Poly(ethylene-r-norbornene/ethylene) segmented copolymer synthesized by utilizing chain shuttling method

A technology of multi-block copolymer and norbornene, which is applied in the field of synthesizing poly(ethylene-r-norbornene/ethylene) multi-block copolymer by chain shuttling, can solve the problem of poor catalyst tolerance, few types, difficult issues of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

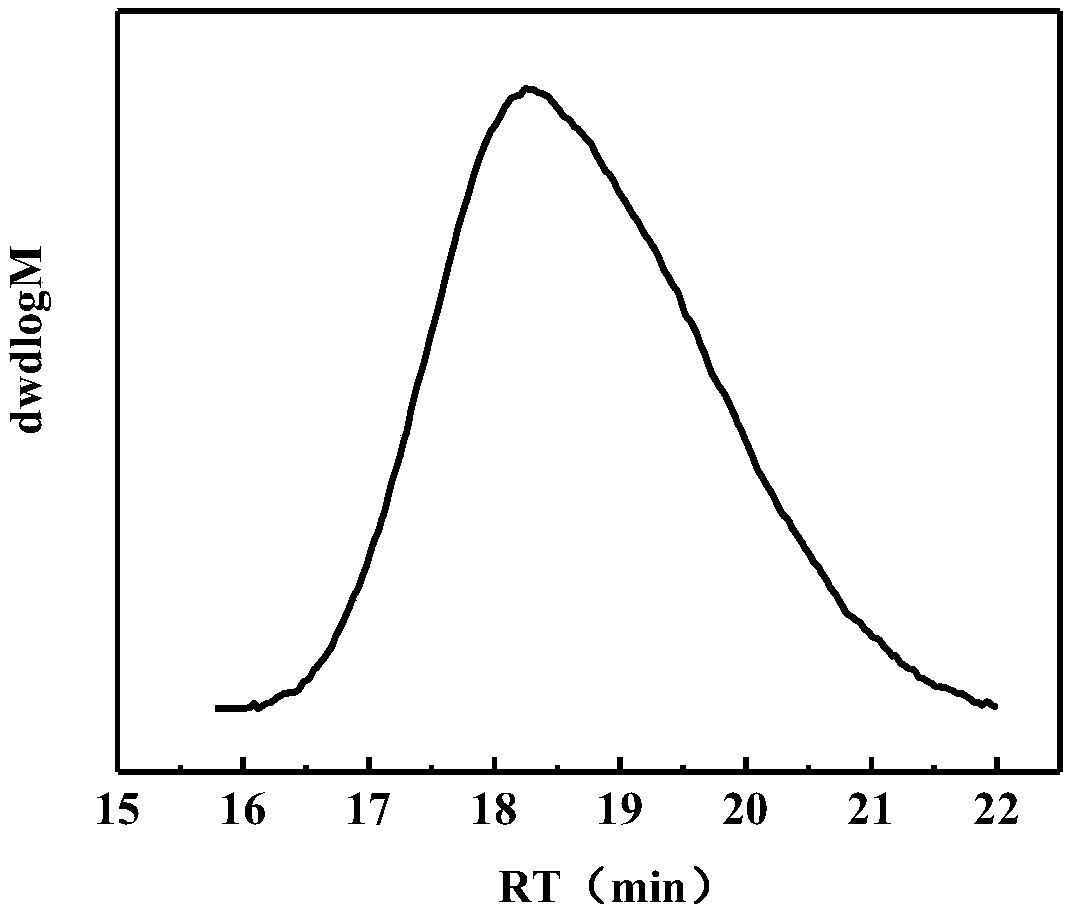

Embodiment 1

[0046] In this example, the polymerization temperature is 50°C, the ethylene pressure is 1 atm, the molar content of diethyl zinc is 10 times that of the mixed catalyst, and the mixed catalyst Rac-ethyl bridged dichlorodiindene zirconium A and Rac-3-tert-butyl Chain shuttling polymerization with a polymerization time of 6 minutes under the condition that the molar ratio of substituted methine bridged dichlorodiindene zirconium B is 3:1.

