Airplane part ultra-high precision end face surface flatness detecting imaging device and detecting method

A flatness detection and imaging device technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of low detection efficiency and measurement accuracy, difficulty in obtaining accurate measurement results, and lack of detection efficiency imaging devices, etc. High efficiency and measurement accuracy, improved light source gathering, and improved detection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

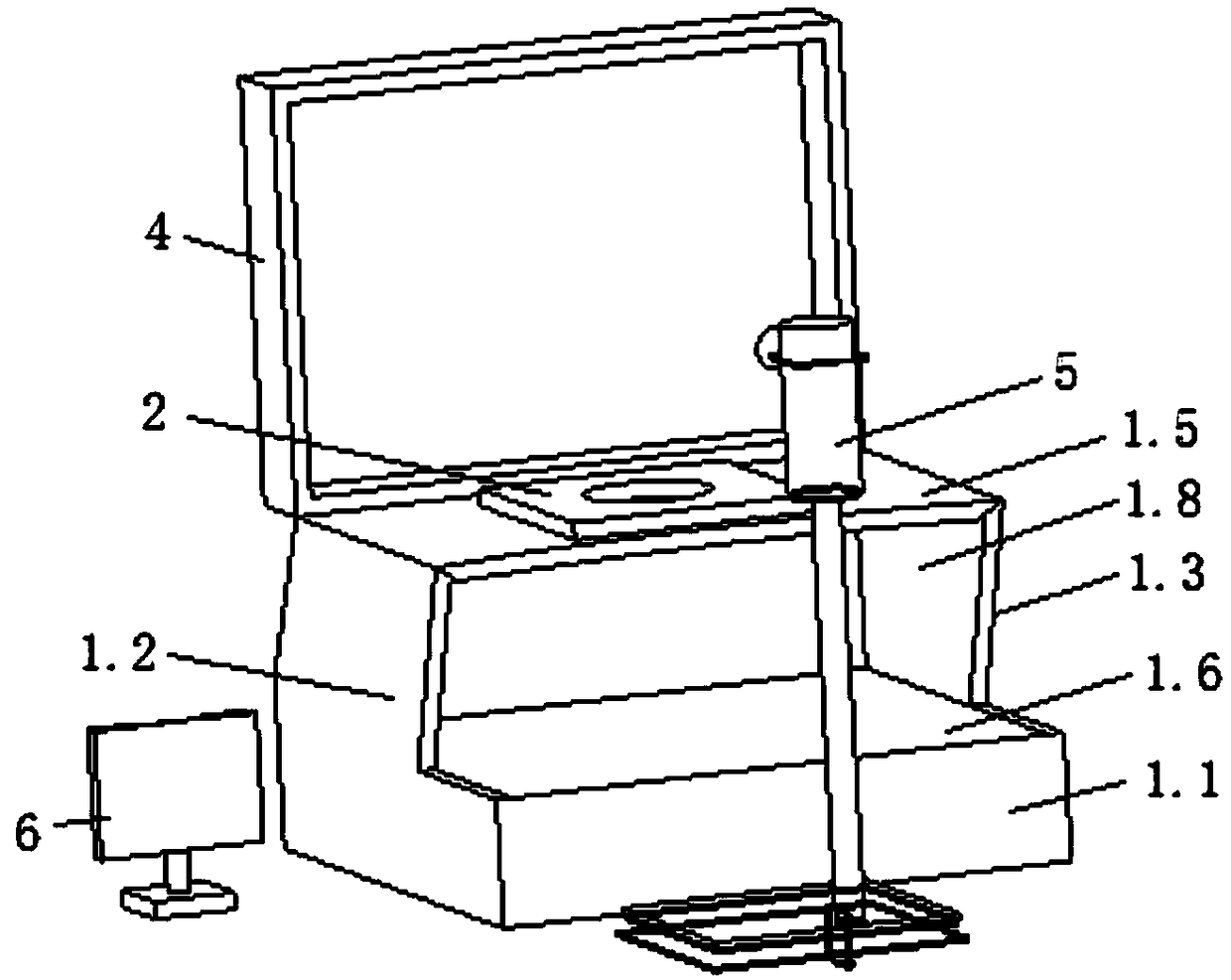

[0040] An ultra-high-precision end face flatness detection imaging device for aviation parts, comprising a solid wood main body box, a flat crystal tray 2, a flat crystal 3, a flat crystal protective cover 4, an interference light source, a CCD sensor, a universal adjustment bracket 5 and a computer 6. The schematic diagram of the three-dimensional structure is as figure 1 shown.

