Sweat steaming clothing face fabric and preparation technology thereof

A preparation process and fabric technology, which is applied in the field of textile fabrics, can solve problems such as single windproof function, stuffy wearing, easy swelling and deformation, etc., and achieve the effects of accelerating metabolism, good weather resistance, and reducing temperature loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0029] A fabric for steaming clothes, the fabric includes a face cloth layer and a film layer from top to bottom; the face cloth layer is a knitted fabric or a woven fabric, and the composition is polyester or nylon; the film layer is New PU silver sweat steaming functional film.

[0030] The total gram weight of the sweat steaming functional clothing fabric is 45g / m 2 . The grammage of the face cloth layer is 30g / m 2 , the fabric of the face fabric is 20D polyester or nylon fabric.

[0031] The moisture permeability of the new PU silver sweat steaming functional film is: 900g / m2.24H, and the water pressure resistance is: above 3500 mmH 2 O. The appearance of the new PU silver sweat steaming functional film is a silver metal film with a non-volatile content of 26% and a viscosity of 30dpas / 25°C. It is composed of DMF / EtAC with a silver content of 4%.

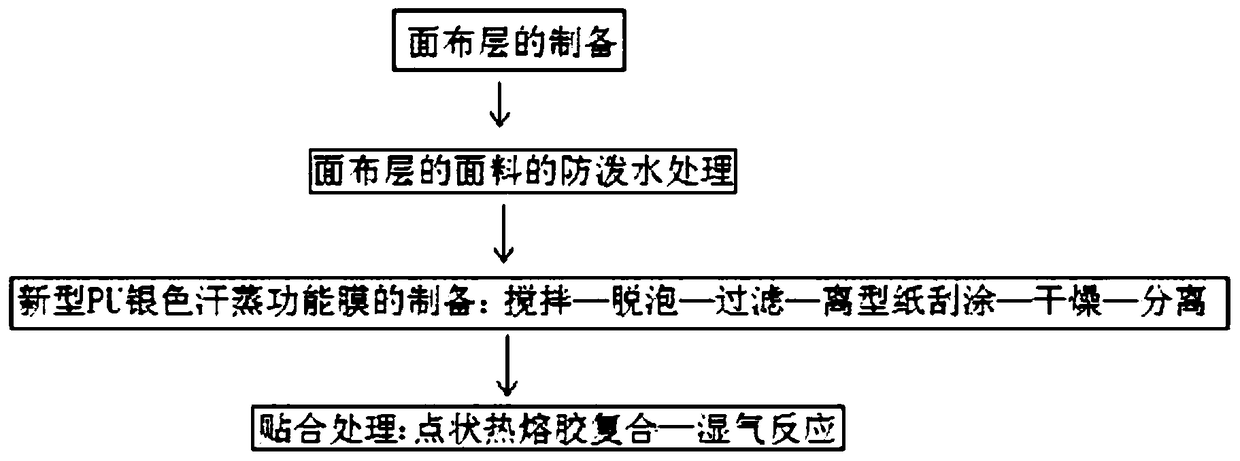

[0032] Such as figure 1 Shown, the preparation technology of described steaming suit fabric, comprises the steps:

[00...

specific Embodiment 2

[0041]A fabric for steaming clothes, the fabric includes a face cloth layer and a film layer from top to bottom; the face cloth layer is a knitted fabric or a woven fabric, and the composition is polyester or nylon; the film layer is New PU silver sweat steaming functional film.

[0042] The total gram weight of the sweat steaming functional clothing fabric is 270g / m 2 . The grammage of the face cloth layer is 250g / m 2 , the fabric of the face fabric is 75D polyester or nylon fabric.

[0043] The moisture permeability of the new PU silver sweat steaming functional film is: 900g / m2.24H, and the water pressure resistance is: above 3500 mmH 2 O. The appearance of the new PU silver sweat steaming functional film is a silver metal film with a non-volatile content of 36% and a viscosity of 60dpas / 25°C. It is composed of DMF / EtAC with a silver content of 6%.

[0044] Such as figure 1 Shown, the preparation technology of described steaming suit fabric, comprises the steps:

[0...

specific Embodiment 3

[0053] A fabric for steaming clothes, the fabric includes a face cloth layer and a film layer from top to bottom; the face cloth layer is a knitted fabric or a woven fabric, and the composition is polyester or nylon; the film layer is New PU silver sweat steaming functional film.

[0054] The total gram weight of the sweat steaming functional clothing fabric is 160g / m 2 . The grammage of the face cloth layer is 140g / m 2 , the fabric of the face fabric is 55D polyester or nylon fabric.

[0055] The moisture permeability of the new PU silver sweat steaming functional film is: 900g / m2.24H, and the water pressure resistance is: above 3500 mmH 2 O. The appearance of the new PU silver sweat steaming functional film is a silver metal film with a non-volatile content of 29% and a viscosity of 50dpas / 25°C. It is composed of DMF / EtAC with a silver content of 5%.

[0056] Such as figure 1 Shown, the preparation technology of described steaming suit fabric, comprises the steps:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com