[0047] Chain shuttling polymerization in this embodiment includes the following steps:

[0048] (1) Weigh and equip the chain shuttling catalyst: weigh Rac-ethyl bridged diindene zirconium dichloride and Rac-3-tert-butyl substituted methine bridged diindene dichloride with an analytical balance in the glove box The zirconium mixed catalyst, whose molar ratio is 3:1, is fully dissolved in toluene, and is reserved for later use.

[0049] (2), adding of polymerized monomer and regulating polymerization temperature: adding the comonomer norborne...

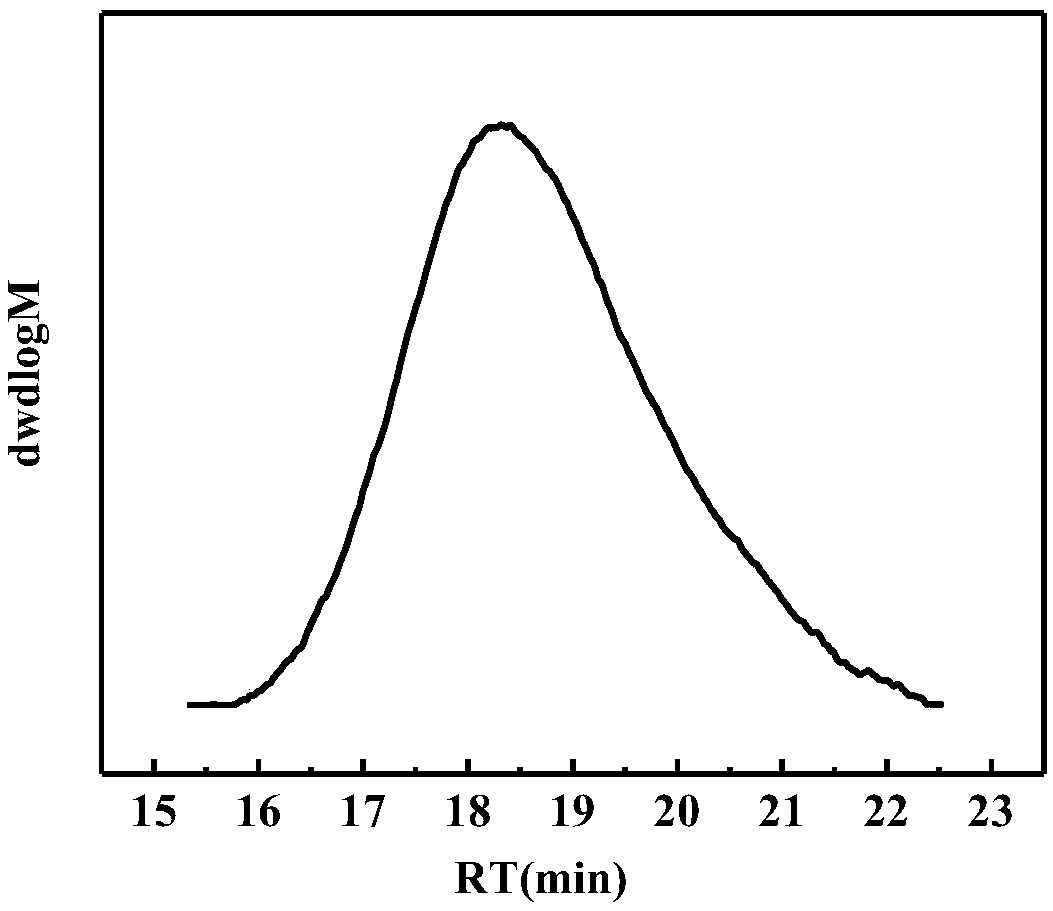

Embodiment 2

[0057] In this example, the polymerization temperature is 50°C, the ethylene pressure is 1 atm, the molar content of diethyl zinc is 10 times that of the mixed catalyst, and the mixed catalyst Rac-ethyl bridged dichlorodiindene zirconium A and Rac-3-tert-butyl Chain shuttling polymerization with a polymerization time of 15 minutes under the condition that the molar ratio of substituted methine bridged dichlorodiindene zirconium B is 3:1.

