500 MPa-grade V-containing micro-alloyed high-strength-yield-ratio anti-seismic steel bar wire rod and production method thereof

A technology of anti-seismic steel bars and production methods, which is applied in the fields of iron and steel metallurgy and steel rolling, can solve the problems of poor anti-seismic performance of micro-alloy steel bars, and achieve the effect of large yield strength surplus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

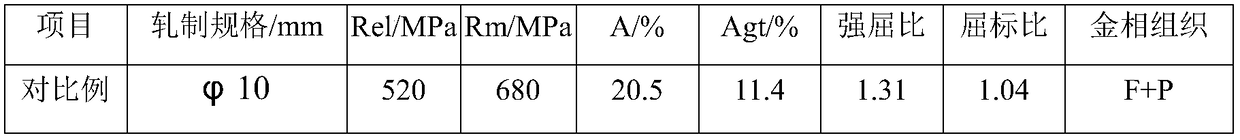

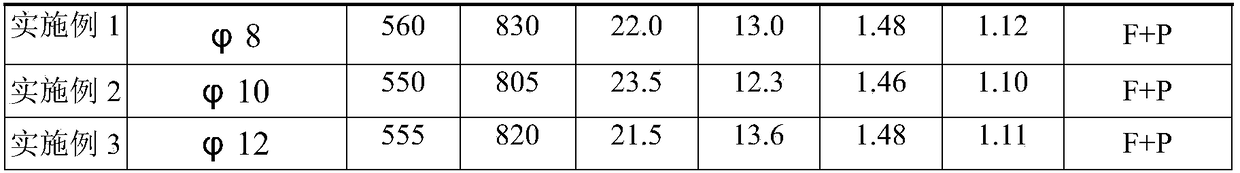

Examples

Embodiment 1

[0033] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0034] After pre-desulfurization of molten iron, molten iron and scrap steel are added to a converter with a nominal capacity of 120 tons, and then the top-bottom combined blowing smelting is carried out until the C content in the molten steel is less than 0.06%, and the P and S contents are less than 0.035%. Add FeSi, FeMn, VN16, FeV alloys and anthracite to the molten steel in the process of 1 / 3~2 / 3 to carry out alloying of Si, Mn, V and C elements, among which VN16 alloy is added quantitatively at 0.62kg per ton of steel, and the rest V Then make up with FeV alloy, and control the N content of molten steel to be 0.0100%; after the molten steel reaches the small platform behind the furnace, the ladle is immediately connected to the pipeline, and nitrogen is blown into the molten steel in the ladle for 4 minutes to make the added various The alloy is f...

Embodiment 2

[0036] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0037] After pre-desulfurization of molten iron, molten iron and scrap steel are added to a converter with a nominal capacity of 120 tons, and then the top-bottom combined blowing smelting is carried out until the C content in the molten steel is less than 0.06%, and the P and S contents are less than 0.035%. Add FeSi, FeMn, VN16, FeV alloys and anthracite to the molten steel in the process of 1 / 3~2 / 3 to carry out alloying of Si, Mn, V and C elements, among which VN16 alloy is added quantitatively at 0.68kg per ton of steel, and the rest V Then supplement it with FeV alloy, control the N content of molten steel to be 0.0110%; after the molten steel reaches the small platform behind the furnace, the ladle is immediately connected to the pipeline, and nitrogen is blown into the molten steel in the ladle for 4 minutes to make the added various The alloy is...

Embodiment 3

[0039] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0040] After pre-desulfurization of molten iron, molten iron and scrap steel are added to a converter with a nominal capacity of 120 tons, and then the top-bottom combined blowing smelting is carried out until the C content in the molten steel is less than 0.06%, and the P and S contents are less than 0.035%. Add FeSi, FeMn, VN16, FeV alloys and anthracite to the molten steel in the process of 1 / 3~2 / 3 to carry out alloying of Si, Mn, V and C elements, among which VN16 alloy is added quantitatively at 0.75kg per ton of steel, and the rest V Then make up with FeV alloy, and control the N content of molten steel to be 0.0115%; after molten steel reaches the small platform behind the furnace, the ladle is immediately connected to the pipeline, and nitrogen is blown into the molten steel in the ladle for 4 minutes to make the added various The alloy is fully...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com