Robot joint variable stiffness module capable of locally linearly adjusting stiffness value

A robot joint and manual adjustment technology, applied in the field of robots, can solve the problems of large volume and small rigidity adjustment range of variable rigidity rotating flexible joints, and achieve the effect of realizing flexible drive output, large rigidity adjustment range and reducing overall size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

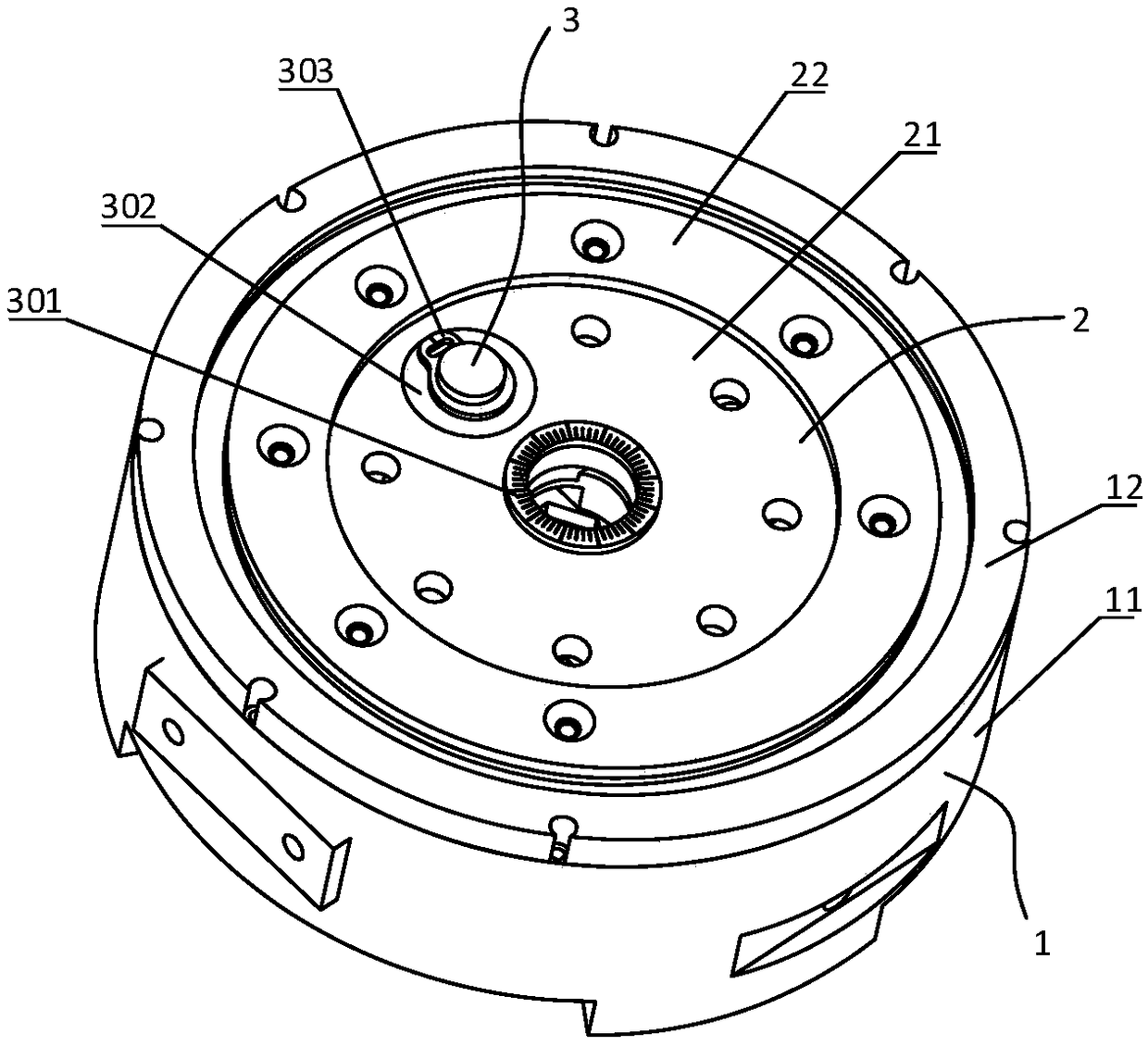

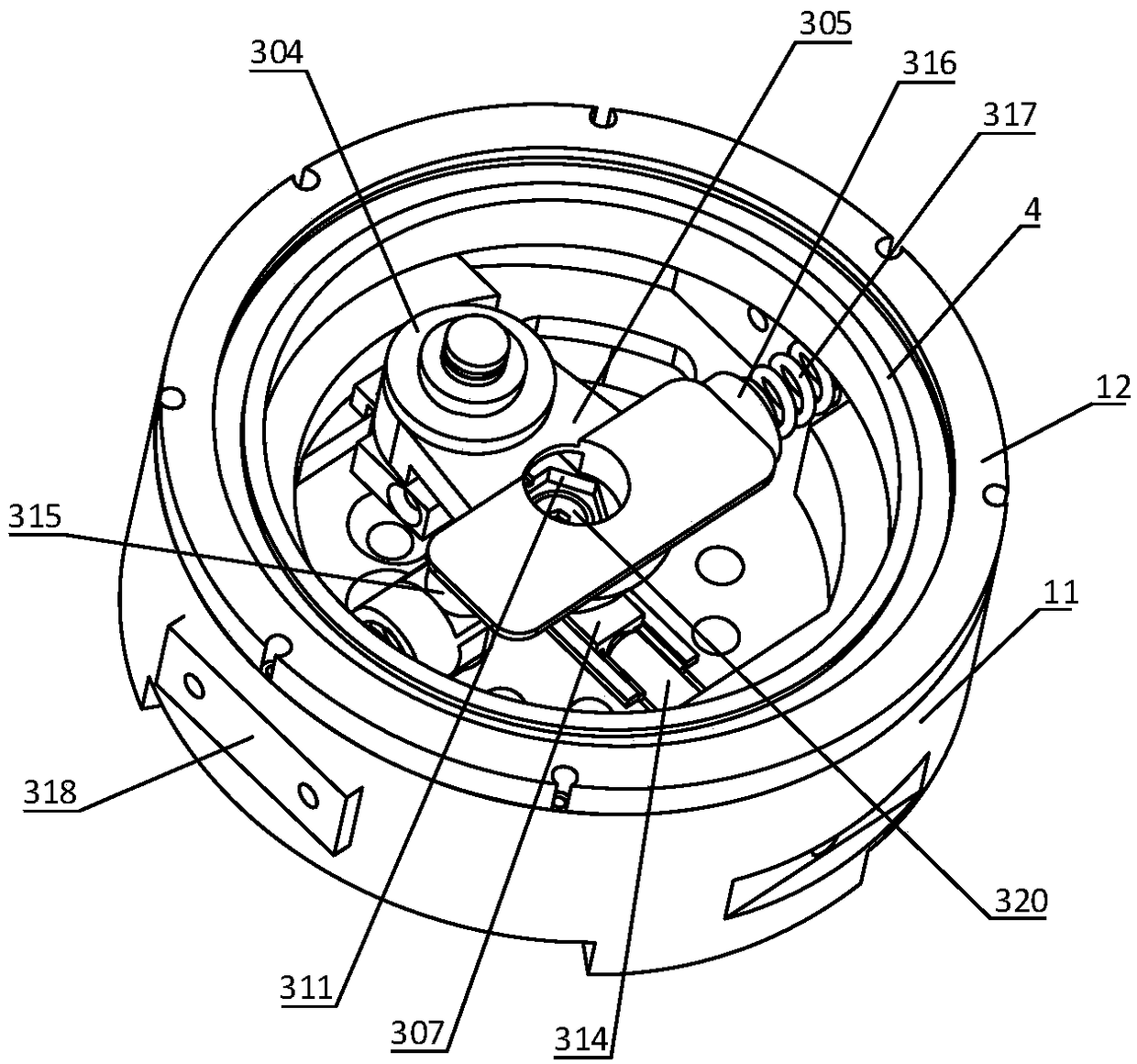

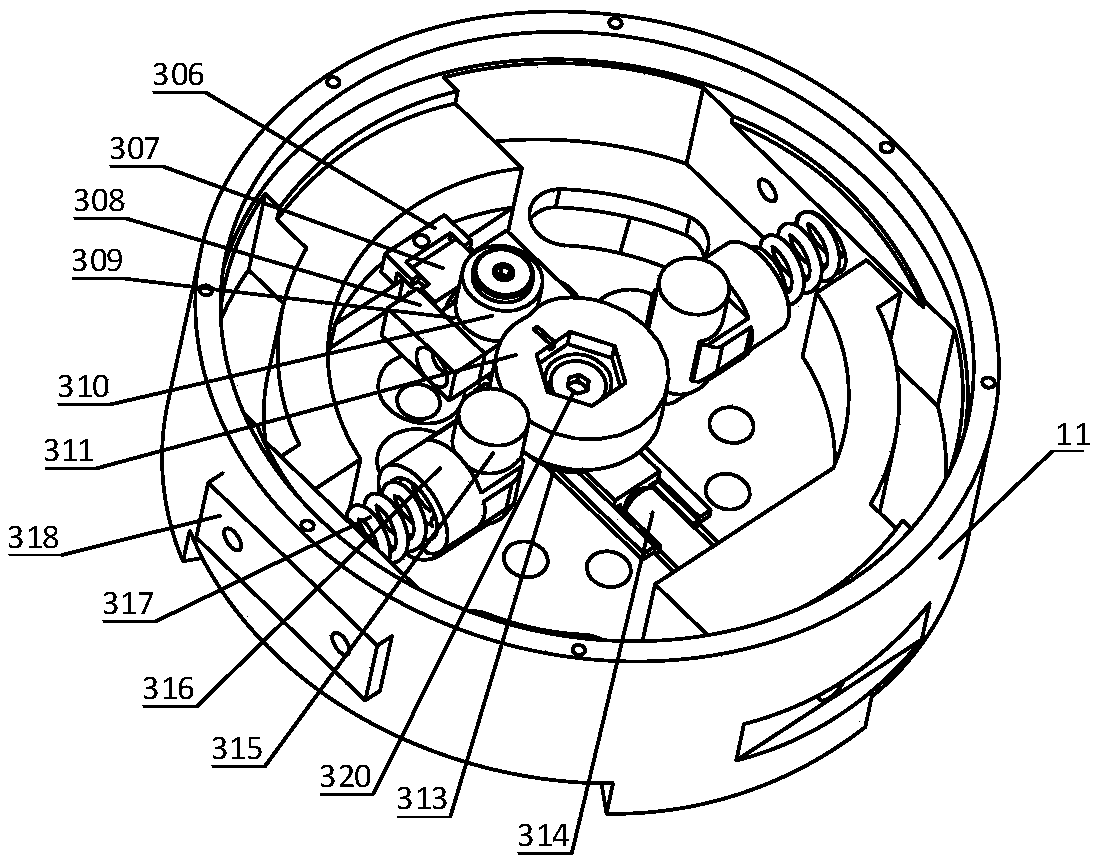

[0034] Such as Figure 1 to Figure 5 As shown, this embodiment discloses a robot joint variable stiffness module that can manually adjust the stiffness locally linearly. The variable stiffness module mainly includes an input part 1 , an output part 2 , and a stiffness adjustment part 3 . A