Hot dip galvanized sling enabling surfaces of workpieces to be resistant to zinc ash

A workpiece surface, hot-dip galvanizing technology, applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve problems such as easy adhesion, affect product quality, etc., and achieve the effect of ensuring the film breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

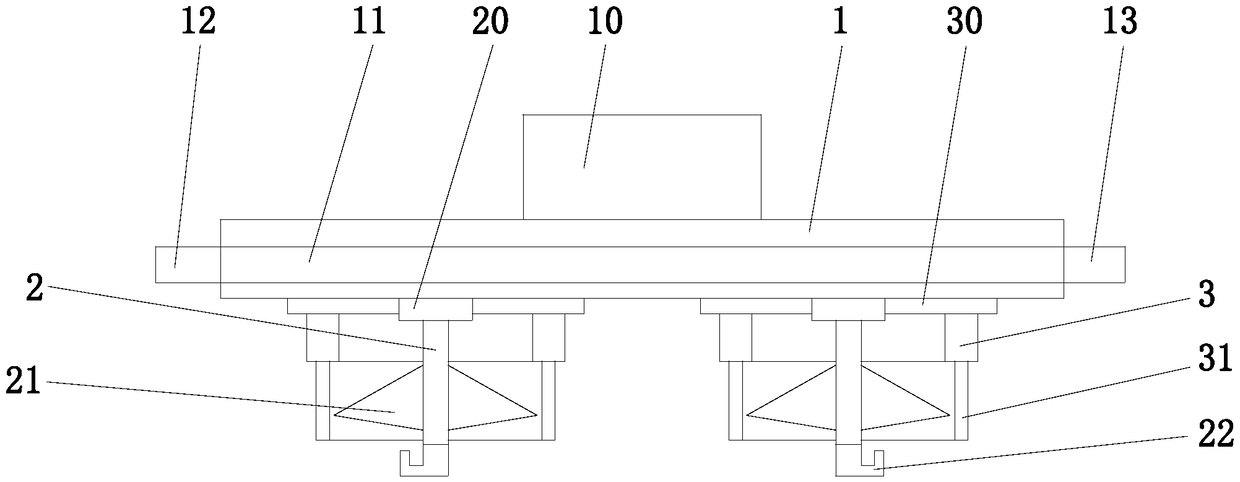

[0015] refer to figure 1 , the present invention is a kind of hot-dip galvanized hanger that the workpiece surface is not easy to adhere to zinc ash, comprising base 1, first lifting device 20, first lifting rod 2, suspension hook 22, rupture block 21, described base 1 is provided with several first lifting rods 2, the top of the first lifting rods 2 is connected with the first lifting device 20, the first lifting device 20 is fixed on the bottom of the base 1, and the bottom of the first lifting rods 2 is provided with a Because of the hook 22 that hangs the workpiece, a membrane rupture block 21 is fixed on the first elevating rod 2, the upper surface of the membrane rupture block 21 is a conical surface, and the lower projection of the membrane rupture block 21 covers the lower projection of the workpiece. The outside of the rupture block 21 is covered with a shielding ring 31. The inner diameter of the shield ring 31 is slightly larger than the diameter of the rupture bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com