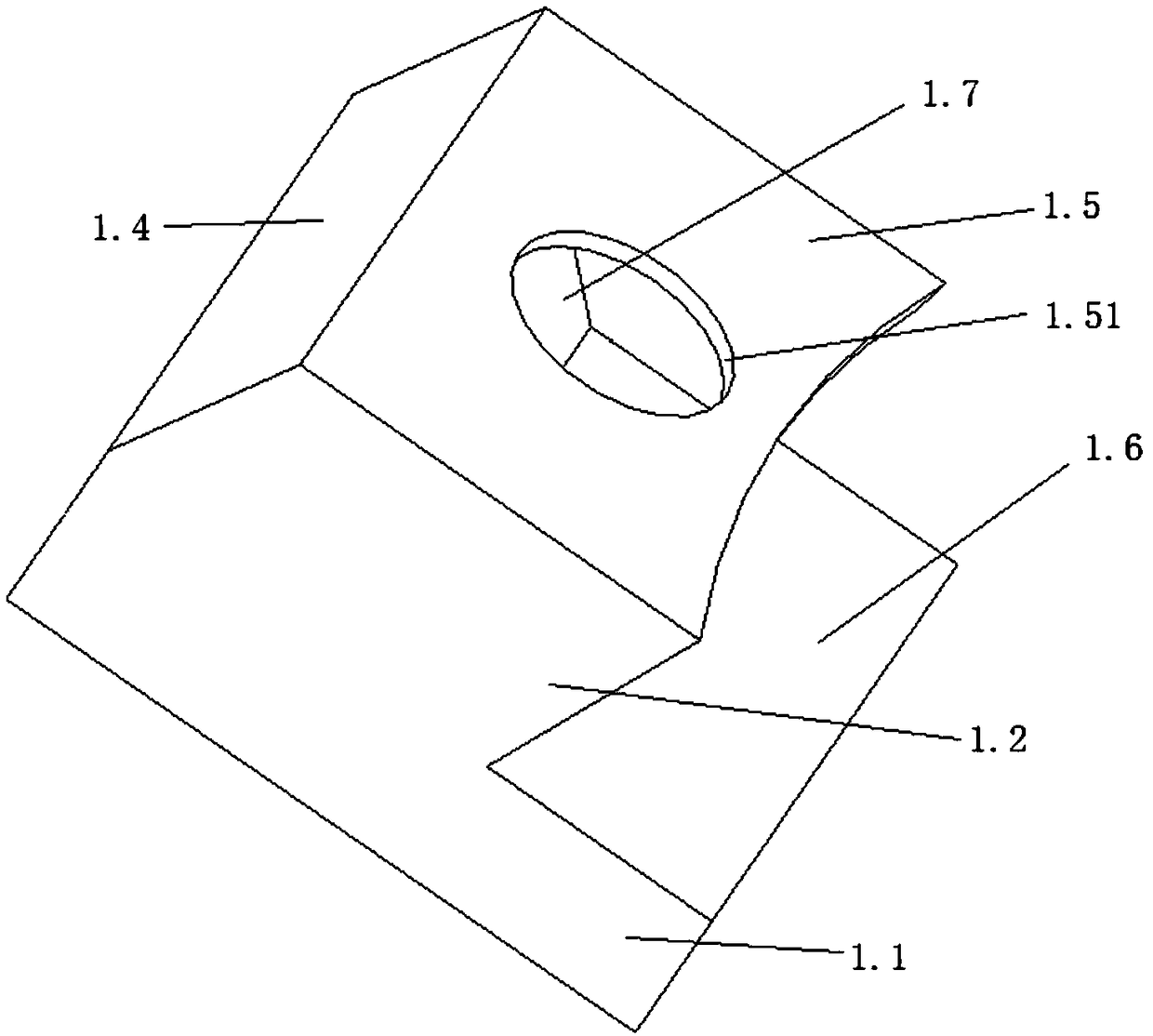

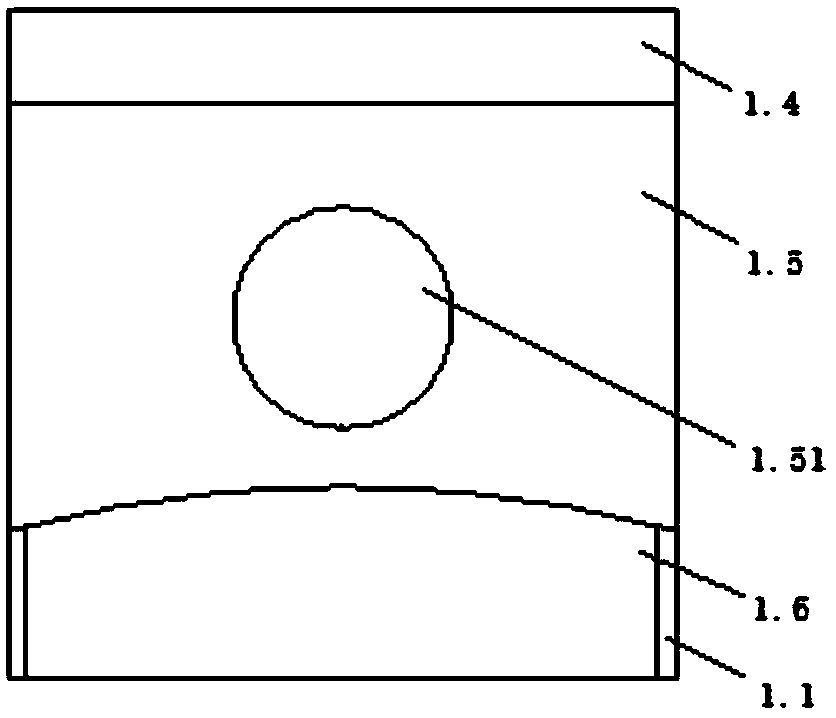

[0041] The structure of the solid wood main box is as follows figure 2 with image 3 , the solid wood main box includes base 1.1, left side panel 1.2, right side panel 1.3, rear side panel 1.4 and upper panel 1.5, base 1.1, left side panel 1.2, right side panel 1.3, rear side panel 1.4 and upper panel 1.5 A cavity, the front of which communicates with the outside world. The left side plate 1.2, the right side plate 1.3 and the rear side plate 1.4 are all instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com