[0058] Chain shuttling polymerization in this embodiment includes the following steps:

[0059] (1) Weigh and equip the chain shuttling catalyst: weigh Rac-ethyl bridged diindene zirconium dichloride and Rac-3-tert-butyl substituted methine bridged diindene dichloride with an analytical balance in the glove box The zirconium mixed catalyst, whose molar ratio is 3:1, is fully dissolved in toluene, and is reserved for later use.

[0060] (2), the addition of polymerized monomers and the adjustment of the polymerization temperature: the comono...

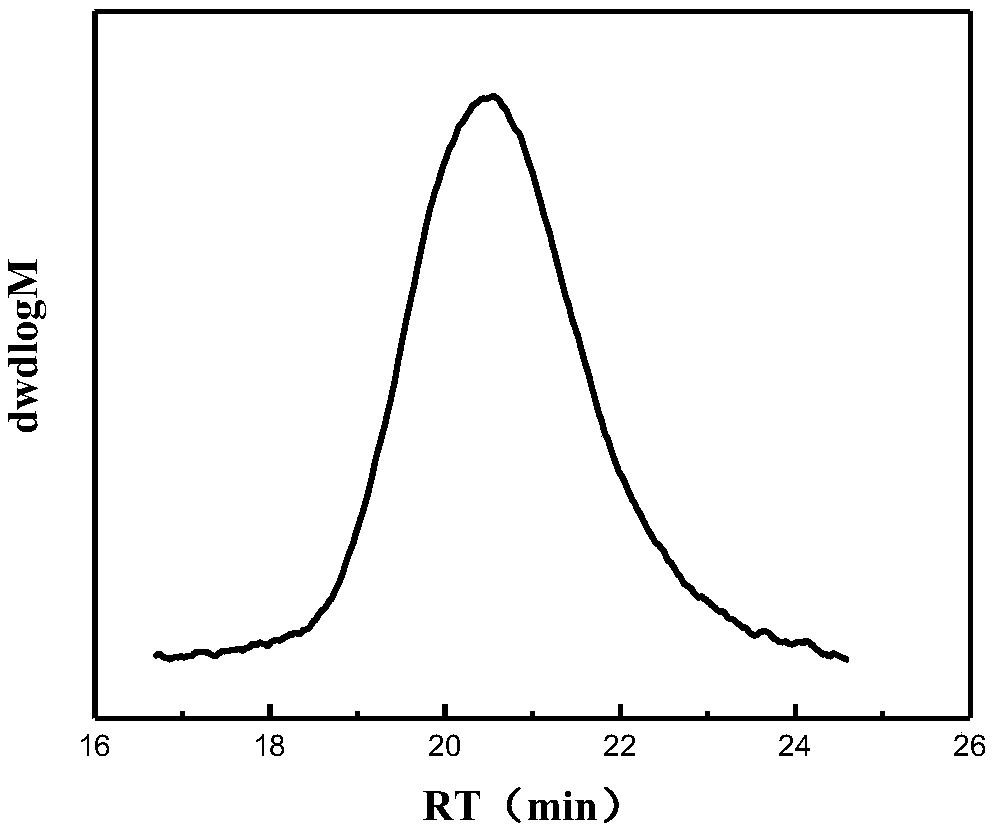

Embodiment 3

[0067] In this example, the polymerization temperature is 70°C, the ethylene pressure is 1 atm, the molar content of diethyl zinc is 15 times that of the mixed catalyst, and the mixed catalyst Rac-ethyl bridged dichlorodiindene zirconium A and Rac-3-tert-butyl Chain shuttling polymerization with methine bridged dichlorodiindene zirconium B molar ratio of 1:1 and polymerization time of 10 min.

[0068] Chain shuttling polymerization in this embodiment includes the following steps:

[0069] (1) Weigh and equip the chain shuttling catalyst: weigh Rac-ethyl bridged diindene zirconium dichloride and Rac-3-tert-butyl substituted methine bridged diindene dichloride with an analytical balance in the glove box The zirconium mixed catalyst, whose molar ratio is 1:1, is fully dissolved in toluene, and is reserved for later use.

[0070] (2), adding of polymerized monomer and regulating polymerization temperature: adding the comonomer norbornene dissolved in toluene in the polymerization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com