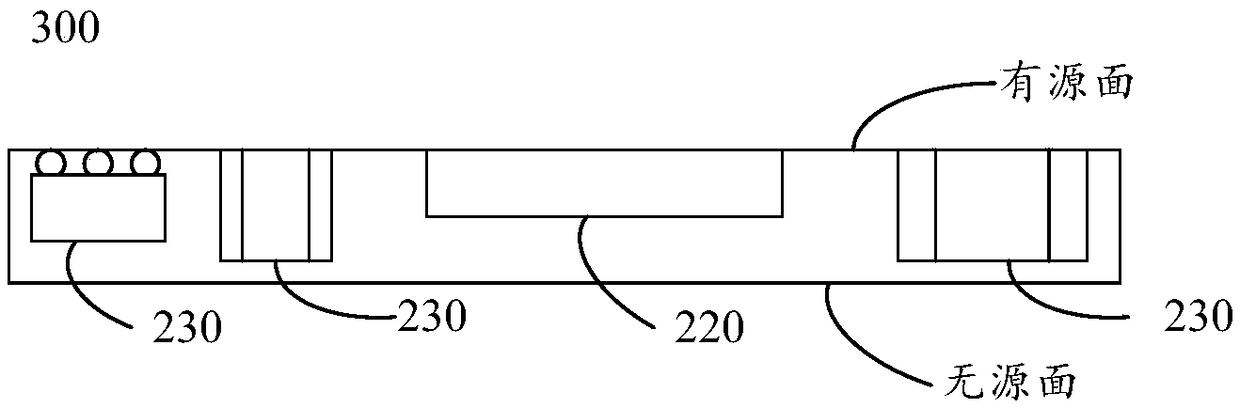

[0044] The technical solution in this application will be described below with reference to the accompanying drawings.

[0045]It should be understood that the type of terminal equipment mentioned in the embodiment of the present application is not specifically limited, and the terminal equipment may include but not limited to mobile station (mobile station, MS), mobile phone (mobile telephone), user equipment (user equipment, UE), mobile phone (handset), portable equipment (portable equipment), cellular phone, cordless phone, session initiation protocol (session initiation protocol, SIP) phone, wireless local loop (wireless local loop, WLL) station, personal digital processing (personal digital assistant, PDA), radio frequency identification (radio frequency identification, RFID) terminal equipment for logistics, handheld devices with wireless communication functions, computing devices or other devices connected to wireless modems, vehicle-mounted devices, wearable devices, In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com