Mold closing mechanism of injection molding machine

A mold clamping mechanism and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of high processing cost, insufficient compactness, and high oil cylinder cost, and achieve the effects of stable and accurate motion, oil cylinder cost saving, and compact mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

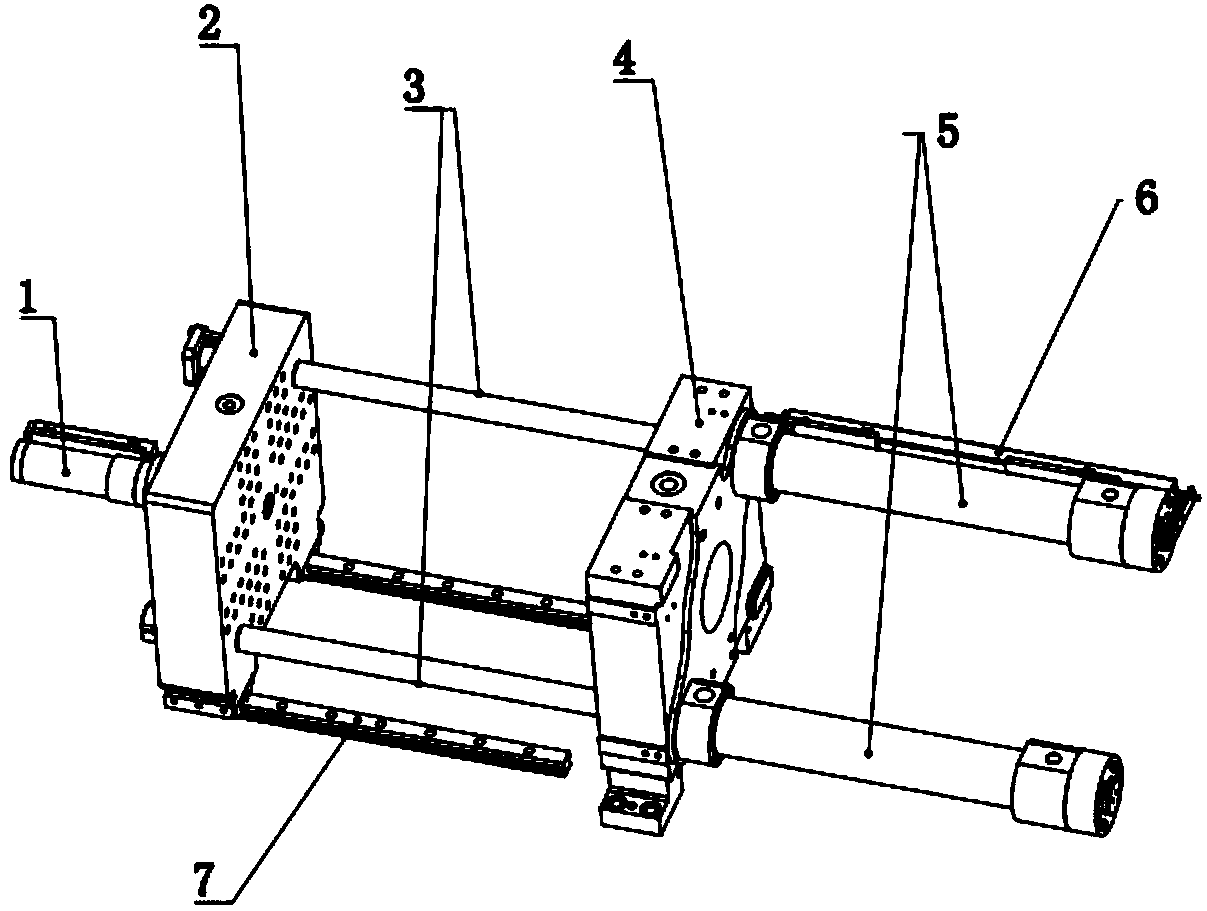

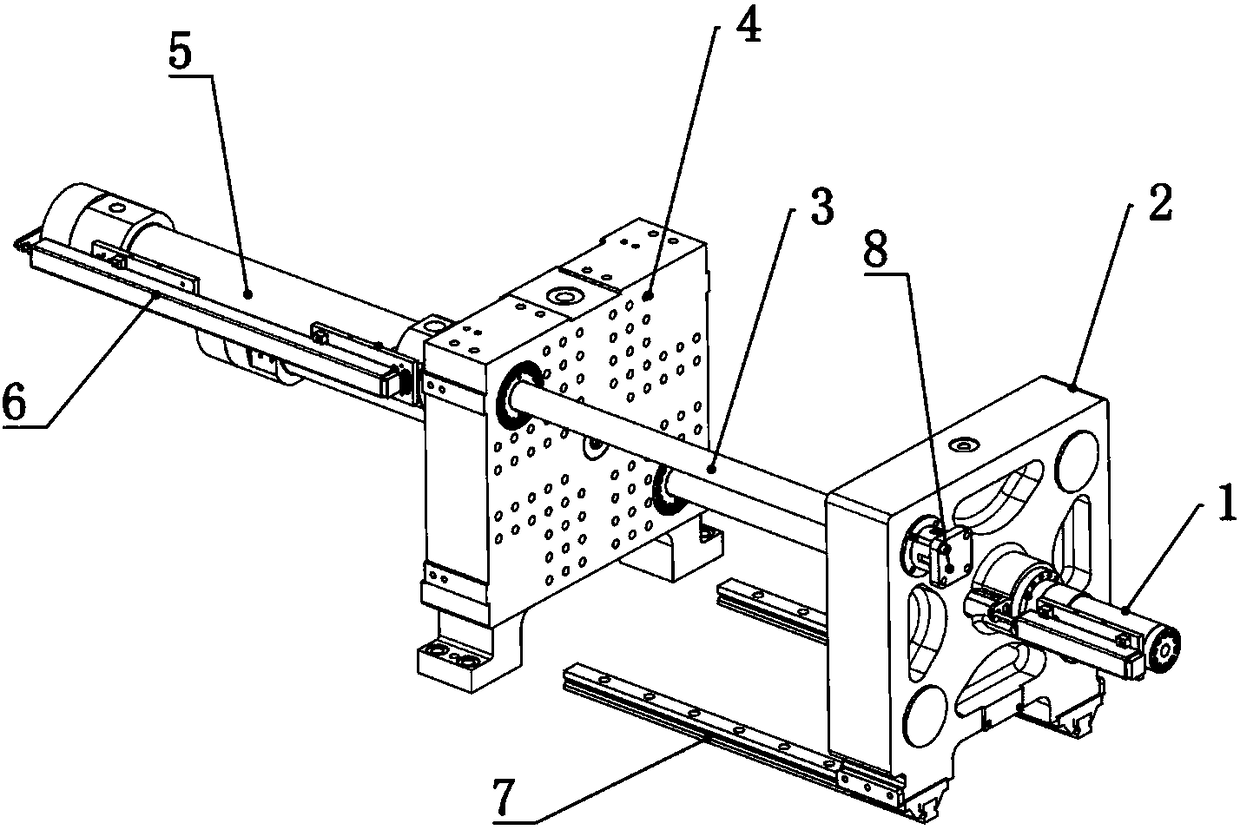

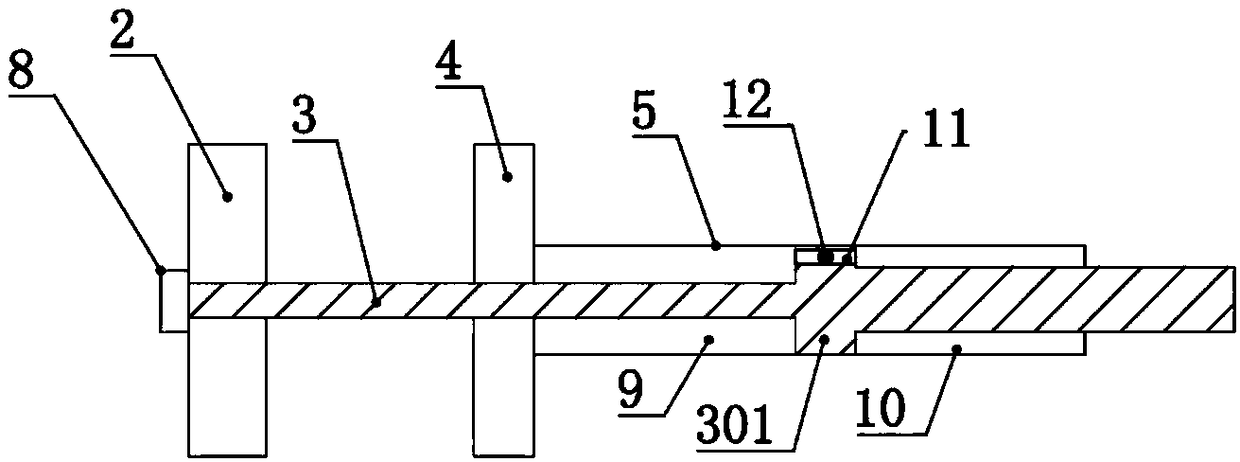

[0033] Provide an injection molding machine mold clamping mechanism, such as Figure 1-Figure 2 As shown, the fixed template 4 and the movable template 2 arranged at parallel intervals are included, and the clamping cylinder 5 is arranged at the end of the fixed template 4 away from the movable template 2, and the clamping cylinder 5 can be arranged in parallel at the diagonally opposite corner of the fixed template 4 Two groups or four groups are arranged symmetrically at the four corners of the fixed template 4. Based on cost considerations, it is preferable to arrange two groups of clamping cylinders 5 obliquely. Through the fixed template 4 and the movable template 2 arranged in parallel, a locking stud is set on the tie rod 3 at the end of the movable template 2 away from the fixed template 4 to fix the tie rod 3 and the movable template 2, and at the joint between the tie rod 3 and the fixed template 4 A lubricating guide sleeve is provided, and the lubricating guide slee...

Embodiment 2

[0037] In this embodiment, on the basis of Embodiment 1, a locking mechanism is added to increase the overall mold locking capability.

[0038] Such as Figure 4-Figure 5 As shown, a second through hole 401 is provided at the other two opposite corners of the movable platen 2 where the clamping cylinder 5 is not provided. Between the fixed platen 4 and the second through hole 401, there is a piston The expansion and contraction of the rod acts as a guide rod 13 that moves telescopically relative to the second through hole 401. A locking mechanism that limits the radial movement of the guide rod 13 is provided on the side of the movable template 2 away from the fixed template 4. The drive mechanism on the midpoint of the line connecting the centers of the two guide rods 13 and the clamping module that clamps the guide rod 13 under the drive of the drive mechanism, the drive mechanism is two locking cylinders 14 facing away from each other, and the locking cylinder 14 The pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com