bearing 4 is provided between the input part 1 and the output part 2 to bear the non-torque load of the whole module and make the input part 1 and the output part 2 relatively rotatable.

[0035] Specifically, the input part 1 includes a base 11 and a base bearing retaining ring 12 , the base bearing retaining ring 12 is connected to the base 11 by bolts, and is fixed with the outer ring of the bearing 4 . The base 11 is provided with necessary installation holes and lightening structures. The base 11 is also provided with a guide groove for constraining the large slider 307 and the roller 315 .

[0036] Specifically, the output part 2 includes an output disk 21 and an output disk bearing re...

Embodiment 2

[0044] This embodiment discloses a robot joint variable stiffness module that can manually adjust the stiffness value locally linearly, including an input part 1 , an output part 2 and a stiffness adjustment part 3 . A bearing 4 is provided between the input part 1 and the output part 2 to bear the non-torque load of the whole module and enable the input part 1 and the output part 2 to rotate relatively. The non-torque load is filtered out through the function of the bearing 4, so as to ensure that only the torque load is loaded into the variable stiffness module. Stiffness adjustment part 3 comprises stage clip 317, cam type lever 305, stiffness adjustment fulcrum 310 and fulcrum adjustment part; One end keeps in contact with the compression spring 317 all the time. When the external load is loaded on the output disk 21 of the variable stiffness module, it will act on the compression spring 317 after passing through the cam lever 305. At this time, the compression spring 317...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com